Pipeline inspection robot carrying platform

A technology for inspection robots and platforms, applied in special pipes, pipe components, mechanical equipment, etc., can solve problems such as steep steps, inability of workers to go down, and inappropriate workers, and achieve the effect of delaying the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

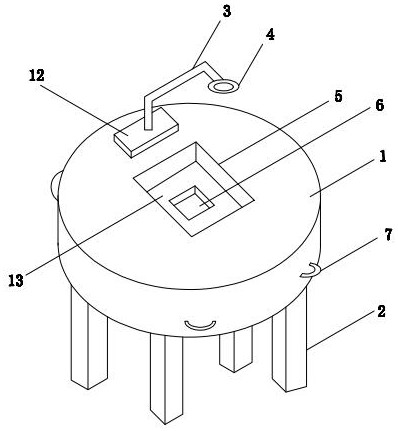

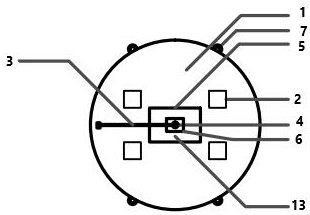

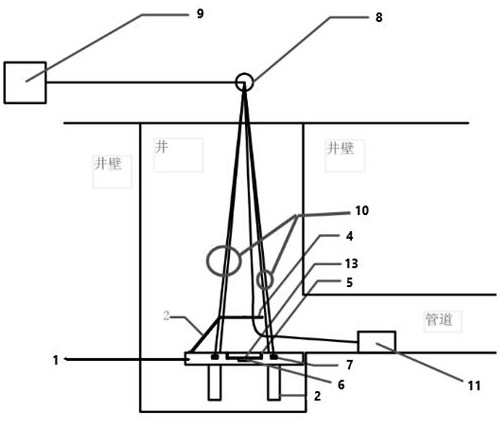

[0015] see Figure 1-Figure 3 As shown, the technical solution adopted in this embodiment is:

[0016] It includes platform panel 1, automatic lifting foot 2, support cantilever 3, cable pulley 4, panel slot 5, pipeline inspection robot fixing slot 6, cable fixed end 7, wire take-up 8, platform control system and pipeline Inspection robot rope reel 9, platform cable 10, pipeline inspection robot 11, fixed seat 12, liftable panel 13; the lower part of the platform panel 1 is provided with an automatic lifting foot 2, and the upper surface of the platform panel 1 is provided with a support cantilever 3. A cable pulley 4 is installed at the end of the support cantilever 3, and a panel slot 5 is set in the middle of the upper surface of the platform panel 1, and a fixed slot 6 for a pipeline inspection robot is opened in the middle of the panel slot 5, and a plurality of slots are provided on the side of the platform panel 7. The cable fixed end 7; the platform cable 10 is releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com