Lifting equipment, car loading platform and battery swapping station

A technology for replacing power stations and equipment, which is applied to charging stations, lifting frames, lifting devices, etc., and can solve the problems of reduced flexibility in application conditions and increased overall cost of power stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] The present invention is further illustrated below by means of examples, but the present invention is not limited to the scope of the following examples.

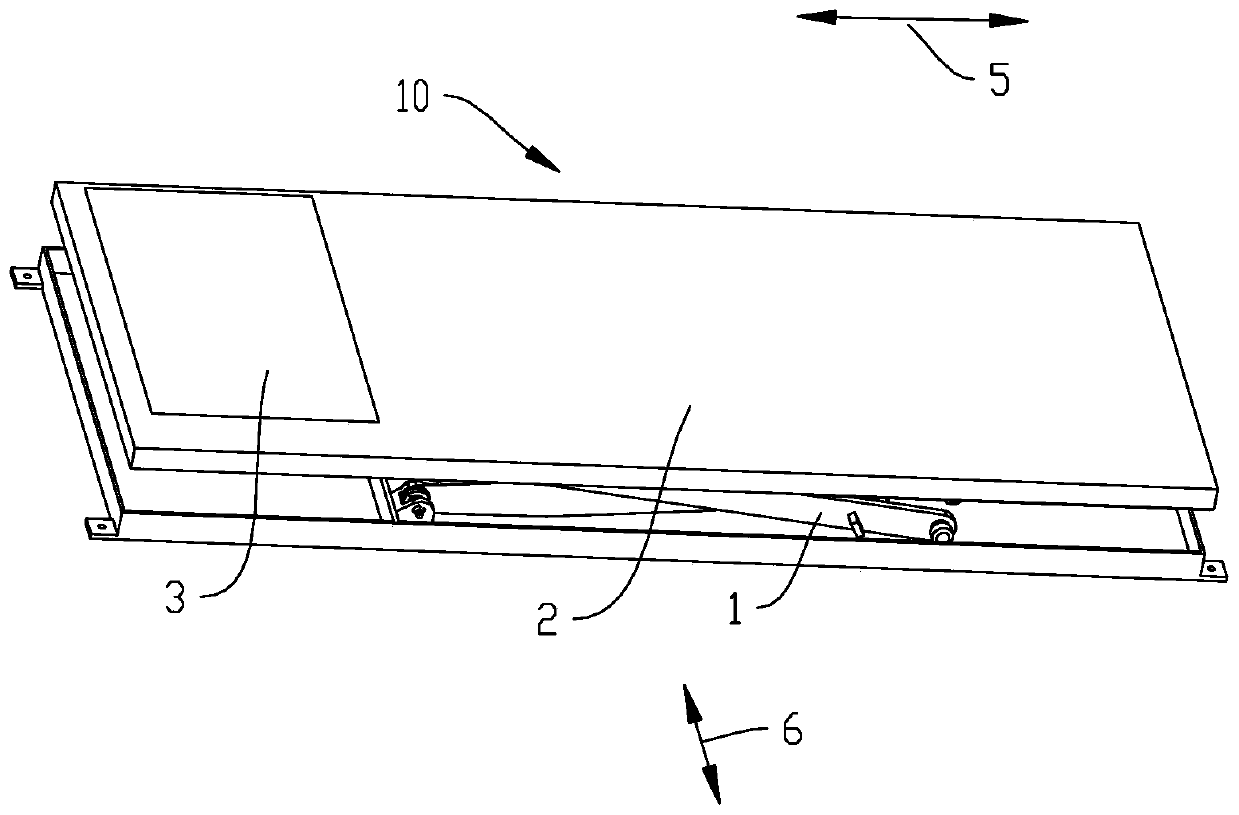

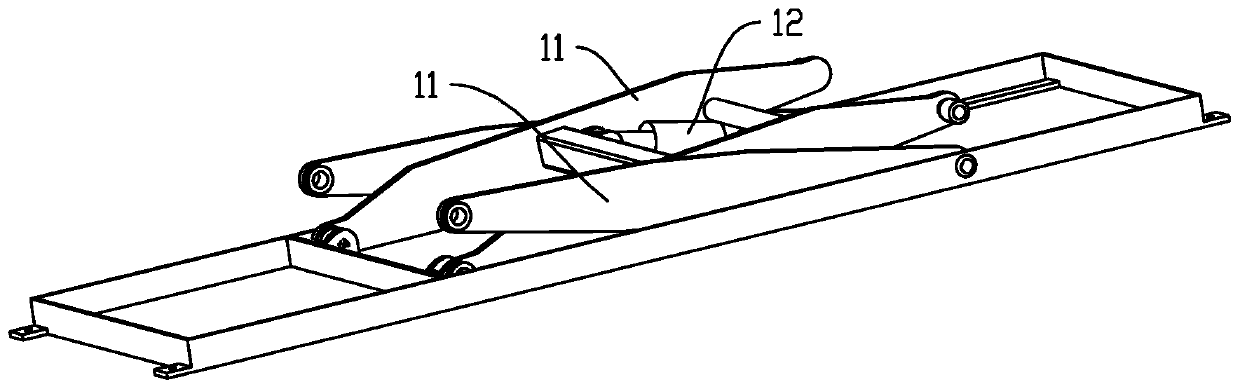

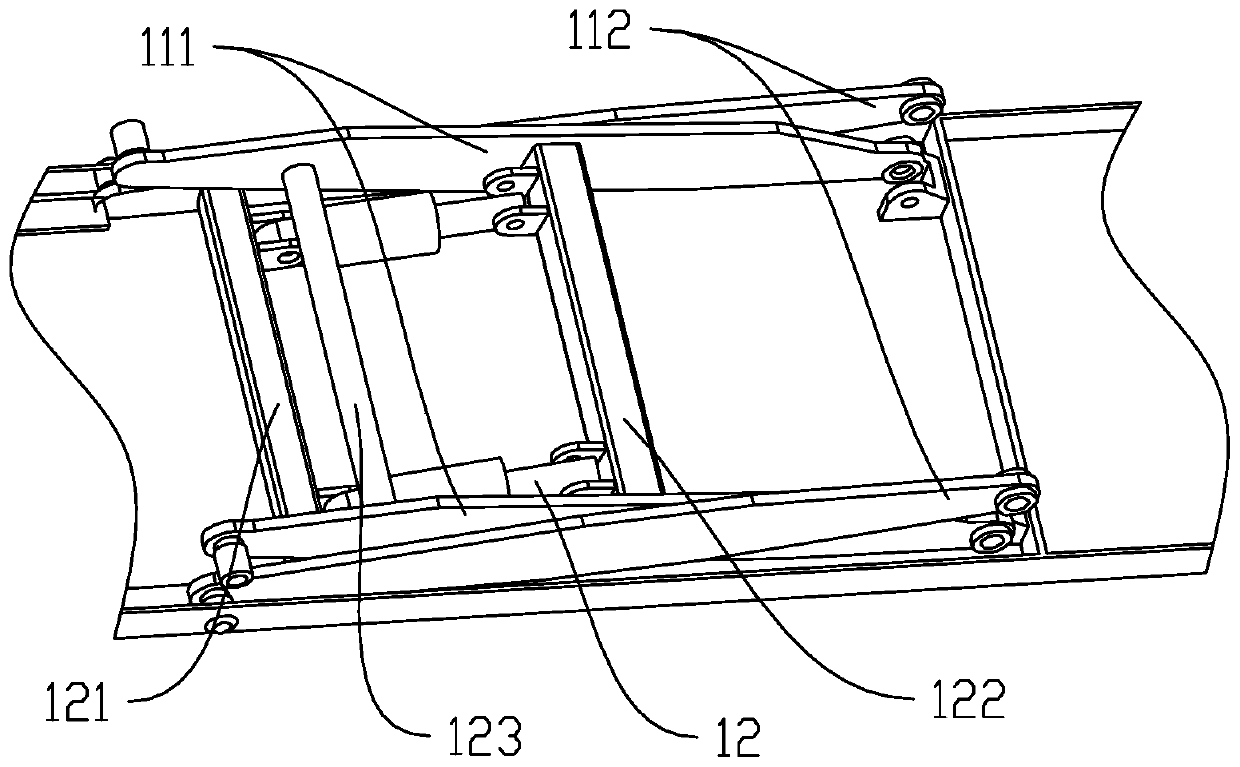

[0110] see figure 1 , the embodiment of the present invention provides a lifting device 10 for lifting and lowering an electric vehicle located in a substation 1000 ; Wherein, the lifting part 1 is arranged in the substation 1000; the worktable part 2 is arranged on the lifting part 1, and is used to carry the electric vehicle, and the lifting part 1 is used to realize the lifting of the worktable part 2; the guide part 3 is used The wheels of the electric vehicle are guided to a preset route, and the electric vehicle is kept on the preset route.

[0111] Specifically, the battery swapping station 1000 has a battery swapping room, a charging room, and battery swapping equipment. The battery swapping room can be used for replacing battery packs of electric vehicles, and the charging room can store batteries and provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com