A Positioning Fixture for Processing Spherical Parts

A technology for positioning fixtures and parts processing, which is applied in the direction of manufacturing tools, positioning devices, metal processing equipment, etc., can solve the problems of long alignment time, low processing efficiency, and poor coaxiality in the processing process, and achieve reasonable and ingenious design. The effect of stable precision and guaranteed surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

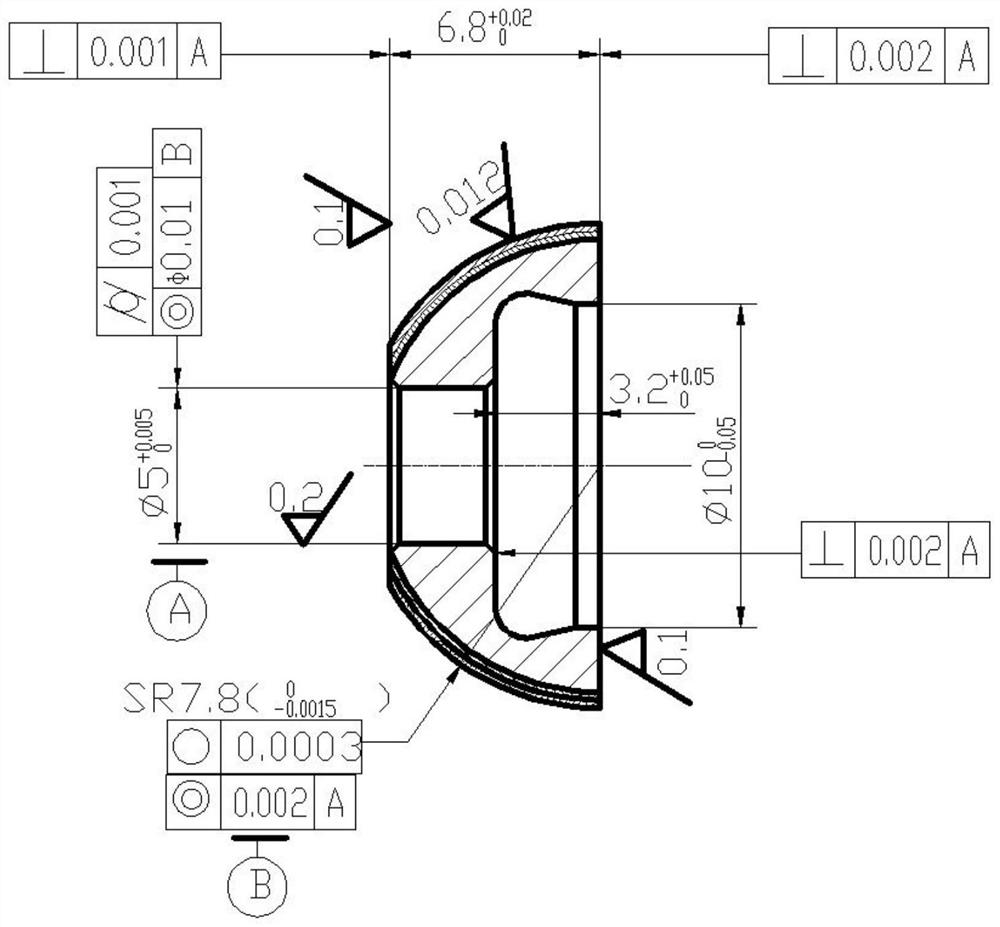

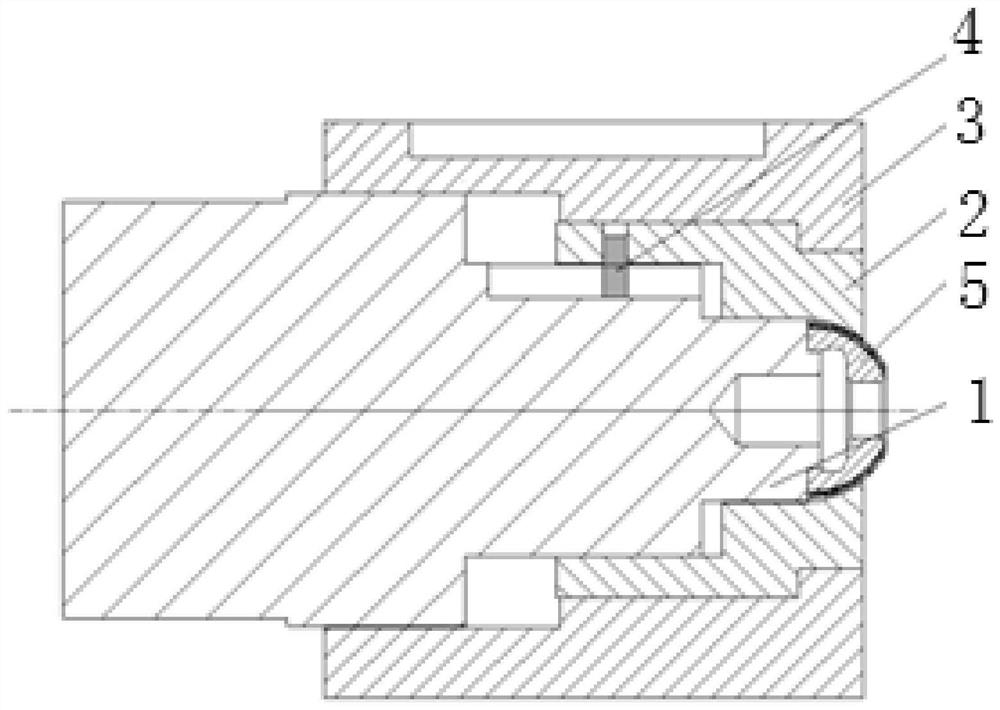

[0040] In this embodiment, the processed spherical parts are the left and right hemispheres used in a certain type of dynamic pressure motor, that is, the processed spherical parts are hemispherical parts, such as figure 2 As shown, the positioning fixture includes a mandrel 1, a positioning sleeve 2, a locking compression sleeve 3 and a positioning pin 4;

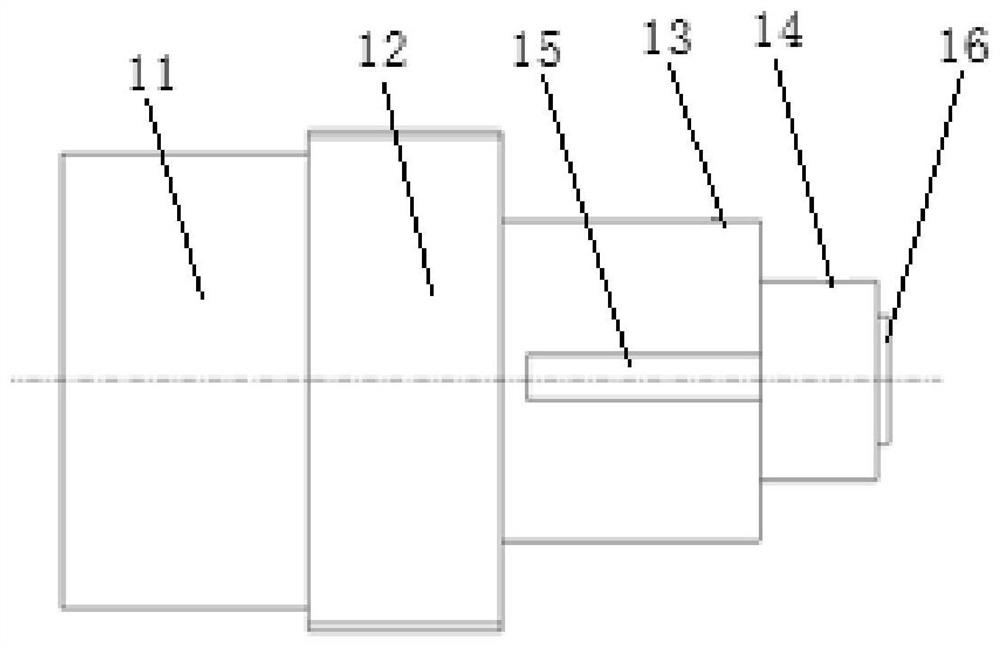

[0041] Such as figure 2 with image 3 As shown, the mandrel 1 includes a clamping section 11, a threaded connection section 12, a circumferential positioning section 13, and an axial positioning section 14 arranged in sequence; the clamping section 11 is used for clamping of a processing machine tool; Screw thread; On the circumferential positioning section 13, there is an opening positioning groove 15 along the axial direction; figure 1 The φ10 hole in the hole is a dismounting hole), so the end face of the axial positioning section in this embodiment is also provided with a columnar protrusion 16, and the outer diame...

Embodiment 2

[0047] In this embodiment, the processed spherical part is a complete spherical part, and the structure of the positioning fixture adopted is basically the same as that of Embodiment 1. See figure 1 , the difference is that the end face of the axial positioning section is in contact with the spherical part in a different way, and the specific structure has the following two types:

[0048] 1: The end face of the axial positioning section is provided with a groove, and the opening of the groove is processed with a circular chamfer, and the outer spherical surface of the spherical part can be initially positioned through the circular chamfer.

[0049] 2: The end face of the axial positioning section is provided with a spherical groove, and the radius of curvature of the spherical groove matches the radius of the processed spherical part, which can ensure more accurate positioning.

[0050] Above two embodiments also have following optimization design:

[0051] 1. In order to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com