Method for producing brass alloy small-size wire bar products

A brass alloy, small size technology, used in metal extrusion dies and other directions, to achieve the effect of improving product yield and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for producing brass alloy small-size wire and rod products, comprising the following steps:

[0027] 1) The brass alloy ingot is heated to 600°C in a heating furnace and kept for 5.5 hours to ensure sufficient and uniform heating to obtain hot copper;

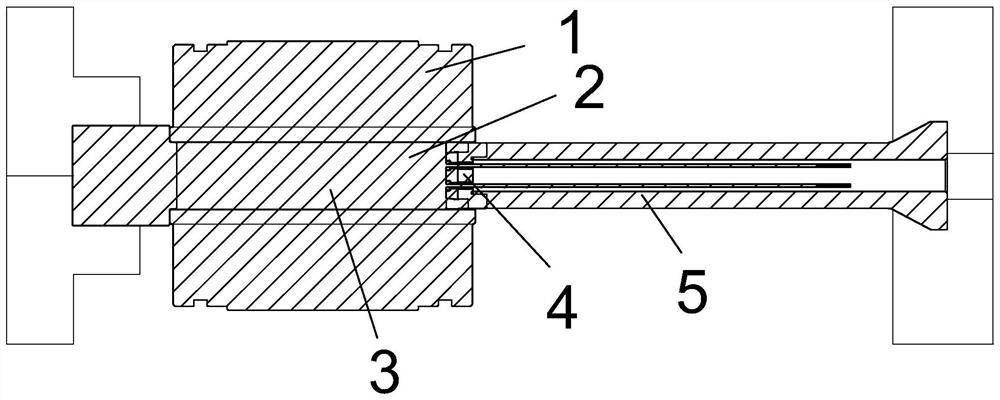

[0028] 2) Preheat the small extrusion mold to 300°C with 4 blowtorches of the same specification equidistantly distributed, keep warm, and then add the hot copper material 3 into the cavity 2 of the small extrusion mold, and the extrusion rod 5 moves to extrude heat The copper material 3 is formed by extruding the hot copper material 3 under the action of the mold core 4 to obtain a copper billet. Preferably, the mold cavity 2 can be made into a truncated cone, the cross-sectional area gradually decreases from the entrance to the exit, and the diameter of the exit hole is 80% of the straight hole of the entrance hole. A choke block can also be arranged between the mold core 4 and the mold cavity 2 to form a 17°...

Embodiment 2

[0031] A method for producing brass alloy small-size wire and rod products, comprising the following steps:

[0032] 1) The brass alloy ingot is heated to 610°C in a heating furnace and kept for 5 hours to ensure sufficient and uniform heating to obtain hot copper;

[0033] 2) Preheat and keep warm the extruding mold with two torches of the same specification equidistantly distributed, the preheating temperature is 250°C, then add the hot copper material 3 into the die cavity 2 of the extruding mold, extrude the rod 5 Extrude the hot copper material 3 by motion, and extrude the hot copper material 3 under the action of the mold core 4 to obtain a copper billet. Preferably, the mold cavity 2 can be made into a truncated cone, the cross-sectional area gradually decreases from the entrance to the exit, and the diameter of the exit hole is 76% of the straight hole of the entrance hole. A choke block can also be arranged between the mold core 4 and the mold cavity 2 to form a 17° ...

Embodiment 3

[0036] A method for producing brass alloy small-size wire and rod products, comprising the following steps:

[0037] 1) The brass alloy ingot is heated to 590°C in a heating furnace and kept for 4 hours to ensure sufficient and uniform heating to obtain hot copper;

[0038] 2) Preheat and keep warm the extruding die by using three torches of the same specification distributed equidistantly. The preheating temperature is 320°C. 5 Extrude the hot copper material 3 by motion, and extrude the hot copper material 3 under the action of the mold core 4 to obtain a copper billet.

[0039] 3) Use conventional stretching methods to apply tension to the extruded copper billet to change its shape and size, so that the shape and size of the stretched copper product meet the required requirements; slowly heat the stretched product to 580°C , heat preservation for 9 hours and air cooling for 2.5 hours, then strip the skin to obtain a small-sized wire and rod brass alloy product with a diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap