Construction method for blocking super-large-diameter tunnel under water-rich stratum

A technology for super-large diameter, water-rich strata, which is used in earth-moving drilling, infrastructure engineering, mining equipment, etc., can solve problems such as difficulty in completing plugging, and achieve the effects of reducing potential safety hazards, saving construction costs, and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

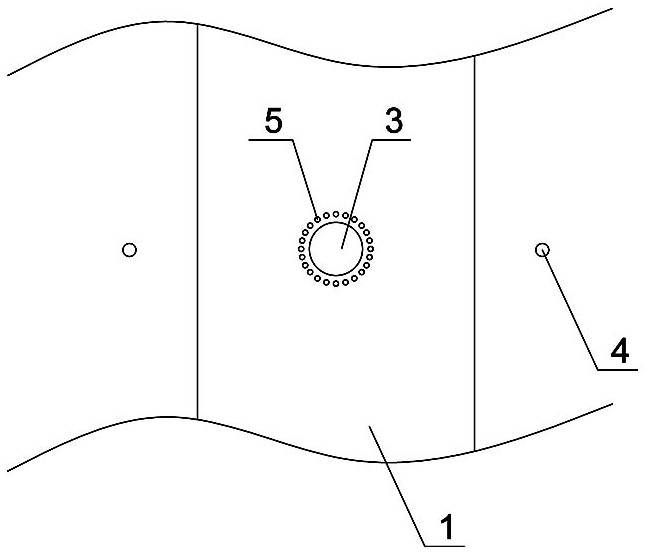

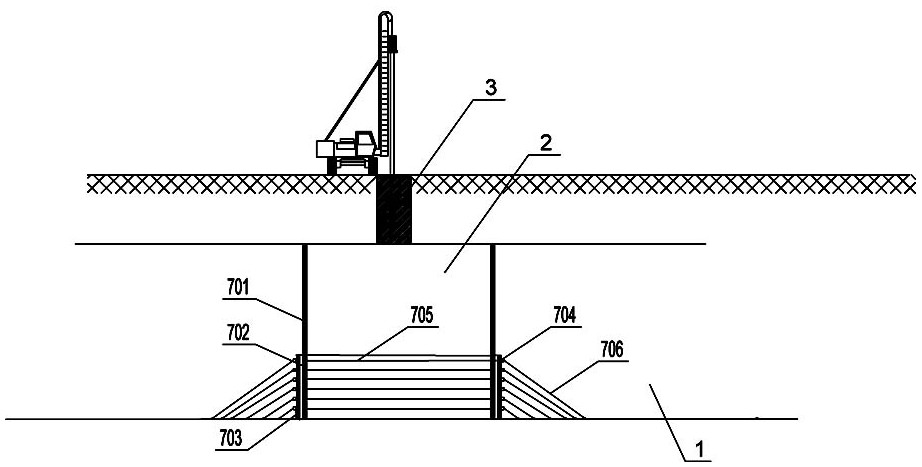

[0026] Such as figure 1 As shown, when a certain station of Metro Line 2 in a certain city is being constructed, the tunnel 1 will pass through first, and then the main body of the station will be constructed. The underground water level m of the above-mentioned station location is about 7 meters below the ground, while the shield segment of tunnel 1 has a diameter of 6.25 m, a wall thickness of 35 cm, and a buried depth of about 9 meters below the ground, and the shield segment and the station enclosure Conflicting pile positions. If the tunnel 1 is not blocked, a large amount of drilling mud will be lost during the construction of the surrounding piles of the station, so that the concrete of the surrounding piles cannot be poured to the design elevation. At the same time, a large amount of sand and groundwater will flow into the tunnel 1, affecting the tunnel. 1 for later use. Therefore, the shield tunnel 1 needs to be sealed before constructing the station enclosure piles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com