Prefabricated column and cast-in-place concrete structure sleeve inverted insertion type secondary grouting construction method

A secondary grouting and construction method technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems affecting the fullness of prefabricated construction grouting, affecting the qualified rate of structural connection construction, unfavorable air discharge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

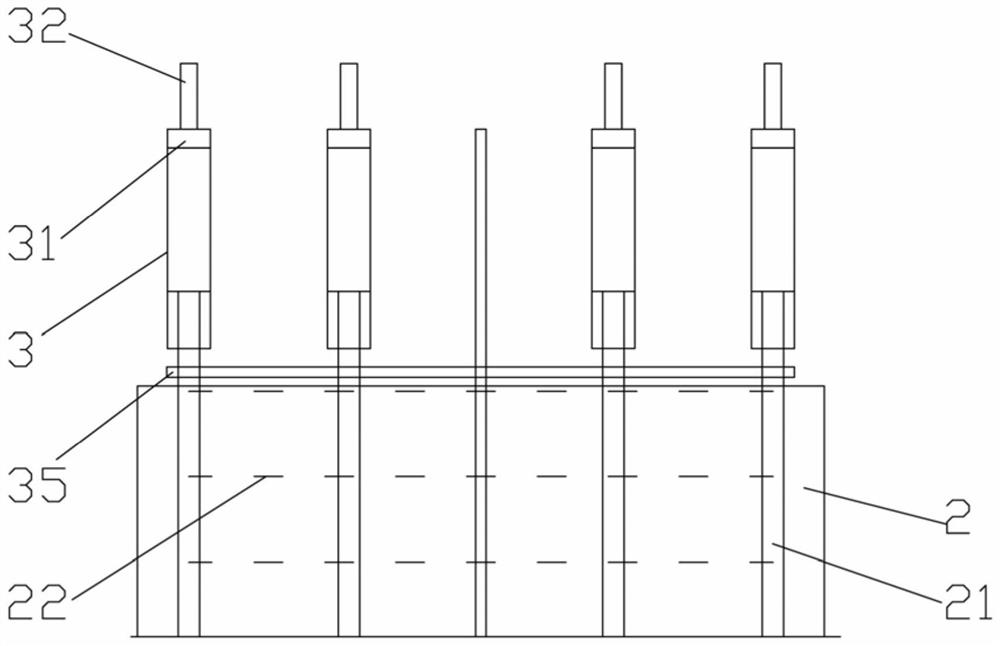

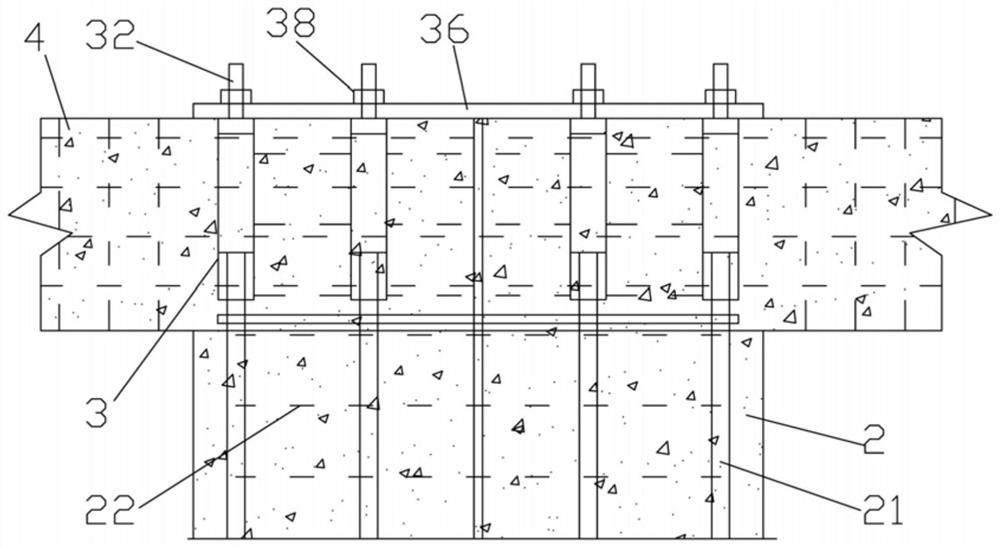

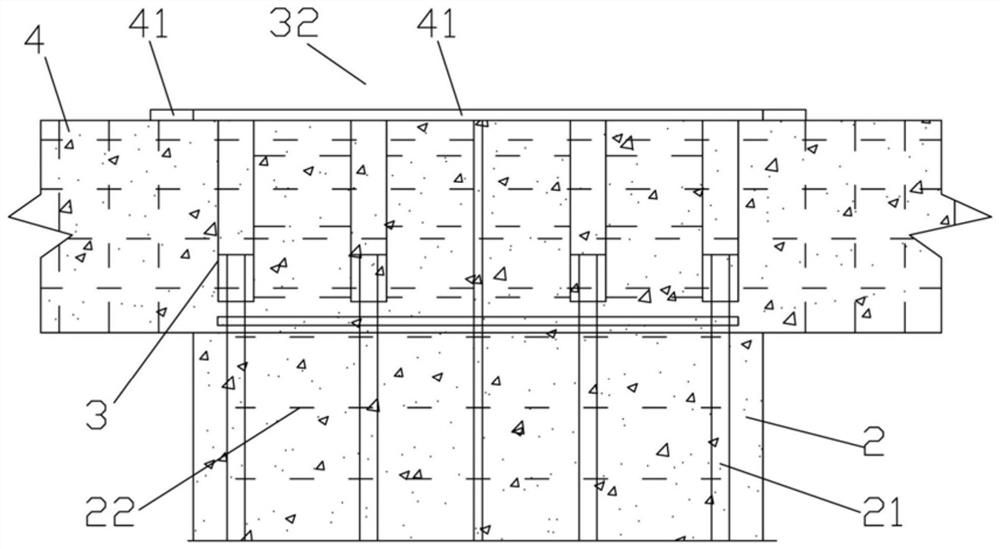

[0036] refer to Figure 1 to Figure 11 , a prefabricated column and cast-in-situ concrete structure sleeve inverted secondary grouting construction method, which includes the following steps:

[0037] Step 1, construction of cast-in-place concrete structure, please refer to figure 1 and figure 2 ;

[0038] The cast-in-place concrete structure includes a cast-in-place pile 2 with a reinforced concrete structure and a cast-in-place floor 4 positioned at the top of the cast-in-place pile 2; a plurality of cast-in-place pile reinforcements 21 and A number of cast-in-place pile stirrups 22 arranged horizontally, the inner top of the cast-in-place pile 2 is located at the upper end of the cast-in-place pile column reinforcement 21 and a sleeve 3 is installed. flat; the cast-in-place floor 4 has horizontally laid floor reinforcement; in this embodiment, the cast-in-place pile 2 is specifically a basement structural column, and the cast-in-place floor 4 is specifically the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com