Chemical product mixing and stirring tank

A technology for mixing and mixing chemical products, which is applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., and can solve problems such as poor material circulation, inability to get a good reaction, and poor mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

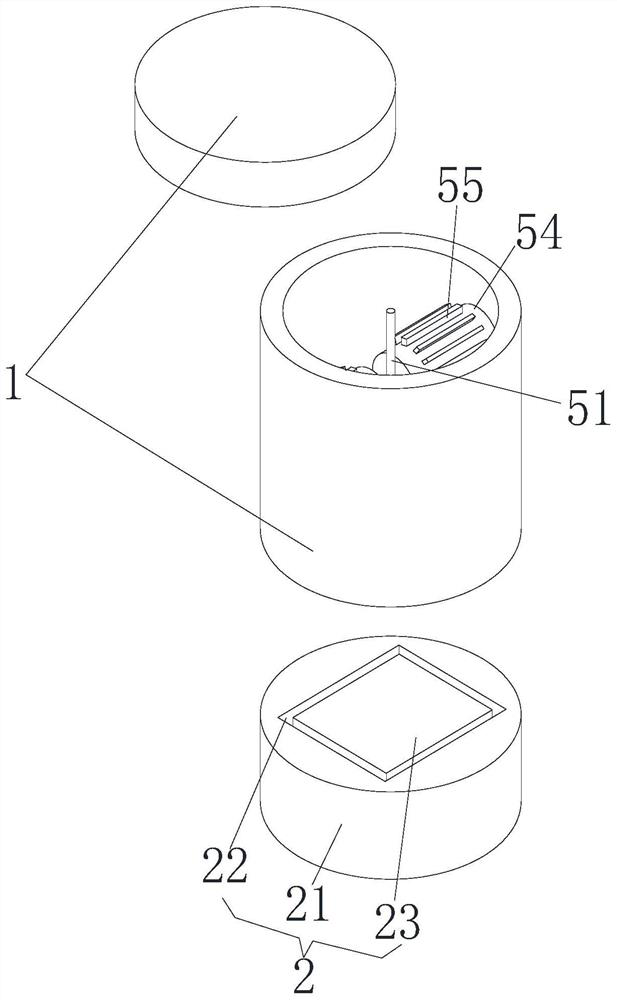

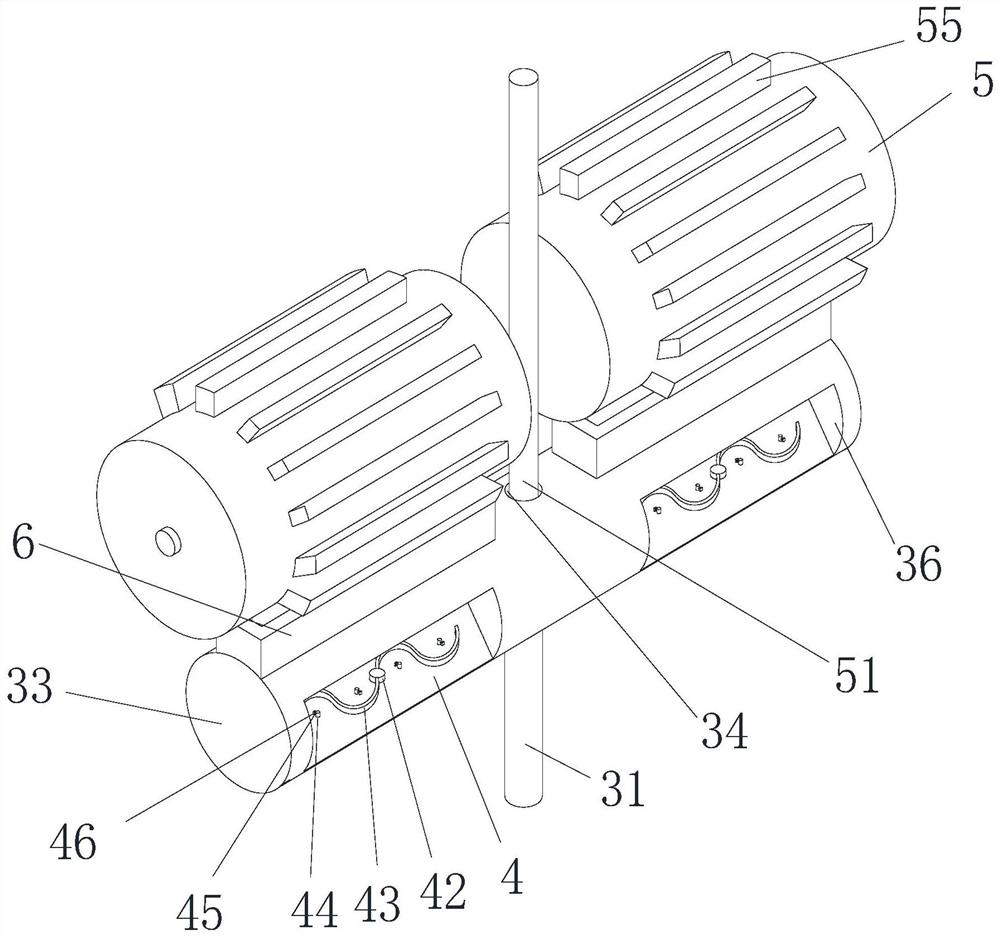

[0032] Embodiment: a kind of chemical product mixing stirring tank, as Figure 1-Figure 6As shown, it includes a mixing tank 1, the mixing tank 1 is a hollow circular column, the outer bottom of the mixing tank 1 is provided with a starting device 2, the starting device 2 includes a base 21, the base 21 is a circular column, The size of the cross-sectional area of the base 21 matches the size of the cross-sectional area of the mixing tank 1, the base 21 is fixedly mounted on the lower end of the mixing tank 1, the upper end of the base 21 is provided with a placement groove 22, and the placement groove 22 is a rectangular groove. The inside of the placement tank 22 is provided with a motor 23, and the motor 23 is a prior art and will not be repeated here. The inner bottom of the mixing bucket 1 is provided with a rotating device 3, and the rotating device 3 includes a rotating column 31, and the rotating column 31 The bottom end and the output shaft of motor 23 are fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com