A high-precision sensor device for smart factories

A high-precision sensing and factory technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as inaccurate recognition, reduced resolution of small objects, dead angles of scanning cameras, etc., to achieve high scanning resolution, The effect of good accuracy and comprehensive accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

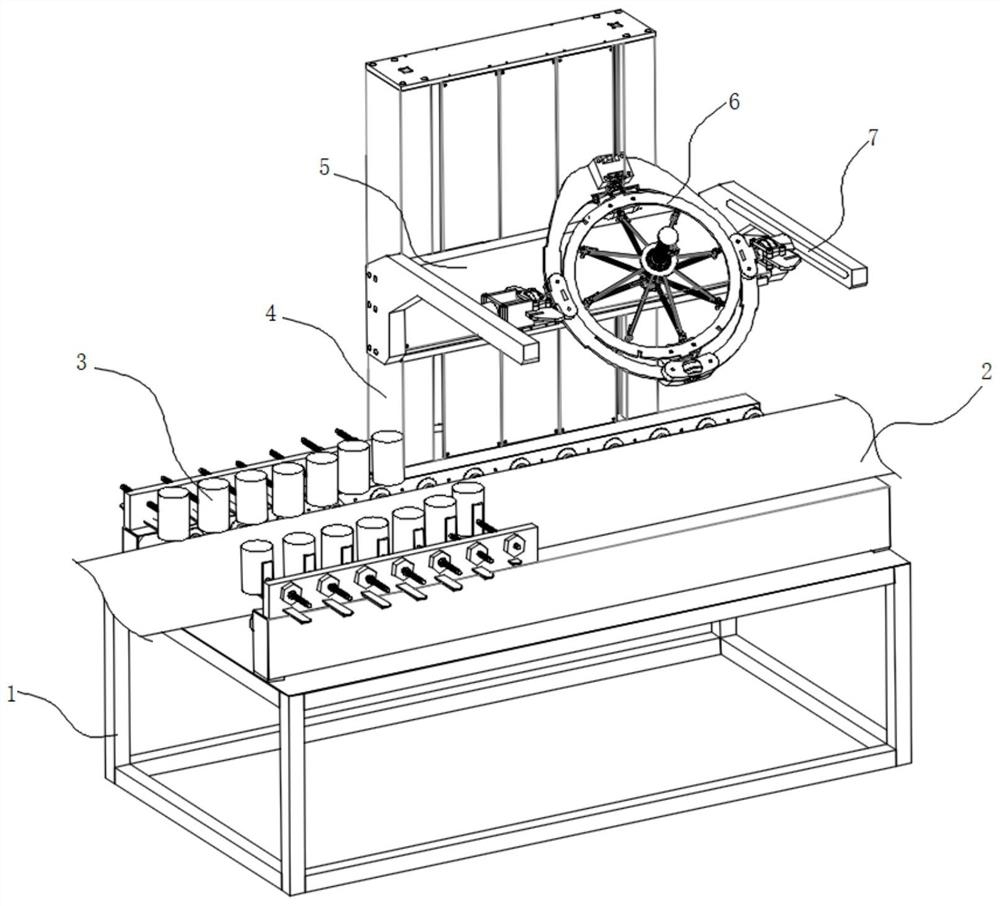

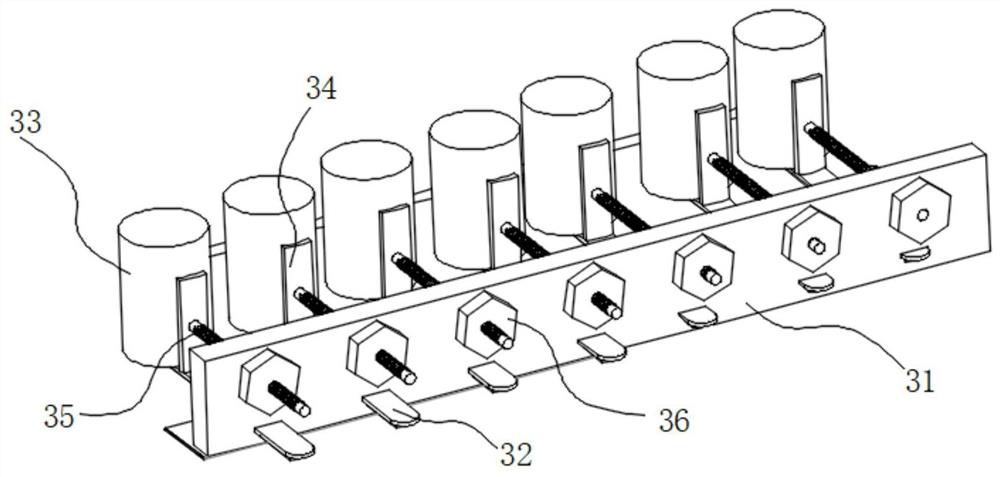

[0035] see figure 1 , In the embodiment of the present invention, a high-precision sensing device for a smart factory includes a base 1 and a scanning assembly 6. A conveyor belt 2 is fixed on the base 1, and the conveyor belt 2 is respectively connected to the input of the items to be identified in the production line. end and output end, the conveyor belt 2 is respectively provided with an offset assembly 3 and a scanning assembly 6 along the direction from the input end to the output end;

[0036] The offset assembly 3 can guide objects of different sizes on the conveyor belt 2 to center or offset;

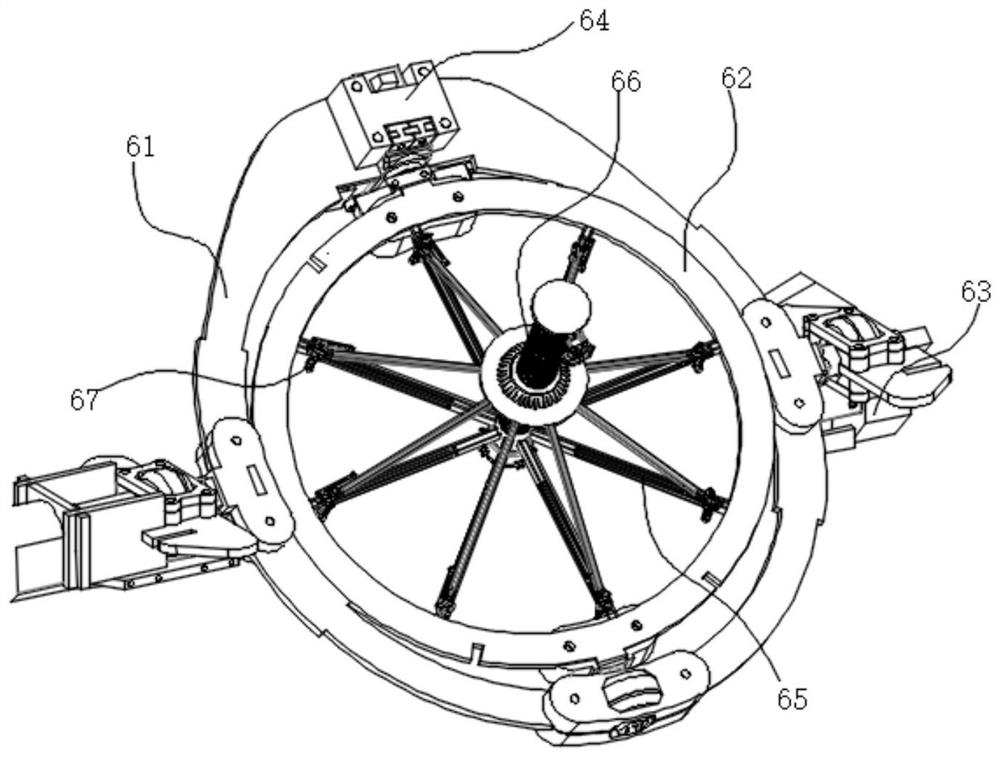

[0037] A lift frame 4 is fixed on the base 1 on one side of the conveyor belt 2 , and a lift table 5 is arranged in the lift frame 4 to move up and down in the direction of the conveyor belt 2 . A scanning assembly 6 is movably provided;

[0038] The lifting frame 4 is provided with a driving device capable of driving the lifting platform 5 to move;

[0039] The lifting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com