Retreating type coal seam hydraulic broaching, cave-building and permeability-increasing device and permeability-increasing method

A cave-making and hydraulic technology, applied in drilling equipment and methods, safety devices, earthwork drilling and other directions, can solve the problems of poor gas drainage effect, long drainage time, low gas drainage efficiency, etc. The effect of gas drainage working time, improving gas drainage efficiency, and increasing coal permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention, that is, the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments.

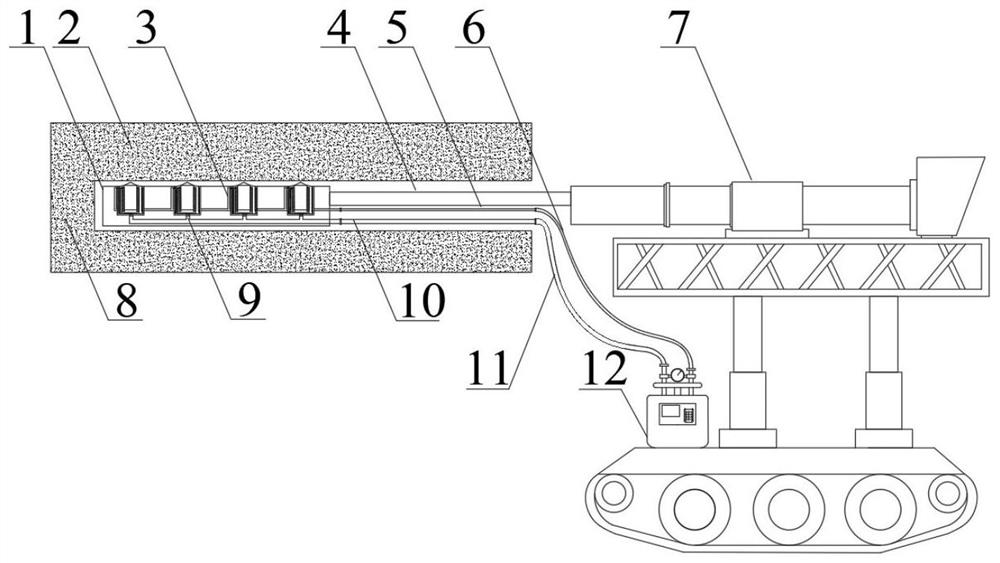

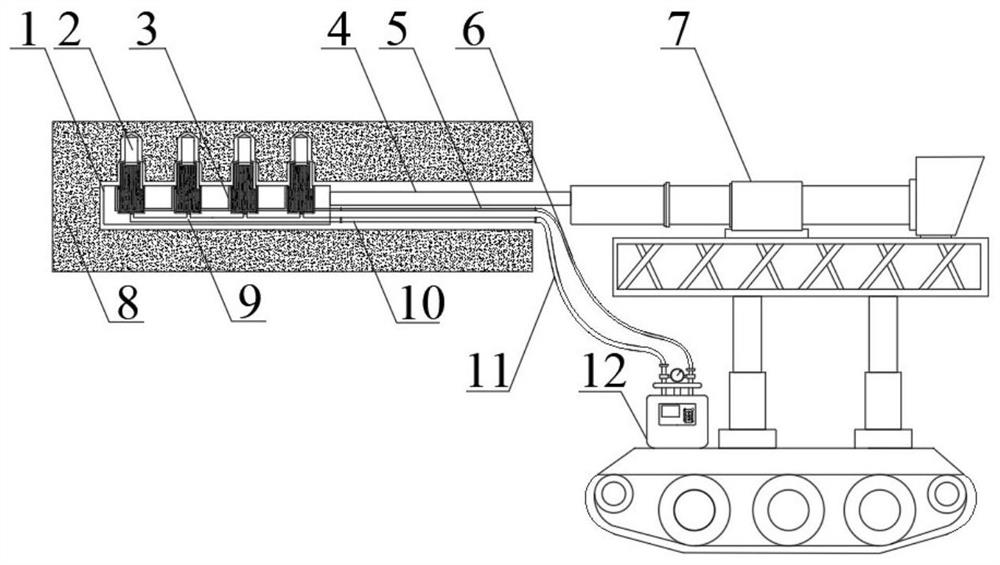

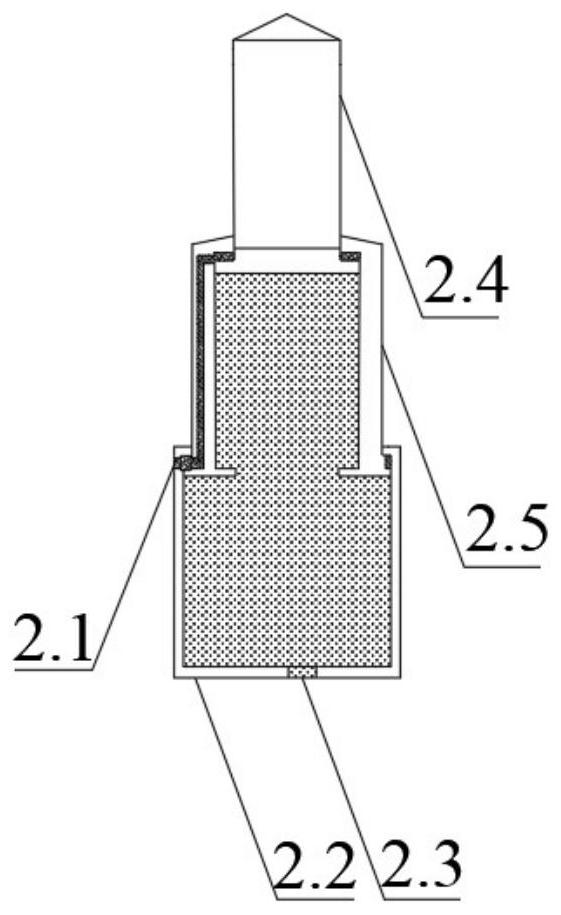

[0026] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention provides a retreat type coal seam hydraulic reaming cavitation anti-reflection device, comprising a hydraulic reaming cavitation rod 1, a reaming ejector rod 2, a hydraulic oil pipeline I3 in the cavity, a connecting rod 4, a hydraulic oil Connecting pipe I5, high-pressure hose I6, angle controller 7, hydraulic oil pipeline II9 in the cavity, hydraulic oil connecting pipe II10, high-press...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap