Outer coating film type thin film capacitor winding machine

A film capacitor and winding machine technology, applied in the direction of winding capacitor machines, etc., can solve the problems of scratches and wear, capacitors are easy to adhere to dust, etc., and achieve the effects of improving quality, convenient operation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

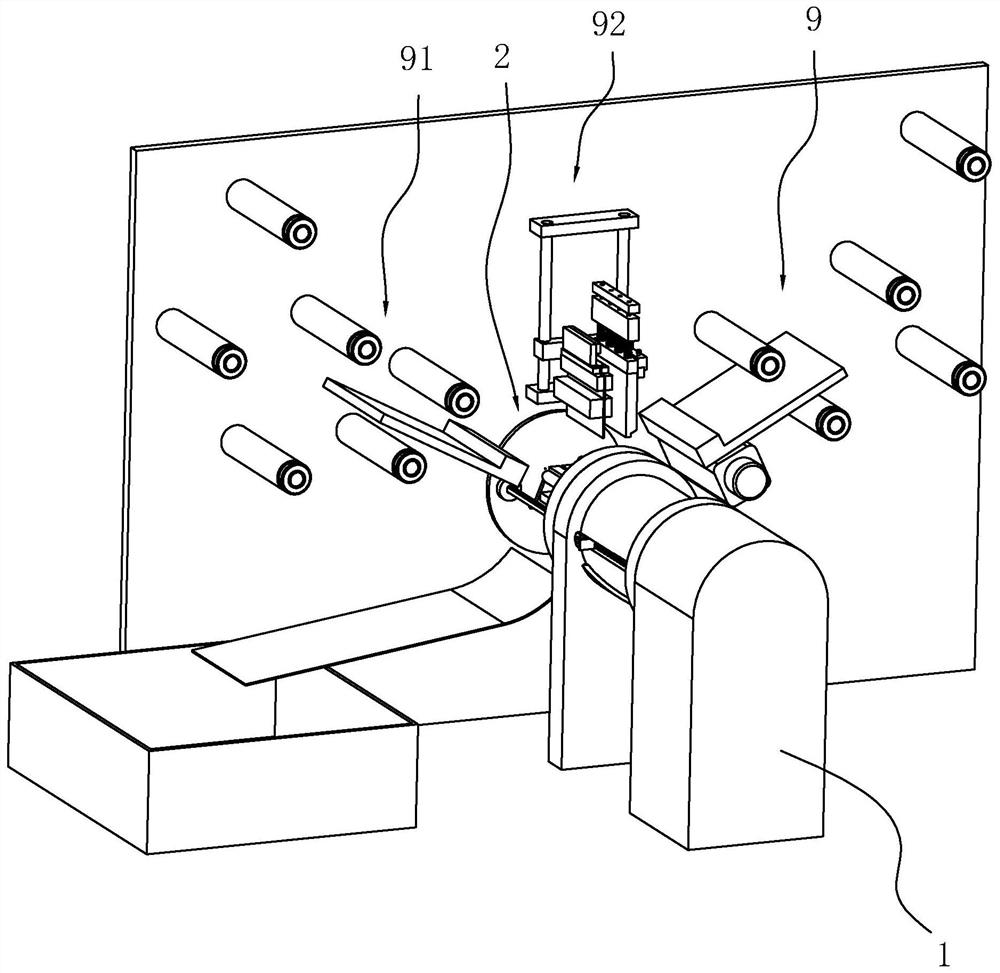

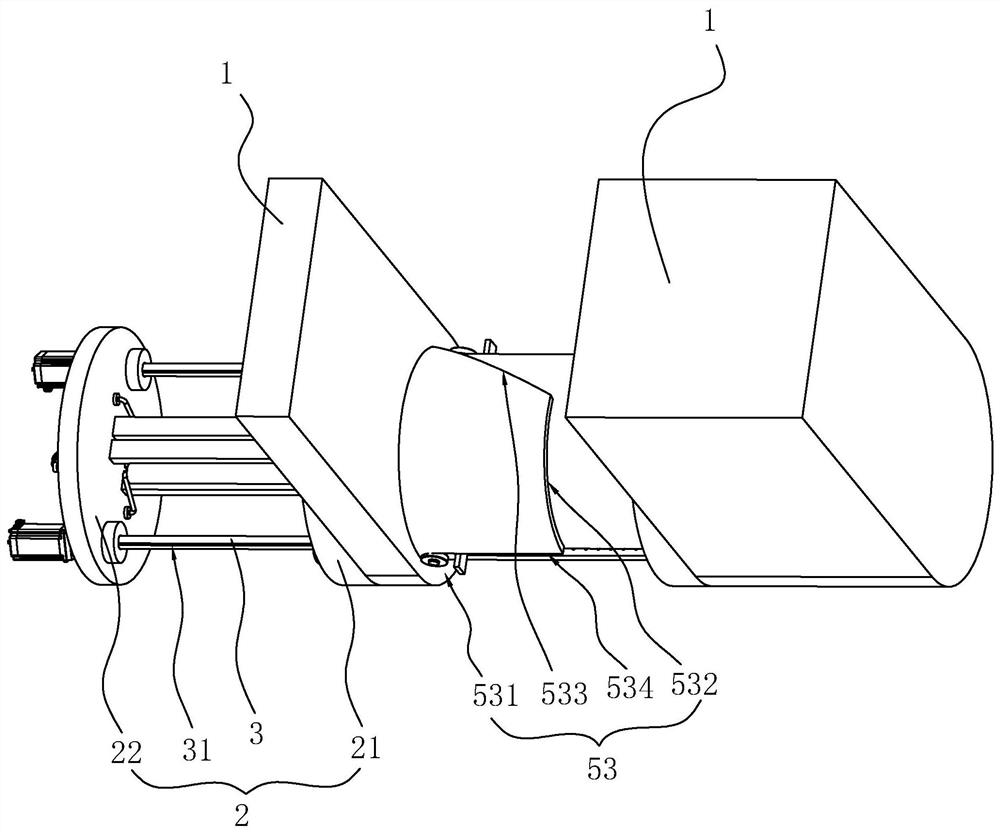

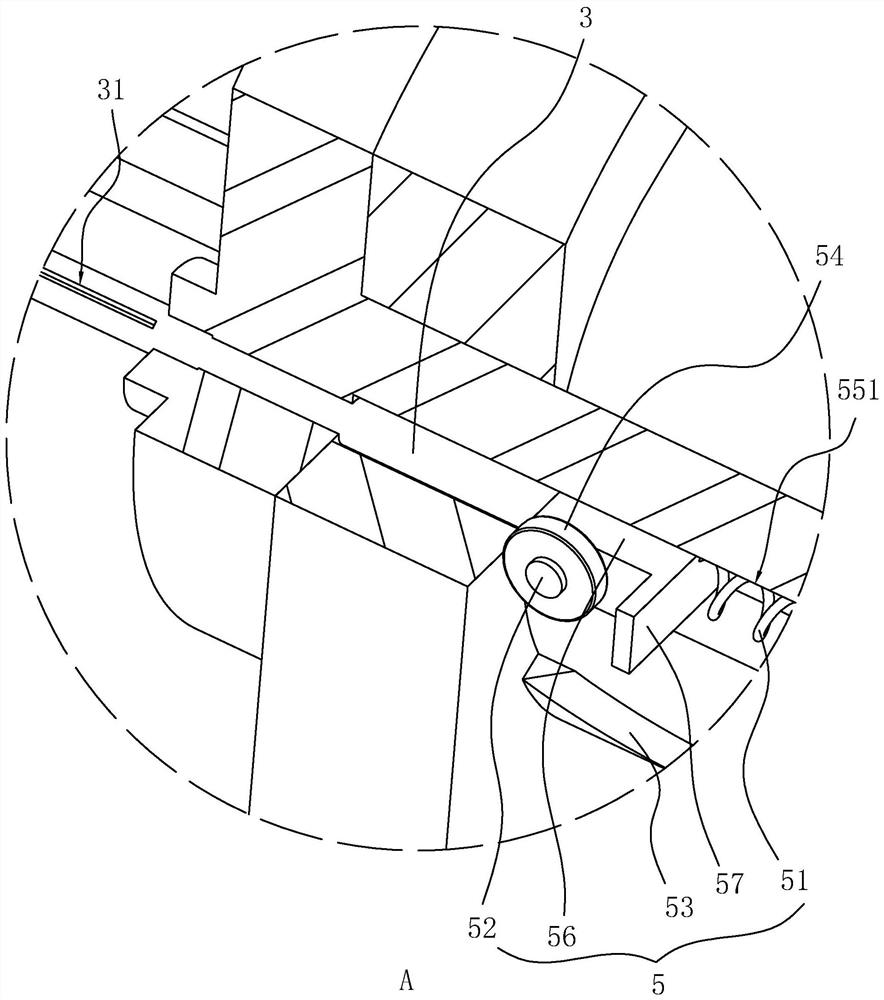

[0040] The embodiment of the present application discloses a winding machine for an outer-wrapped film capacitor. refer to figure 1 , 2 , the rotary machine comprises a frame 1, on which a mandrel 2 is rotatably installed, and the mandrel 2 includes a first mounting plate 21 and a second mounting plate 22 positioned at two ends, the first mounting plate 21, the second mounting plate 22 It is arranged coaxially with the mandrel 2. On the first mounting plate 21 , a clamp pin 3 is slidably installed along the working axis, and is used for clamping the film of the capacitor. The axis of the clamping needle 3 is eccentric to the axis of the first mounting plate 21 , and when the clamping needle 3 moves along the circumference of the mandrel 2 , it successively passes through the capacitor film winding station 9 and the capacitor protective film coating station 91 .

[0041] refer to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap