Calculation method for pulling-out force of shaft seizure bearing bush and pulling-out method

A calculation method and pull-out force technology, applied in the calculation field of bearing bush pull-out force, can solve the problems of prolonging emergency repair time, difficult work, and increasing enterprise cost, so as to avoid underestimation, shorten emergency repair time, and reduce enterprise cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

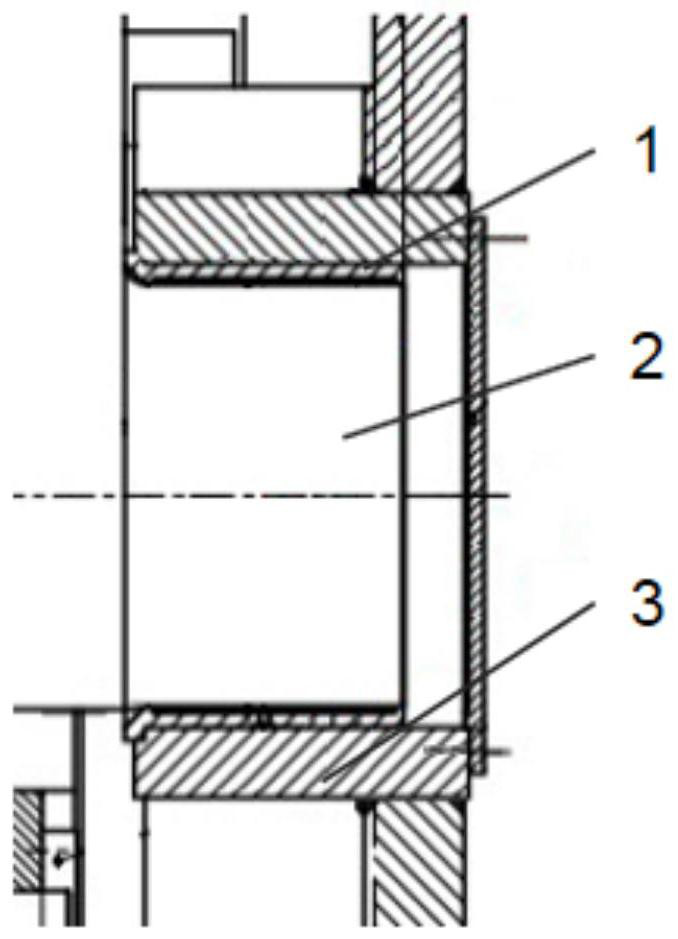

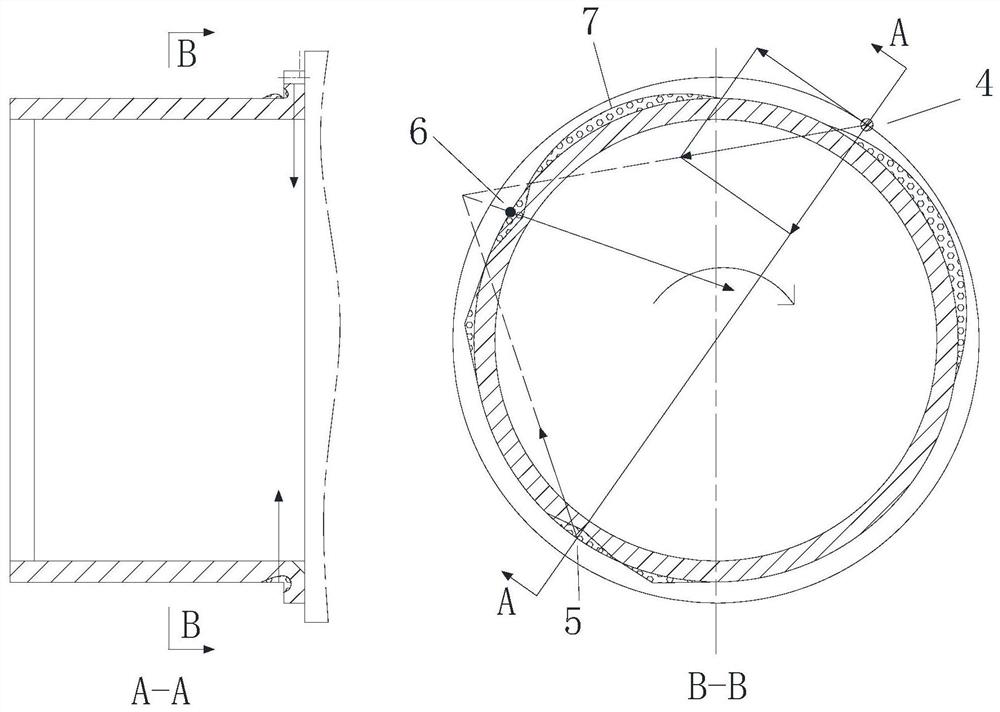

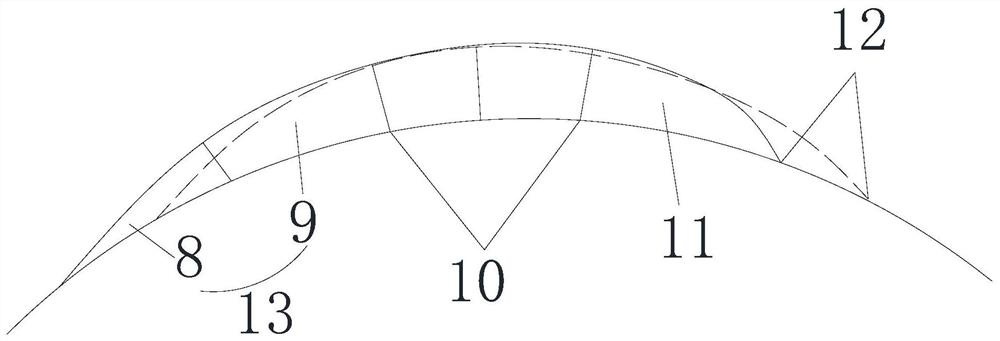

[0100] A cold shear in a factory caused the bearing bush to burn out and the main shaft to die due to lack of oil. The bearing bush is made of ZCuAl 9 Fe 4 Ni 4 Mn 2 , The bearing bush and the bearing pad seat are designed as a transition fit, and the interference is -0.04 ~ 0.063mm. The circular pin with a diameter of 12 × 20mm is used on the end face of the bearing pad seat to realize the circumferential direction of the bearing pad to prevent the bearing pad from rotating. When the accident occurs, the bearing bush and the main shaft are seized and there is no relative rotation, and the bearing bush and the bearing pad seat rotate relative to each other. The specific structure is as follows: figure 1 shown.

[0101] In the above embodiment, the positioning in the circumferential direction of the bearing bush is realized with the positioning round pin, and the calculation method and the extraction method are as follows:

[0102] Step 1: Calculate the resistance Fs caused...

Embodiment 2

[0114] In a factory, the cutting arm of the flying shear was burnt out and the shaft was bitten due to lack of oil. The material of the bearing pad is ZQAL7-1.5-1.5, the transition fit between the bearing pad and the bearing pad seat is designed, and the interference is -0.04~0.033mm. The bearing pad is positioned in the circumferential direction through two hook keys to prevent the bearing pad from rotating. When the accident occurred, the bearing bush and the shaft were seized and there was no relative rotation, and there was no relative rotation between the bearing bush and the bearing pad seat.

[0115] In the above embodiment, the bearing bush circumferential direction positioning is realized with two hook keys, and the calculation process is as follows:

[0116] Step 1: Calculate the resistance Fs caused by the tearing off of the outer surface of the bearing bush;

[0117] Resistance Fs=λδA / 9800,

[0118] Analyzing the positioning method of the bearing bush, one side (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com