Square sleeve machining method

A processing method and a sleeve technology, which are applied in the field of auxiliary processing of iron sheets, can solve the problems of high device cost, complicated bending operation of the device, inconvenient promotion and use, etc., and achieve low structural cost, ensure the quality of hemming processing, and ensure the processing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The square bushing processing method of the present embodiment, the steps are as follows:

[0043] 1. Folding: Select the iron sheet with a specified width, and then start from the front end of the iron sheet, along the length direction of the iron sheet, use the processing device to fold the edge at the same distance, the bending angle is 90°, repeat four times;

[0044] 2. Retain the edge: start from the fourth bend, and cut along the length direction of the iron sheet to the rear end of the iron sheet with a narrow edge of 3cm margin;

[0045] 3. Fixing: make holes on the narrow side, and make holes at the corresponding position of the first end of the iron sheet, and the fasteners pass through the openings of the narrow side and the first end of the iron sheet in turn to fix the narrow side and the first end of the iron sheet.

[0046] The existing directional sleeve adopts a welding process when connecting the iron sheet, which is easy to miss welding, time-consumi...

Embodiment 2

[0048] The square casing processing method of this embodiment is further improved on the basis of Embodiment 1, and the processing device described in step 1 includes:

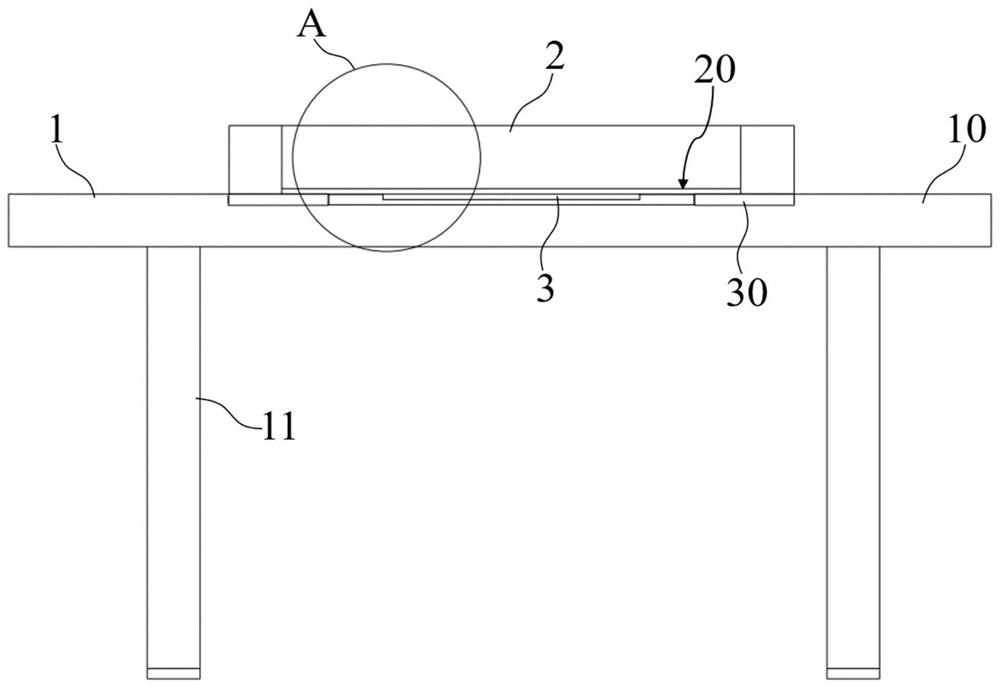

[0049] A workbench 1 is composed of a horizontally arranged platform 10 and support legs 11 fixedly connected to the bottom of the platform 10;

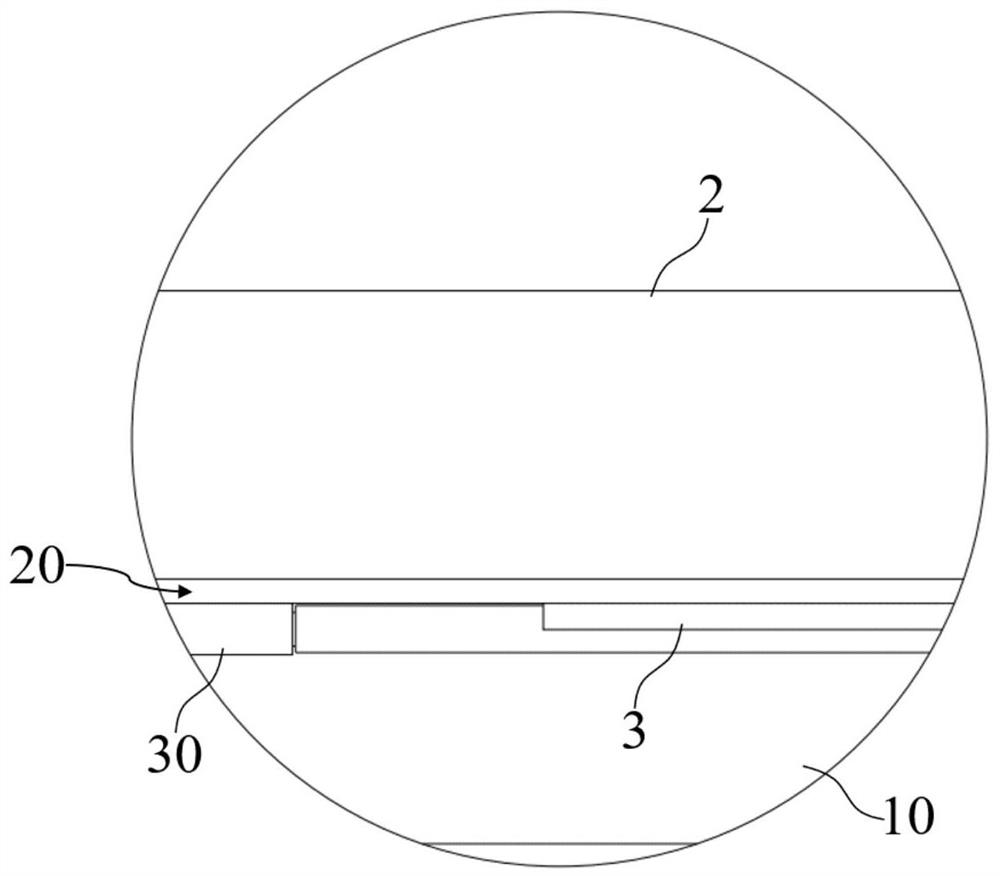

[0050] Platen mechanism 2, which is arranged on the top surface of the front end of the platen 10, between the platen mechanism 2 and the top surface of the platen 10, there is an insertion seam 20 for the iron sheet to be processed to pass through;

[0051] The bent plate portion 3 is a flat plate and is arranged on the front end of the table 10 , and one end of the bent plate 3 is hinged to the front end of the table 10 .

[0052] Although the folding machine dedicated to the current market has high folding efficiency, the price is relatively high, and it is easy to damage the machine when folding the iron sheet above 1.6mm, while the manual processing is inefficie...

Embodiment 3

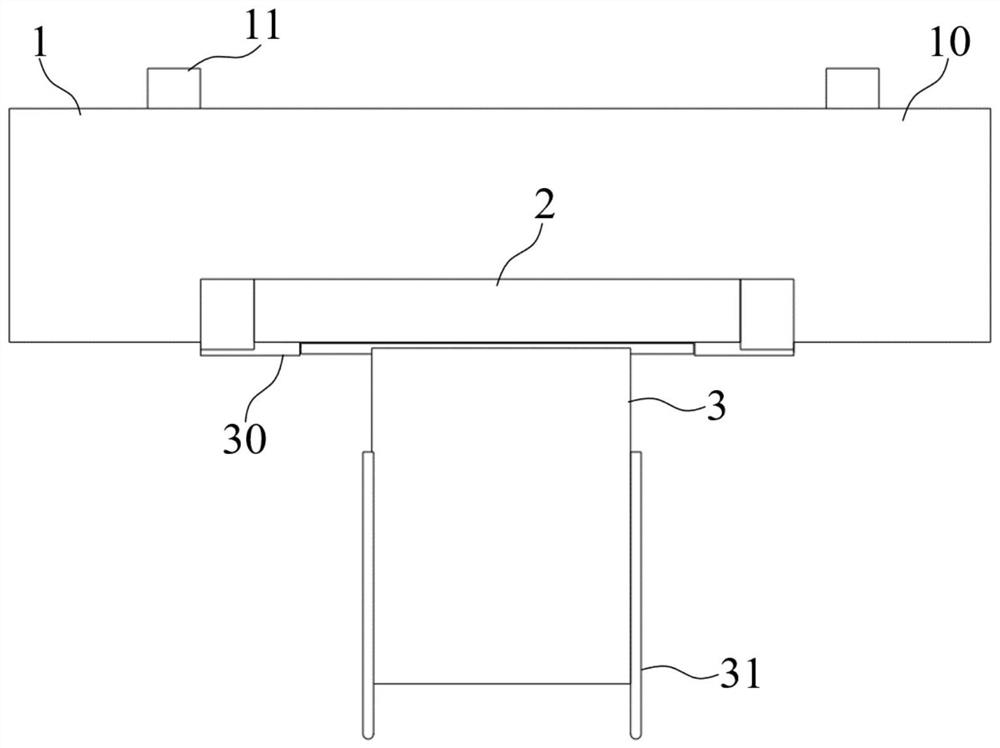

[0056] The square casing processing method of this embodiment is further improved on the basis of Embodiment 2. One end of the bent plate part 3 is hinged to the front end of the platen 10 through the hinge shaft 30, and the other end of the bent plate part 3 is hinged on both sides. An operating handle 31 is fixedly connected.

[0057] Such as figure 2 and image 3 As shown, the hinged shaft 30 includes shaft sleeves located at both ends and a shaft portion located in the middle, the shaft sleeves are fixedly welded on the front end surface of the platen 10, the two ends of the shaft are rotatably connected in the two shaft sleeves, and the bent plate portion 3 One end is fixedly welded to the rotating shaft, thereby forming the hinge between the bent plate portion 3 and the hinge shaft 30 .

[0058] Such as image 3 and Figure 4 As shown, two operating handles 31 are fixedly welded on both sides of the other end of the bending part 3, and the operator can drive the ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com