Pervious concrete municipal road construction method

A technology of permeable concrete and municipal roads, which is applied in the field of permeable concrete municipal road construction, and can solve problems such as the influence of construction devices, shaking and skewing in water tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

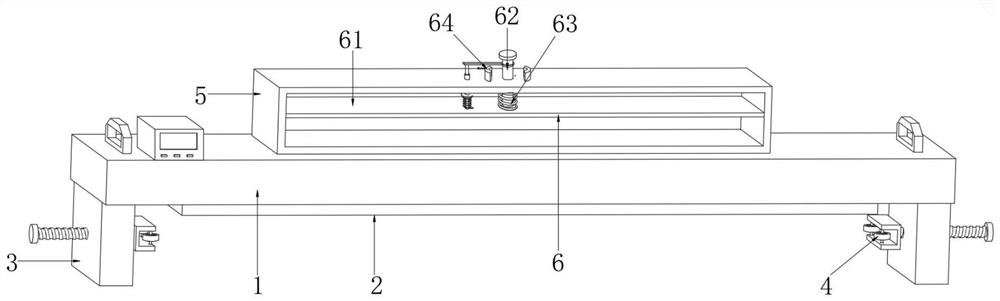

[0025] The present invention provides a technical solution: a water-water construction device, please refer to figure 1 , Including mounting frame 1, splay plate 2, mounting plate 3 and mobile device 4;

[0026] See figure 1 The splay plate 2 is mounted on the bottom central outer wall of the mounting frame 1, the mounting plate 3 has the same structure, and the two sets of mounting plates 3 are mounted on the outer wall of the bottom left and right side of the mounting frame 1, the mobile device 4 has the same structure. The two groups, the two sets of mounting plates 3 are screwed with a threaded rod, and the two sets of threaded rods are connected to each other from each other, and the mobile device 4 includes mounting. The frame, the guide wheel and the drive motor are mounted on the mounting frame and the drive motor is mounted on the mounting frame, and the output shaft of the drive motor is connected to the guide wheel, and the drive motor is rotated with the guide wheel, s...

Embodiment 2

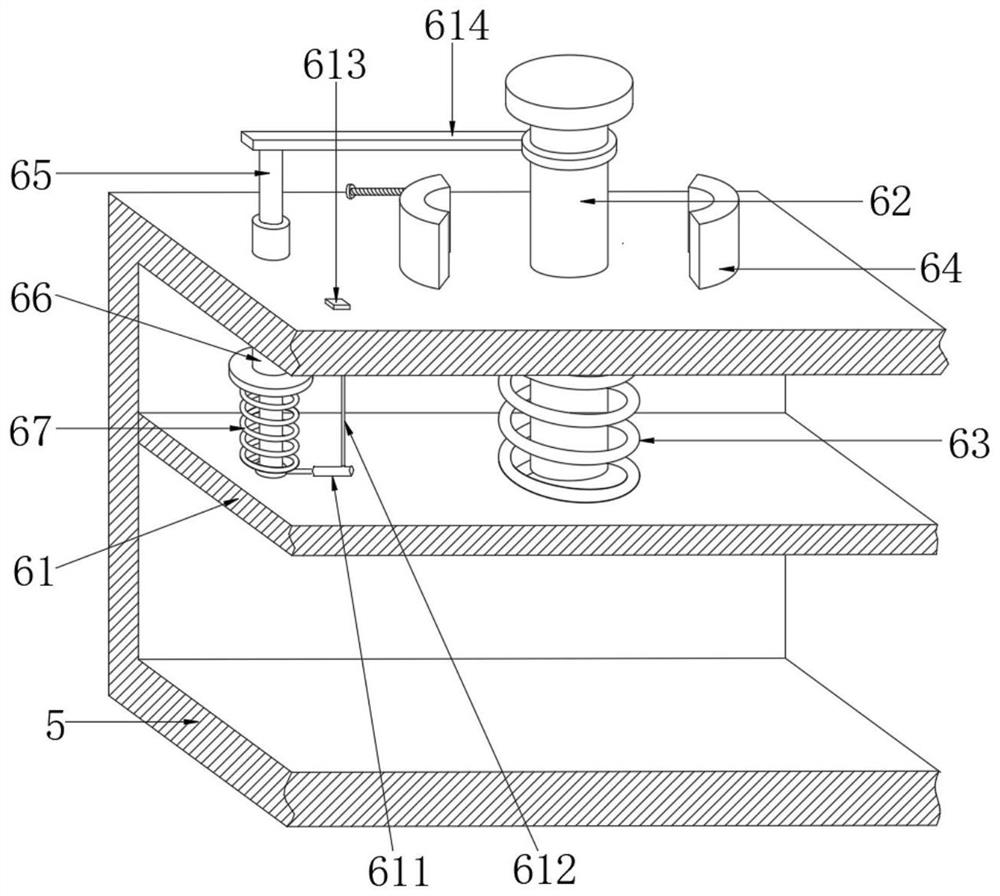

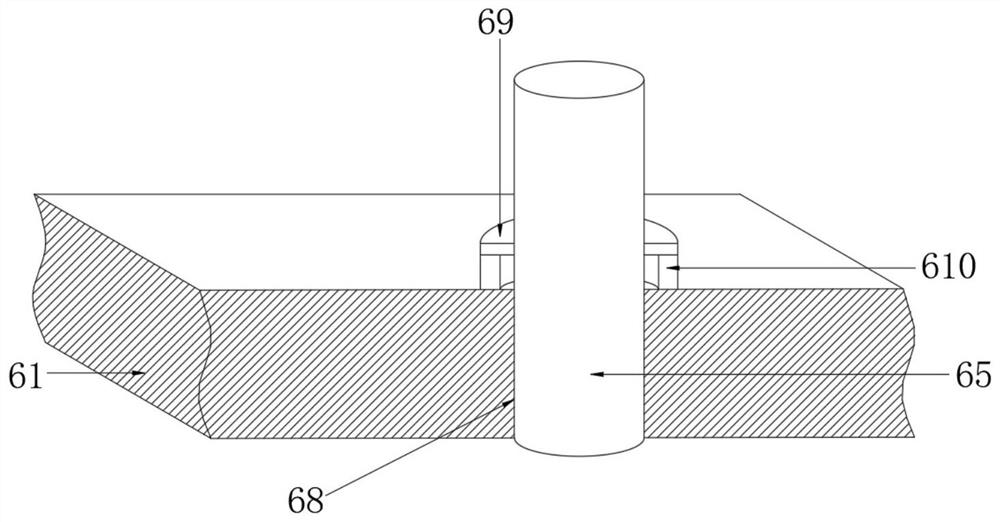

[0030] See figure 2 and image 3 On the basis of Example 1, the outer wall of the top of the pressure plate 61 opens an insertion hole 68, and the outer wall of the top of the water storage tank 5 is opened, and the inner cavity of the open hole is inserted with a plug 65, and the bottom end of the plug 65 extends to the jack 68. In the inner cavity, the outer wall of the plug 65 is attached to the support spring 67, the outer wall of the plug 65 is attached to the mounting sleeve 66, and the mounting sleeve 66 is opened through the opening, and the outer wall of the mounting sleeve 66 and the inner wall of the opening is provided. The thread is threaded, and the support spring 67 is respectively connected to the outer wall of the plug 65, and the bottom outer wall of the mounting sleeve 66 can be removed from the inner cavity of the jack 68 for opening the socket 68, so that the pressure plate 61 is downward. When in contact with the water surface, the air between the water surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com