Medical conjoined sleeve wire without tearing traces and preparation method of medical conjoined sleeve wire

A sleeve and one-piece technology, applied in the field of medical devices, can solve problems such as scratches, glue residue, and protrusions, and achieve the effect of improving safety performance and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

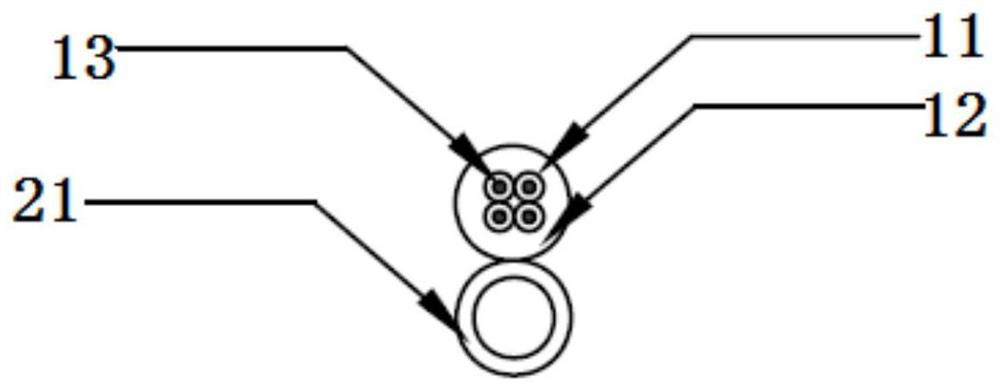

[0034] A method for preparing a tear-free medical conjoined sleeve wire, comprising the following steps:

[0035] 1) Put the raw materials used in the sleeve 2 and the wire tube 1 into two extruders respectively, heat at 170°C for 8 minutes to melt and extrude, and then pass through the mold to form the sleeve 2 and the wire tube 1 respectively;

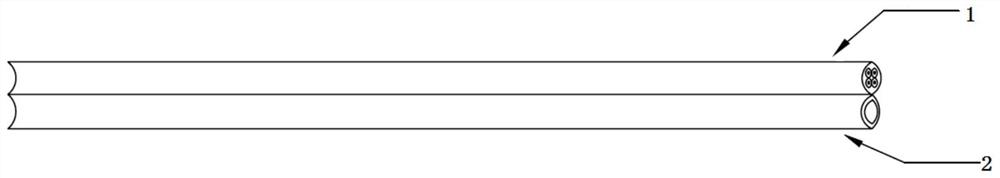

[0036] 2) At the moment when the sleeve 2 and the wire tube 1 obtained in step 1) leave the mold, they enter the infrared heater, and after contacting the surface of the sleeve 2 and the wire tube 1, they are heated at a constant temperature of 180°C. The surfaces of casing 2 and wire pipe 1 are evenly heated to make their skins self-adhesive, and then cooled by 8°C cooling water for 30 seconds to be shaped, the following is obtained: figure 1 The tear-free medical one-piece sleeve wire shown.

[0037] Wherein, in step 1), the raw materials used for the casing 2 and the wire tube 1 are polyvinyl chloride (PVC) free of phthalate. Ph...

Embodiment 2

[0042] A method for preparing a tear-free medical conjoined sleeve wire, comprising the following steps:

[0043] 1) Put the raw materials used in the sleeve 2 and the wire tube 1 into the extruder respectively, heat and melt at 225°C for 5 minutes to extrude, and then pass through the mold to form the sleeve 2 and the wire tube 1 respectively;

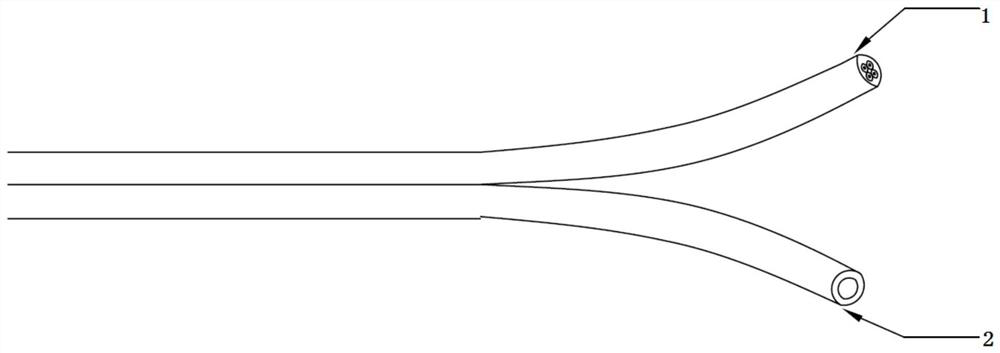

[0044] 2) At the moment when the casing 2 and the wire tube 1 obtained in step 1) leave the mold, they enter the infrared heater, and after contacting the surface of the sleeve 2 and the wire tube 1, they are heated at a constant temperature of 250°C. The surfaces of casing 2 and wire pipe 1 are evenly heated to make their skins self-adhesive, and then cooled by 30°C cooling water for 5 seconds to be shaped, the following is obtained: Figure 4 The tear-free medical one-piece sleeve wire shown.

[0045]Wherein, in step 1), the raw materials used for the sleeve 2 and the wire tube 1 are both medical thermoplastic elastomers (TPE). Th...

Embodiment 3

[0049] A method for preparing a tear-free medical conjoined sleeve wire, comprising the following steps:

[0050] 1) Put the raw materials used in the sleeve 2 and the wire tube 1 into two extruders respectively, heat at 260°C for 10 minutes to melt and extrude, and then pass through the mold to form the sleeve 2 and the wire tube 1 respectively;

[0051] 2) At the moment when the sleeve 2 and the wire tube 1 obtained in step 1) leave the mold, they enter the infrared heater, and after contacting the surface of the sleeve 2 and the wire tube 1, they are heated at a constant temperature of 250°C. The surface of the middle casing 2 and the electric wire tube 1 is evenly heated to make the skins of the two self-adhesive, and then cooled by 30°C cooling water for 5s to 30°C to be shaped, the following is obtained: figure 1 The tear-free medical one-piece sleeve wire shown.

[0052] Wherein, in step 1), the raw materials used for the casing 2 and the wire tube 1 are polyvinyl chlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com