Grain-oriented electrical steel sheet and method for producing same

A technology of oriented electrical steel sheets and electrical steel sheets, which is applied in the manufacture of tools, circuits, electrical components, etc., can solve the problems of unsmooth nitriding, complex annealing process of hot-rolled sheets, and difficult decarburization, etc., and achieve the effect of improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

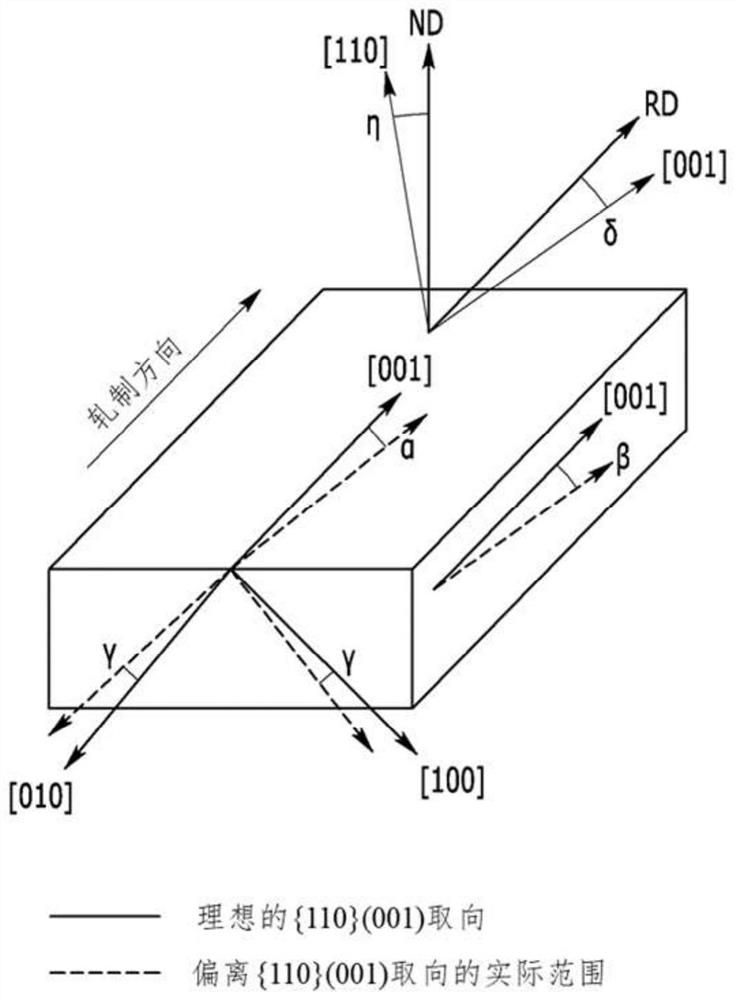

Method used

Image

Examples

Embodiment

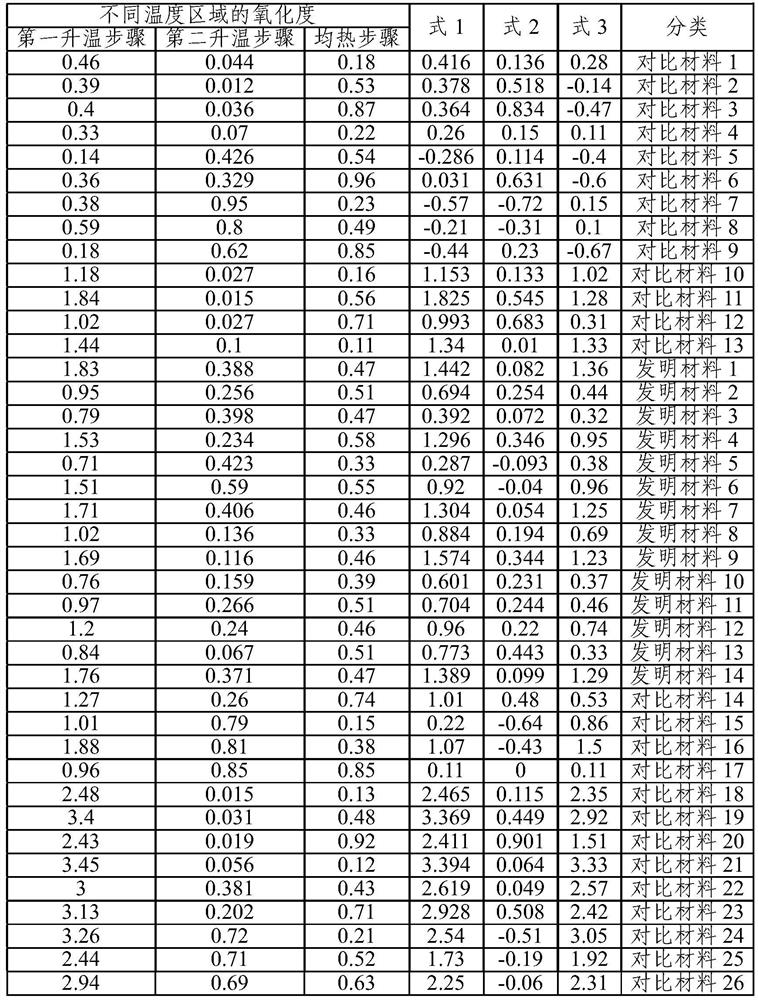

[0145] In weight %, the steel contains Si: 3.4%, C: 0.06%, S: 0.005%, N: 0.005%, Al: 0.029%, Sb: 0.027%, Sn: 0.065%, P: 0.030%, Cr: 0.04 % and Co: 0.032%, and the remaining ingredients include the balance of Fe and other unavoidable impurities. The steel is vacuum melted and made into an ingot, then heated at a temperature of 1150 ° C, and then hot rolled into a thickness of 2.3mm. After the hot-rolled sheet is heated to 1085°C, it is kept at 920°C for 160 seconds, and then rapidly cooled in water. Pickle the hot-rolled annealed sheet, then roll it to a thickness of 0.23 mm, and then control the environment of the first heating step, the second heating step and the soaking step according to the degree of oxidation shown in Table 1 below. Maintain and carry out decarburization and nitriding in a mixed gas environment, so that the carbon content is less than or equal to 30ppm, and the nitrogen content reaches 170ppm. The first heating step is carried out on average at normal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com