Method for reducing center segregation of low-alloy steel continuous casting billet

A technology for low alloy steel and continuous casting slabs, which is applied in the field of reducing central segregation of low alloy steel continuous casting slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

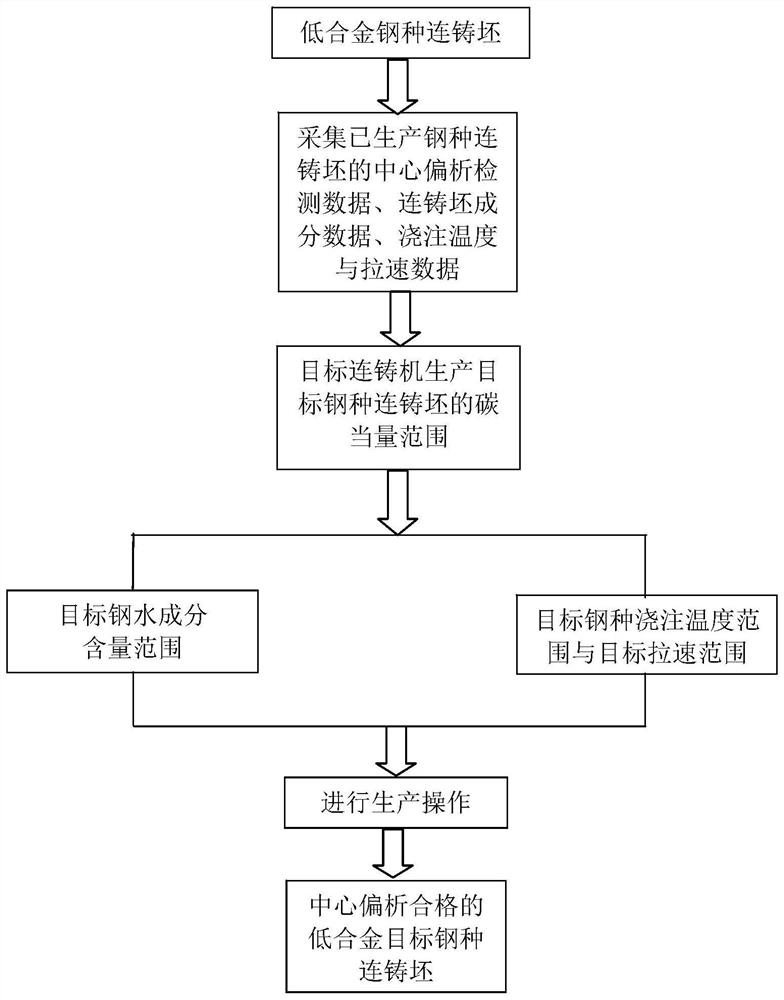

Method used

Image

Examples

Embodiment 1

[0051] The original specific control process of the continuous casting machine production is as follows:

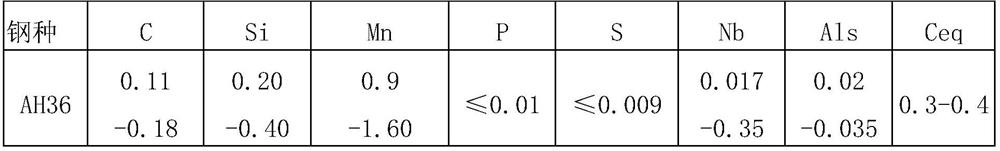

[0052] (1) AH36 steel production composition control range

[0053] The continuous casting machine controls the composition according to Table 1 when producing high-strength ship plate steel AH36.

[0054] Table 1 Composition / wt% of high-strength ship plate steel AH36

[0055]

[0056] (2) AH36 steel molten steel pouring temperature and casting speed of continuous casting machine

[0057] When the continuous casting machine produces high-strength ship plate steel AH36, the pouring temperature and casting speed of the continuous casting machine are shown in Table 2.

[0058] Table 2 Continuous casting parameters of original high-strength ship plate steel AH36

[0059] target carbon equivalent range Test molten steel pouring temperature / ℃ Pulling speed of test casting machine / m / min [Ceq]=0.3-0.4 1525-1550 1.3-1.6

[0060] (3) Production opera...

Embodiment 2

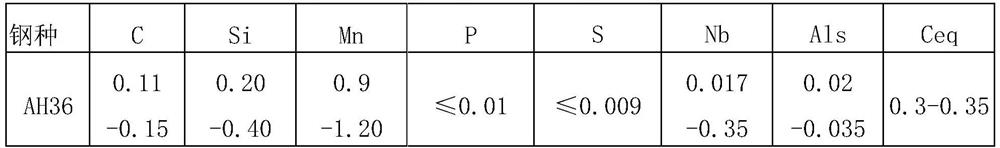

[0063] In the present embodiment, when this continuous casting machine produces AH36 slab, take and comprise the following production control steps:

[0064] (1) According to the center segregation detection results of the AH36 slab in the historical production data, find out the target continuous casting slab;

[0065] (2) Calculate the carbon equivalent of the target continuous casting slab according to the formula (1), and according to the statistical analysis of the carbon equivalent of the target continuous casting slab, when [Ceq]<0.35, the slab center segregation is satisfied under certain conditions Able to achieve 100% pass rate of B0.5 grade, that is, the target carbon equivalent range includes [Ceq]<0.35;

[0066] (3) According to the target carbon equivalent range of [Ceq]<0.35, based on the formula (2), determine the optimal content range of the composition of AH36 steel, that is, to obtain the composition content range of the target molten steel. The composition ...

Embodiment 3

[0074] In the present embodiment, when this continuous casting machine produces AH36 slab, take and comprise the following production control steps:

[0075] (1) According to the center segregation detection results of the AH36 slab in the historical production data, find out the target continuous casting slab;

[0076] (2) Calculate the carbon equivalent of the target continuous casting slab according to the formula (1), and according to the statistical analysis of the carbon equivalent of the target continuous casting slab, when [Ceq]>0.37, the slab center segregation is satisfied under certain conditions It can also achieve 100% pass rate of B0.5 grade, that is, the target carbon equivalent range also includes [Ceq]>0.37;

[0077] (3) According to the target carbon equivalent range of [Ceq]>0.37, based on the formula (2), determine the optimal content range of the components of AH36 steel, that is, the target molten steel component content range, the target molten steel com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com