Embroidery machine driver

A driver and embroidery machine technology, which is applied in the field of embroidery machine drivers and embroidery machines, can solve problems such as troublesome and difficult adjustment of driving stroke, and achieve the effects of simple adjustment, avoiding scale misreading, and easy inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

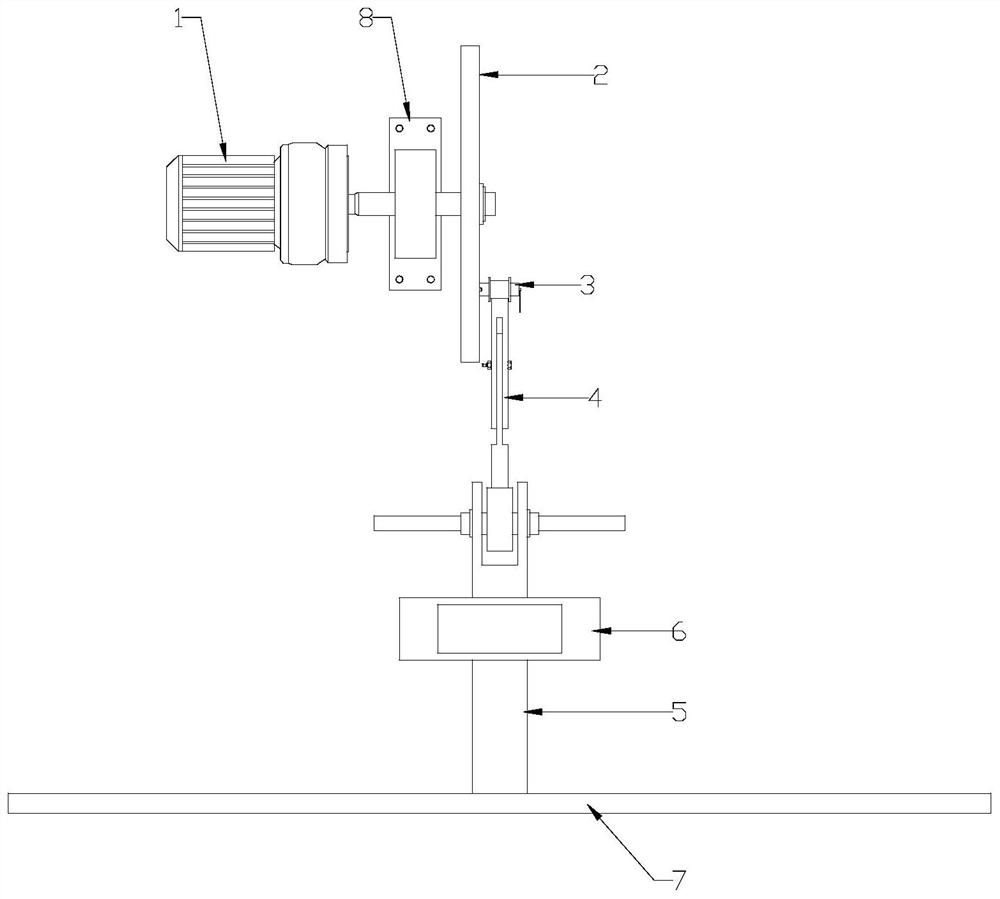

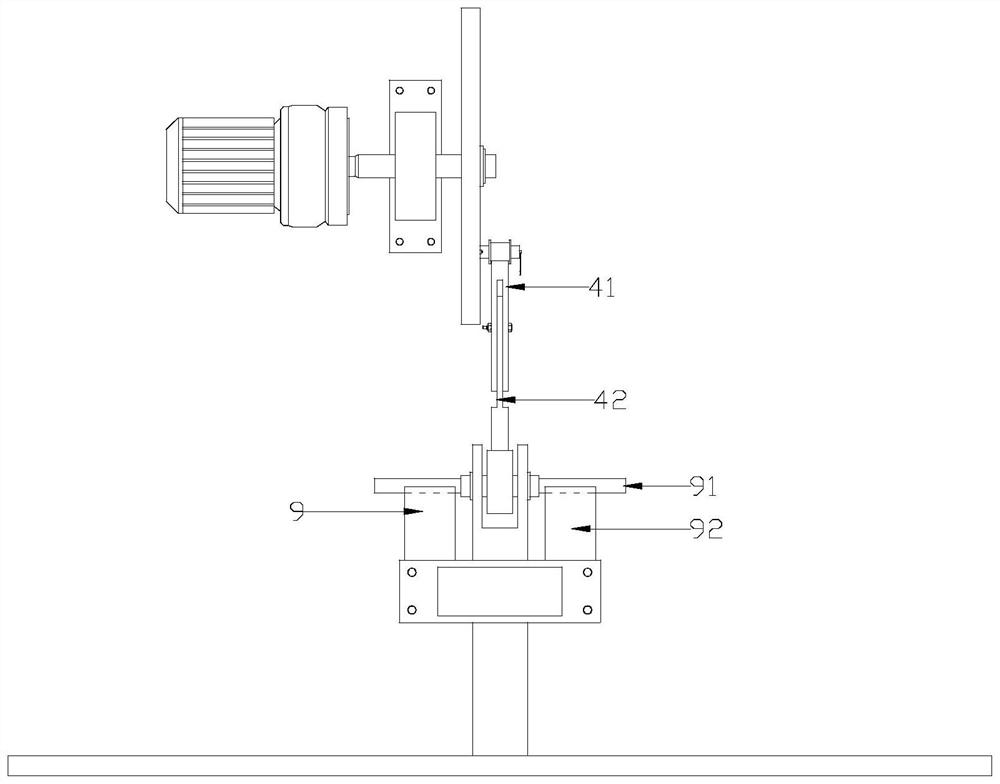

[0022] refer to Figure 1 to Figure 5 , an embroidery machine driver of the present invention, comprising a motor 1, a runner 2, a handle 3, a rocker 4, a slide bar 5, a guide sleeve 6 and an end plate 7, one side of the runner 2 is concentrically fixed on the motor 1 The end of the output shaft, the rotating handle 3 is eccentrically and detachably installed on the other side of the rotating wheel 2, one end of the rocker 4 is sleeved outside the rotating handle 3 and the other end is hinged with one end of the sliding rod 5 , the other end of the slide bar 5 is connected to the end plate 7 after passing through the guide sleeve 6, and the motor 1 and the guide sleeve 6 are respectively fixed on the embroidery machine.

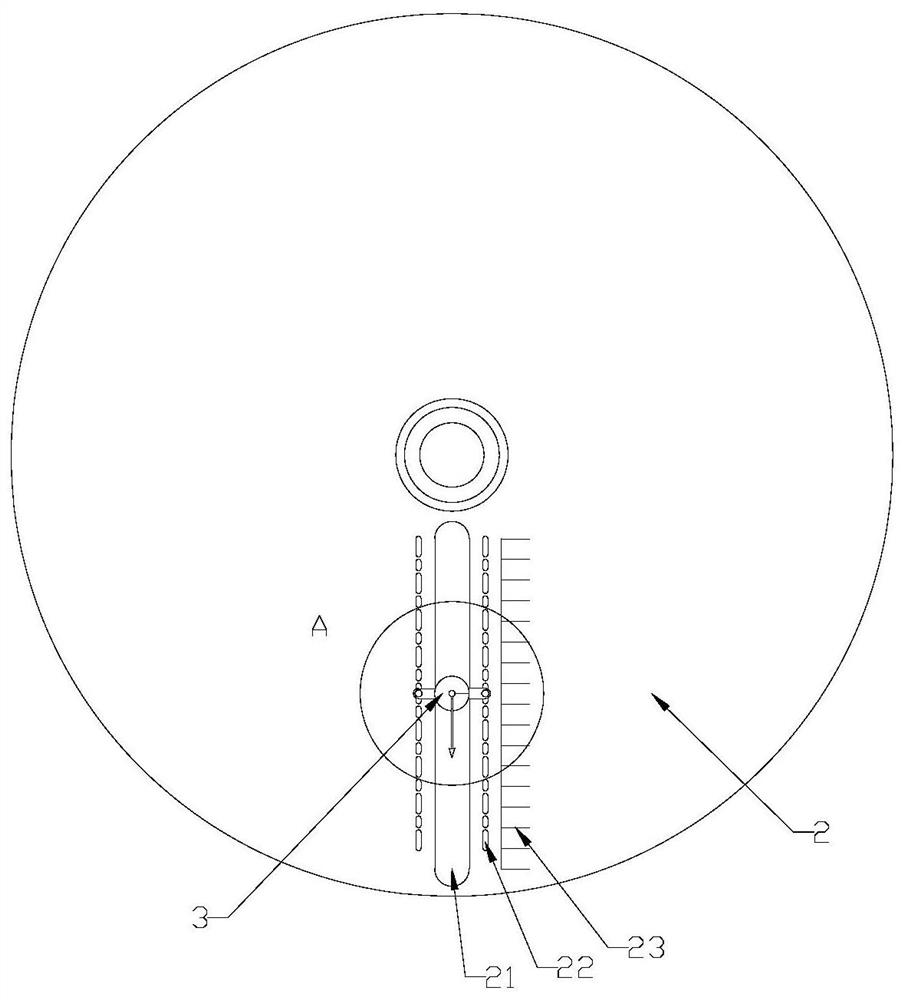

[0023] The side of the runner 2 away from the motor 1 is provided with a chute 21, the rotating handle 3 is slidably connected in the chute 21 and can approach or move away from the center of rotation of the runner 2 along the chute 21, the runner 2 2 The si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com