Concrete stirring equipment

A kind of mixing equipment and concrete technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, cleaning methods and appliances, etc. It can solve the problems of slow mixing speed, reduced mixing efficiency, and inability to break stones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

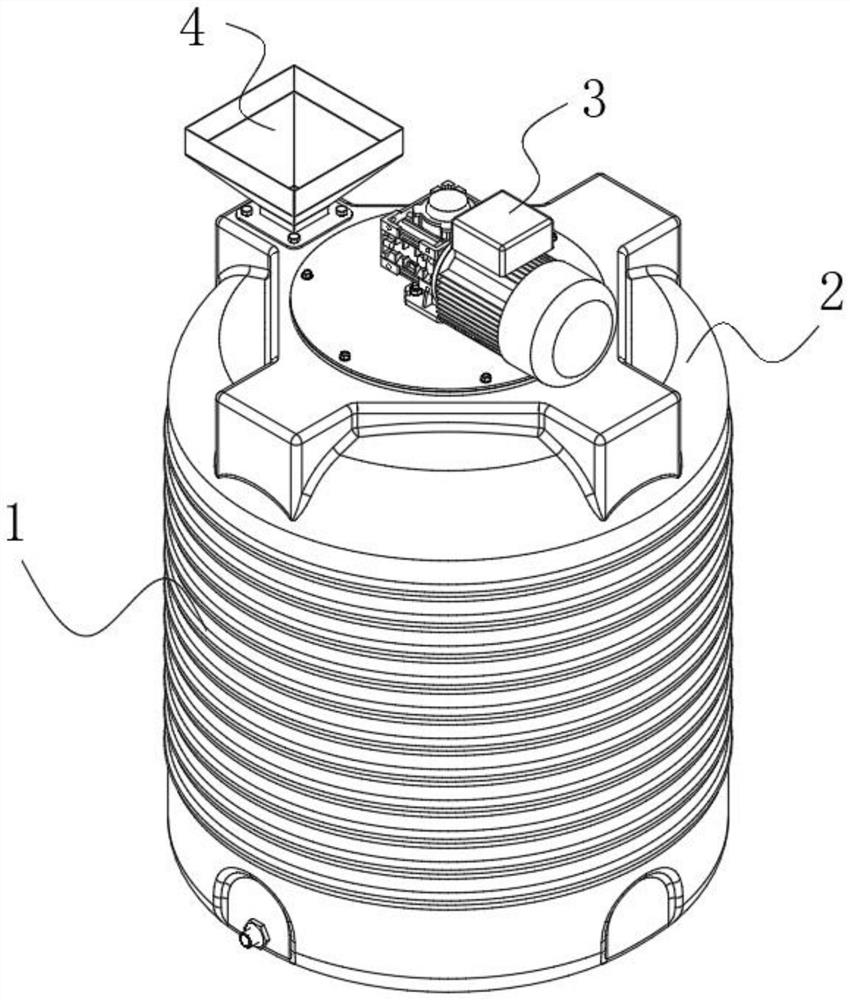

[0019] use Figure 1-Figure 4 A concrete mixing plant according to an embodiment of the present invention will be described as follows.

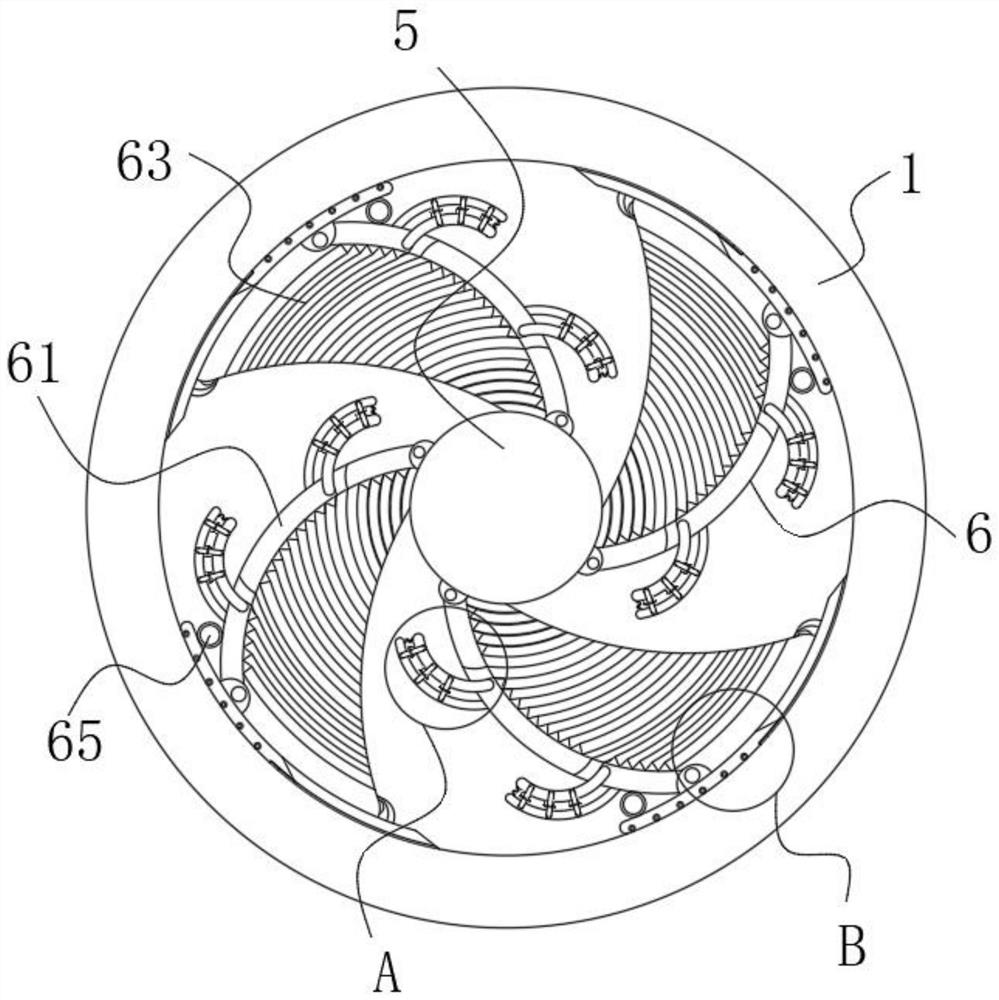

[0020] Such as Figure 1-Figure 4 As shown, a kind of concrete mixing equipment of the present invention comprises a cylinder body 1, a cylinder cover 2, a motor 3, a feed port 4, a rotating rod 5 and a stirring mechanism 6; the cylinder body 1 is cylindrical, and the cylinder The upper end of the body 1 is sealed and fastened with a cylinder cover 2; the upper wall of the left end of the cylinder cover 2 is fixedly connected with a feed port 4, and the outer surface of the upper end of the cylinder cover 2 is fixedly installed with a motor 3; the lower end of the motor 3 A rotating rod 5 is connected to rotate;

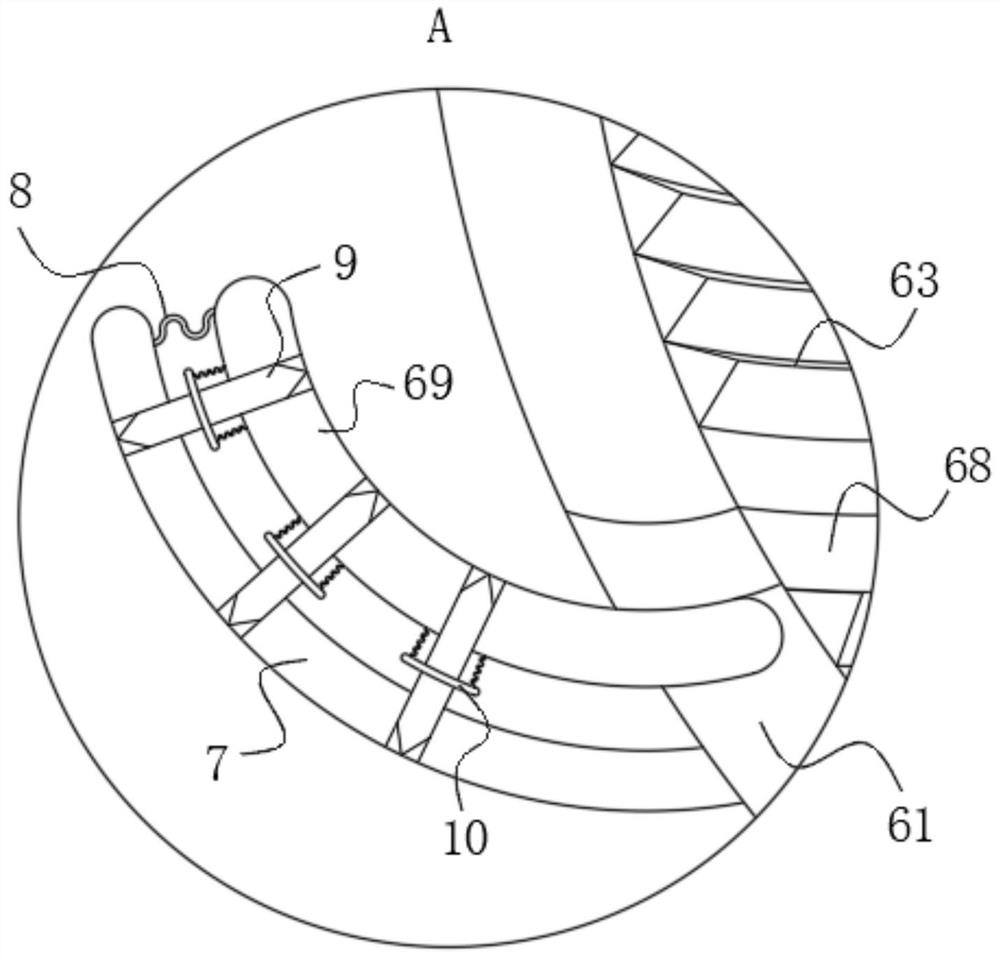

[0021] The stirring mechanism 6 includes a mounting plate 61, a scraper 62, a sawtooth bar 63, a roller 64, a rubber tube 65, an air pressure groove 66, a crushing plate 67, a through hole 68 and a toggle plate 69; the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com