Manufacturing method of low-fat and low-sugar light food main fiber rod

A fiber stick, principled technology, applied in the field of light food fiber stick food, can solve problems such as body and health concerns, affecting normal life, etc., to achieve the effects of promoting nutrient absorption, improving human immunity, and lowering cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

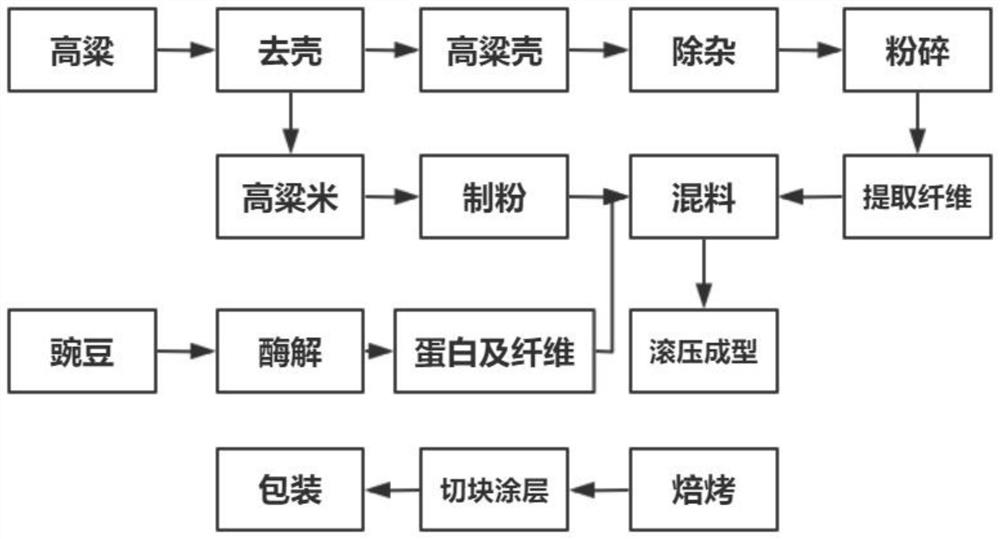

Image

Examples

Embodiment 1

[0019] A method for making a low-fat, low-sugar light food fiber bar, comprising the following steps:

[0020] S1. Dehulling and milling: the cleaned sorghum is dehulled by a grain peeling machine, the dehulled sorghum rice is crushed and sieved by a step-by-step layered milling method, and it is ground into powder, and the ground sorghum is ground into powder Powder 120 mesh sieve;

[0021] S2. Extraction of fibers: put the removed shell through a pulverizer to obtain sorghum husk powder, use acid-soluble alkali precipitation method, weigh 15g of sorghum husk powder into a 250ml beaker, add 150ml to make a slurry with a mass ratio of 1:10 , and adjust the pH value to 4.0 with 1mol / L hydrochloric acid solution, shake in an ultrasonic cleaner for 2.5 hours, filter and remove the reaction solution, add a certain amount of sodium hydroxide solution to react for 1 hour, filter and remove the hydrolyzate, and dry to constant weight. finished product;

[0022] S3. Pea enzymatic hy...

Embodiment 2

[0027] A method for making a low-fat, low-sugar light food fiber bar, comprising the following steps:

[0028] S1. Dehulling and milling: the cleaned sorghum is dehulled by a grain peeling machine, the dehulled sorghum rice is crushed and sieved by a step-by-step layered milling method, and it is ground into powder, and the ground sorghum is ground into powder Powder 120 mesh sieve;

[0029] S2. Extraction of fibers: put the removed shell through a pulverizer to obtain sorghum husk powder, use acid-soluble alkali precipitation method, weigh 17g of sorghum husk powder into a 250ml beaker, add 170ml to adjust to a slurry liquid with a mass ratio of 1:10 , and adjust the pH value to 4.0 with 1mol / L hydrochloric acid solution, and shake in an ultrasonic cleaner for 2.7h, filter to remove the reaction solution, add a certain amount of sodium hydroxide solution to react for 1.3h, then filter to remove the hydrolyzate, and dry to constant weight , the finished product is obtained; ...

Embodiment 3

[0035] S1. Dehulling and milling: the cleaned sorghum is dehulled by a grain peeling machine, the dehulled sorghum rice is crushed and sieved by a step-by-step layered milling method, and it is ground into powder, and the ground sorghum is ground into powder Powder 120 mesh sieve;

[0036] S2. Extraction of fibers: Put the removed shell through a pulverizer to obtain sorghum husk powder, use acid-soluble alkali precipitation method, weigh 20g of sorghum husk powder into a 250ml beaker, add 200ml to make a slurry with a mass ratio of 1:10 , and adjust the pH value to 4.0 with 1mol / L hydrochloric acid solution, shake in an ultrasonic cleaner for 3 hours, filter and remove the reaction solution, add a certain amount of sodium hydroxide solution to react for 1.5 hours, filter and remove the hydrolyzate, dry to constant weight, finished product;

[0037] S3. Pea enzymatic hydrolysis: use specific enzymatic hydrolysis to remove starch, retain high-quality protein and insoluble diet...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap