Double-inclined-hole machining device for numerical control machining center

A processing center and processing device technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of manual cleaning after processing, waste of coolant, inconvenient processing, etc., and achieve power increase and reduction Production cost, effect of slope accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

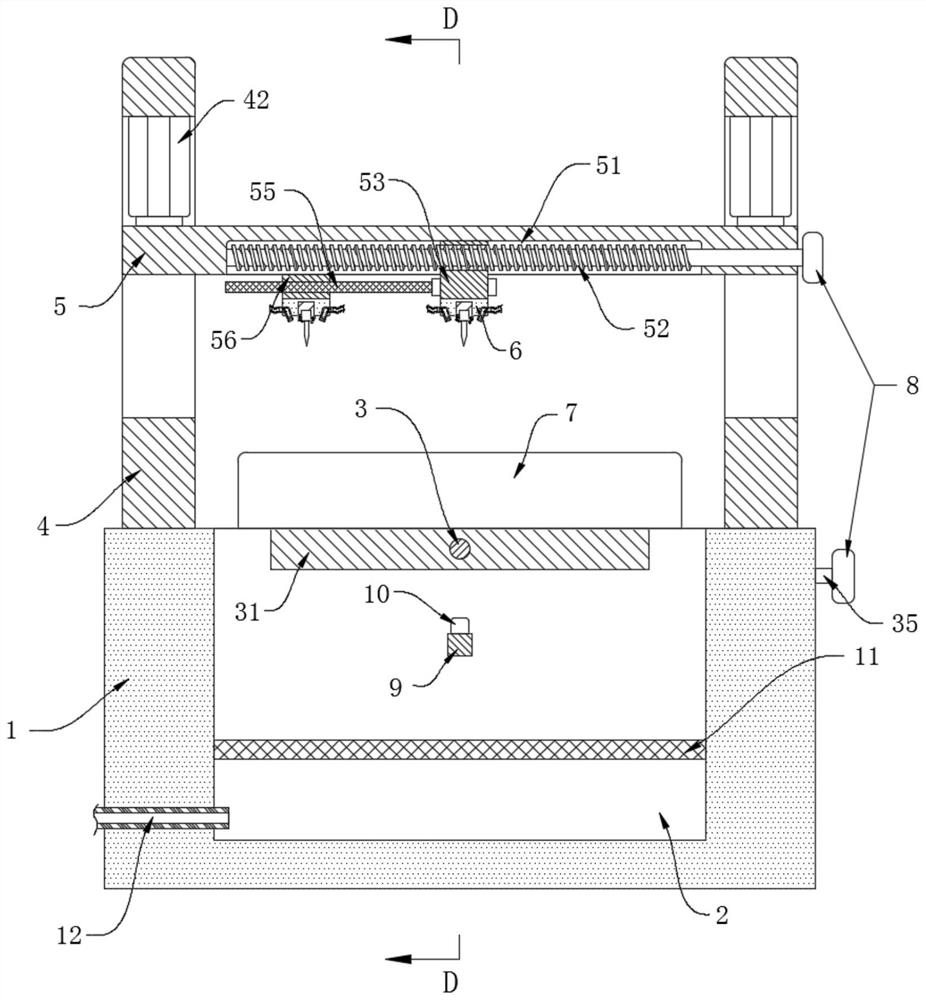

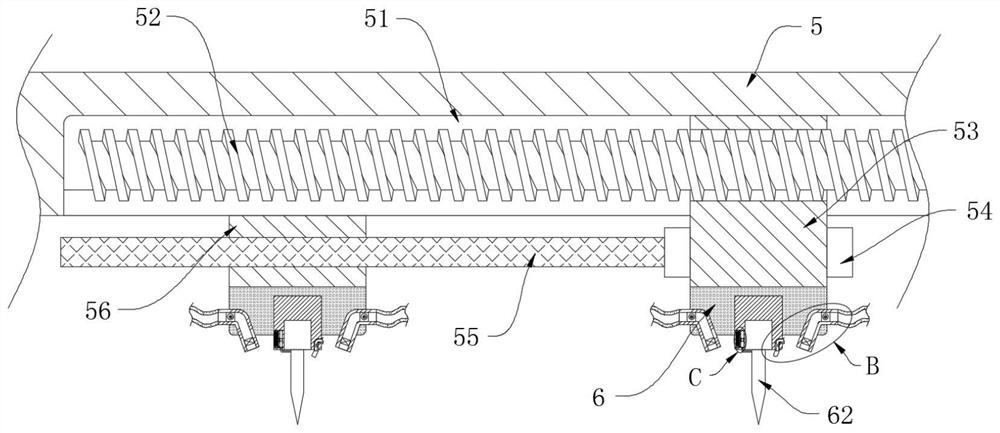

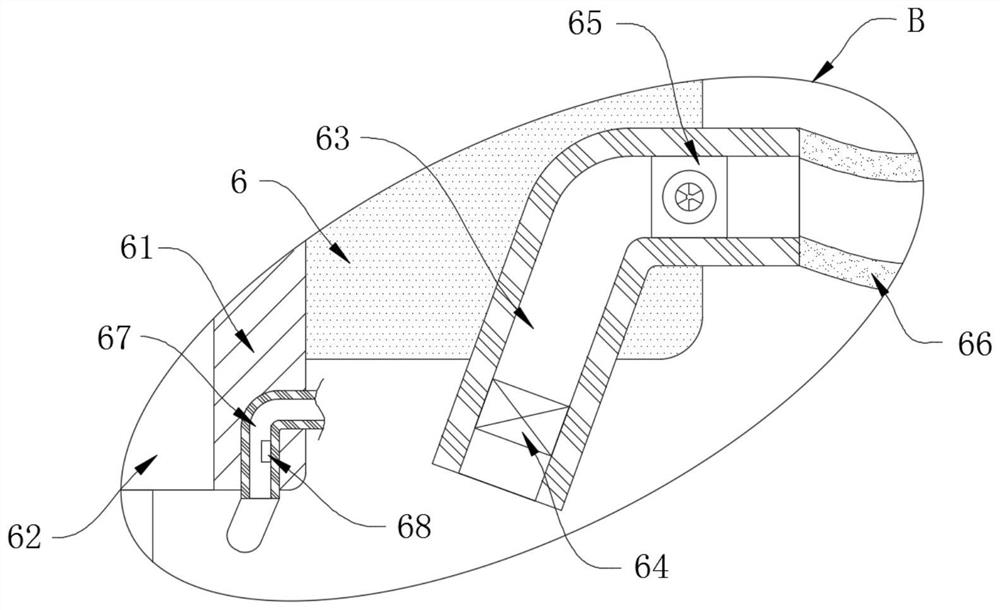

[0030] refer to Figure 1-5 , a double inclined hole processing device for a numerical control machining center, comprising an operating table 1, the operating table 1 is provided with a groove 2, and the upper surface of the operating table 1 is slidingly connected with two columns 4, and the column 4 and the operating table 1 are connected by two The cross-section of the column 4 is back-shaped, the inner top wall of the column 4 is provided with a cylinder 42, and the output end of the cylinder 42 is jointly welded with a crossbeam 5, and the bottom wall of the crossbeam 5 is slidably connected with a first slider 53 through a sliding groove. The crossbeam 5 is connected with a threaded rod 52 through the bearing penetrating rotation, and the threaded rod 52 is threadedly connected with the first slider 53, and the thread lead angle of the threaded rod 52 is smaller than the equivalent friction angle of the helical pair formed by the threaded rod 52 and the first slider 53, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com