Integrated packaging type self-cooling circulating mechanical seal

A mechanical seal and self-cooling technology, which is applied in the direction of mechanical equipment, non-variable pumps, machines/engines, etc., can solve the problems of many types of mechanical seals, high requirements for corrosion resistance, and limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

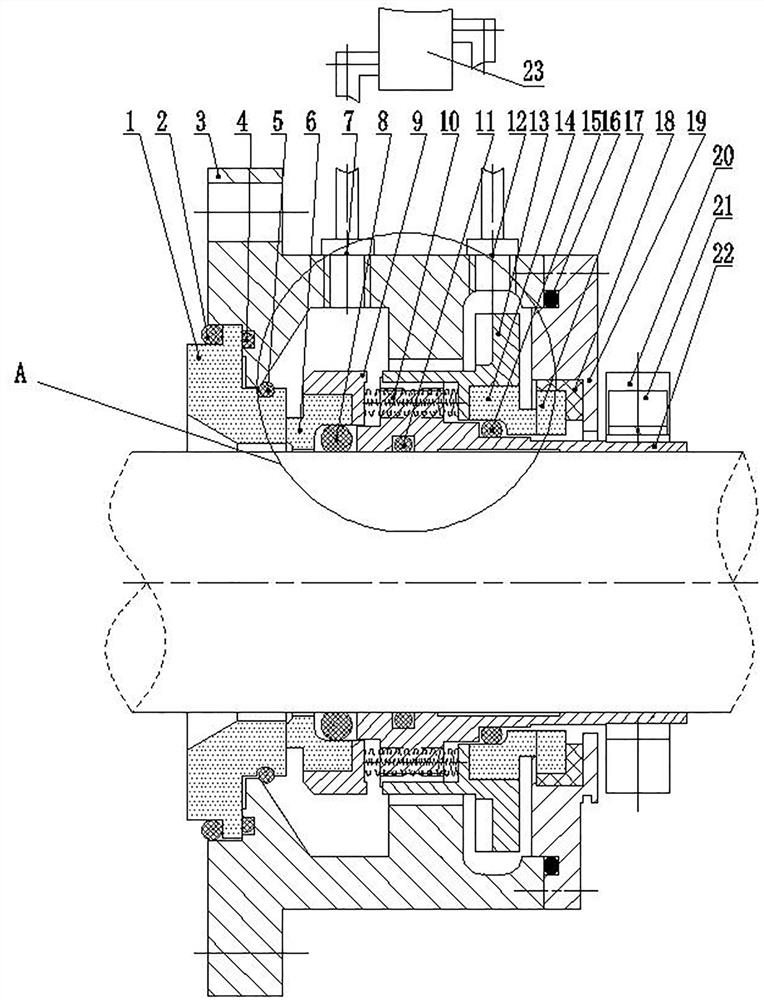

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

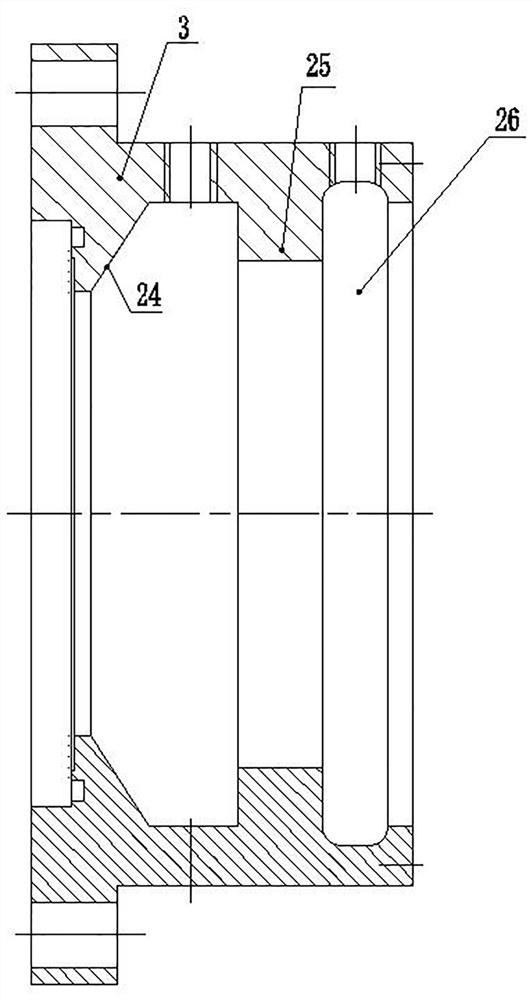

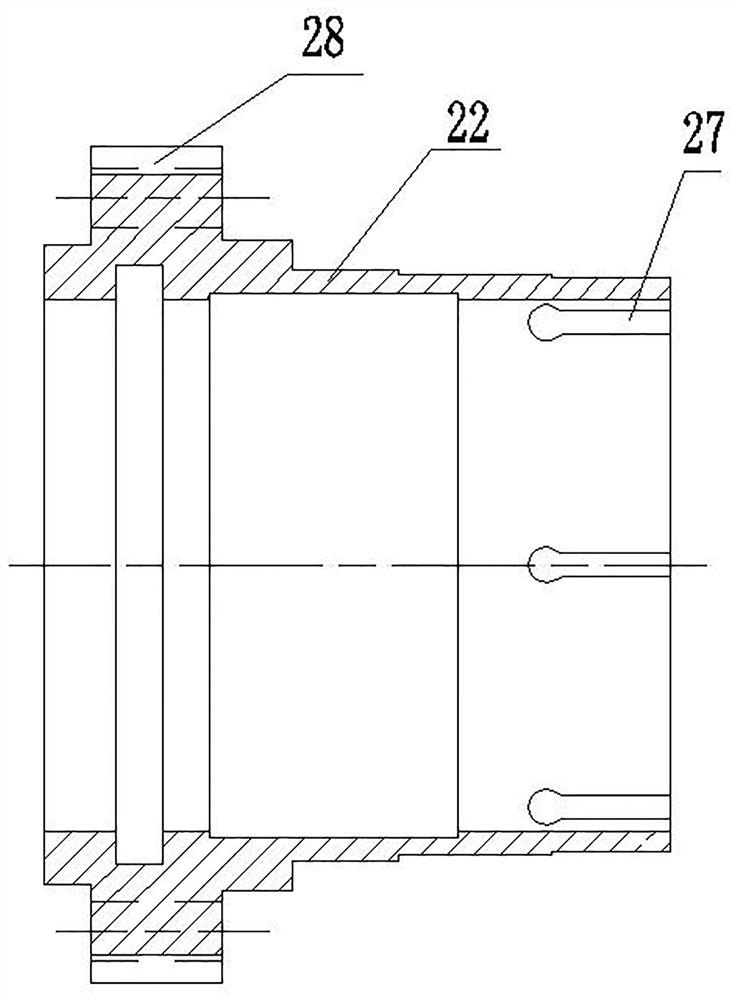

[0033] Such as Figure 1-7 As shown, a packaged self-cooling cycle mechanical seal, a packaged self-cooling cycle mechanical seal, includes a mechanical seal cover 3, a cooling water inlet 7 and a cooling water outlet 12 are opened on the mechanical seal cover 3, and the mechanical seal One side of the cover 3 is equipped with the first static ring 1, and the other side of the mechanical seal cover 3 is fastened with the second static ring seat 19 by bolts, and the second static ring seat 19 and the mechanical seal cover 3 are equipped with the second static ring seat 19. Two static ring O type rings 16 are used for sealing cooling water. The mechanical seal cover 3 is equipped with an elastic limit assembly, and one side of the first static ring 1 is equipped with an anti-loosening O-ring 5 , and an anti-loosening inclined surface 24 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com