Petroleum catalytic cracking reaction device

A catalytic cracking and reaction device technology, which is applied in the field of reactors, can solve problems such as slow reaction speed, and achieve the effects of prolonging service life, increasing reaction speed, and facilitating movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

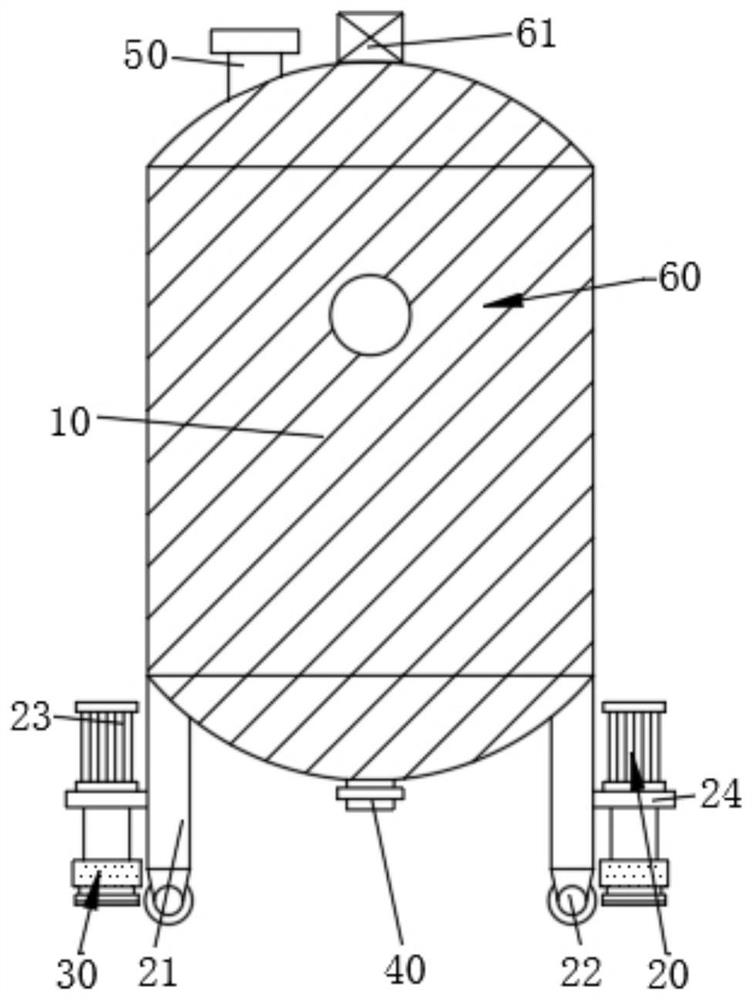

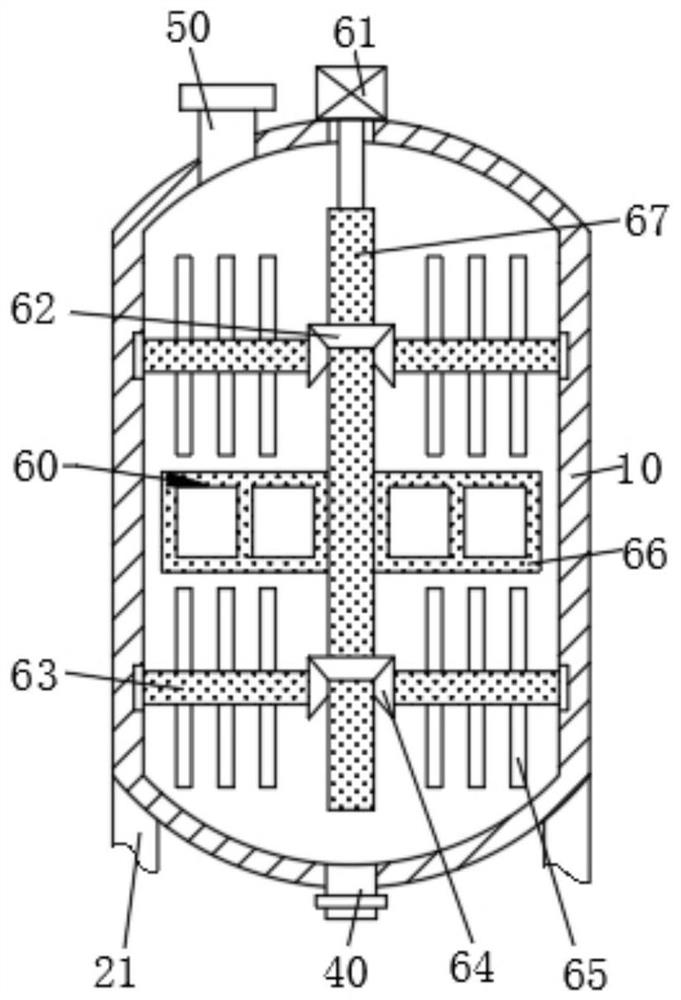

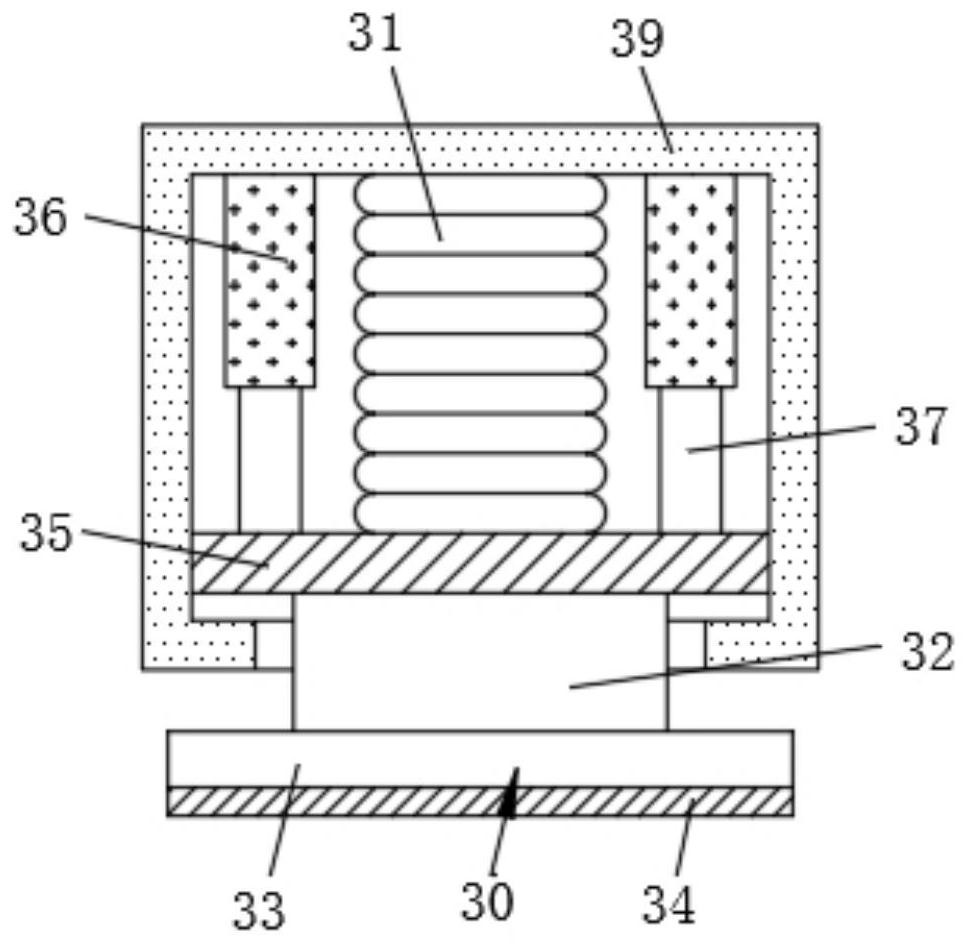

[0018] see Figure 1-Figure 4 , petroleum catalytic cracking reaction device, comprises tank body 10, is provided with stirring mechanism 60 in tank body 10, and the bottom end of tank body 10 is provided with moving mechanism 20, and moving mechanism 20 is provided with buffer mechanism 30, and stirring mechanism 60 comprises motor 61 , the motor 61 is fixedly installed on the tank body 10, the model of the motor 61 is TCB8024 B3, by being provided with the motor 61, it is convenient to drive the first rotating rod 67 to rotate, the rotating shaft end of the motor 61 runs through the tank body 10 and is provided with the first rotating rod 67, by being provided with the first rotating rod 67, it is convenient to drive the first gear 62 and the stirring frame 66 to rotate, the first rotating rod 67 is provided with the first gear 62 and the stirring frame 66, the setting of the first stirring frame 66 plays a role The purpose of horizontally stirring the raw materials is condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com