Electric spark machine tool capable of effectively avoiding damage caused by electric spark

An EDM machine tool and EDM technology, which is applied in manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve the problems of limited EDM elimination effect, influence of EDM machine tool, temperature rise of dielectric fluid, etc., and facilitates recycling The effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

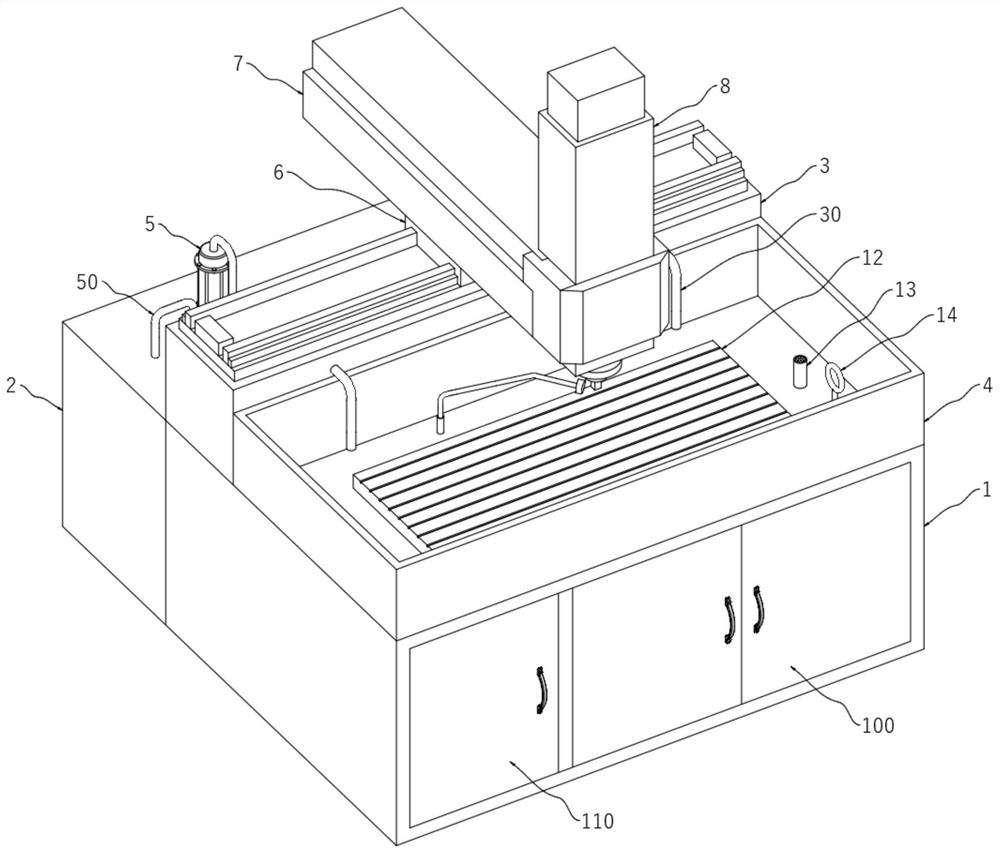

Embodiment 1

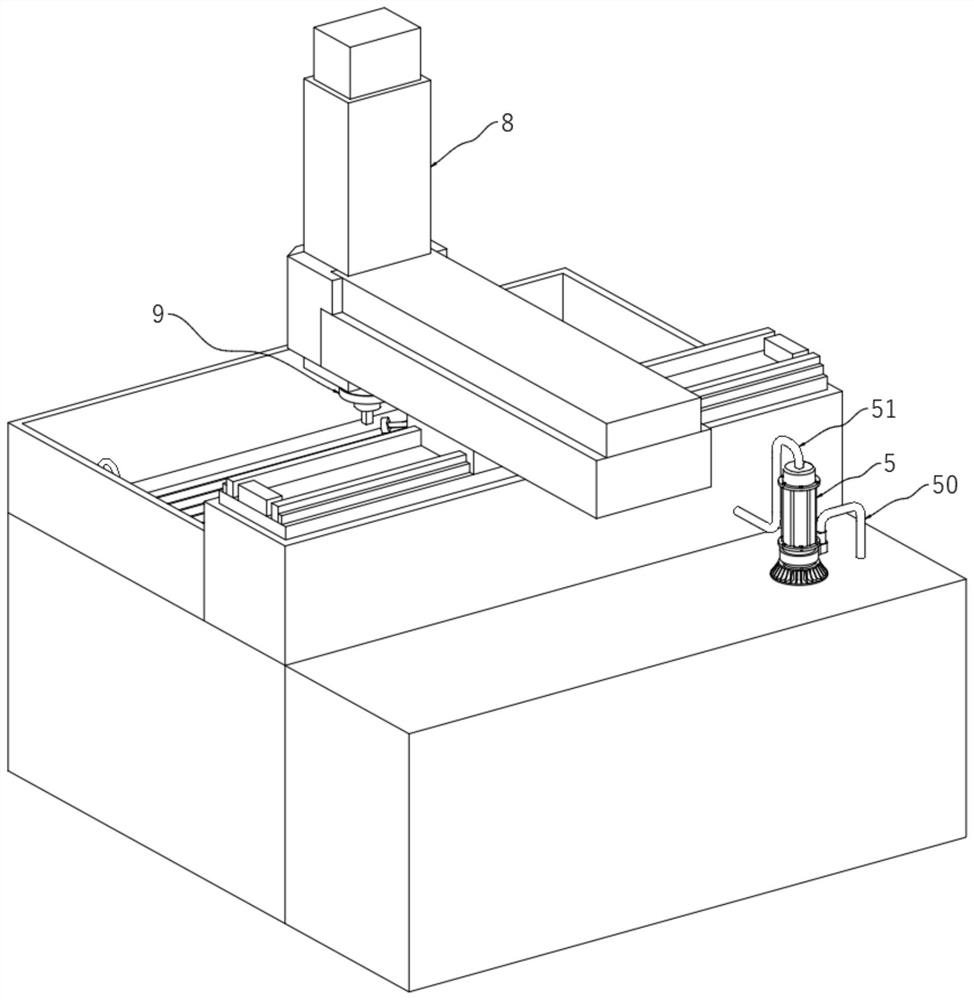

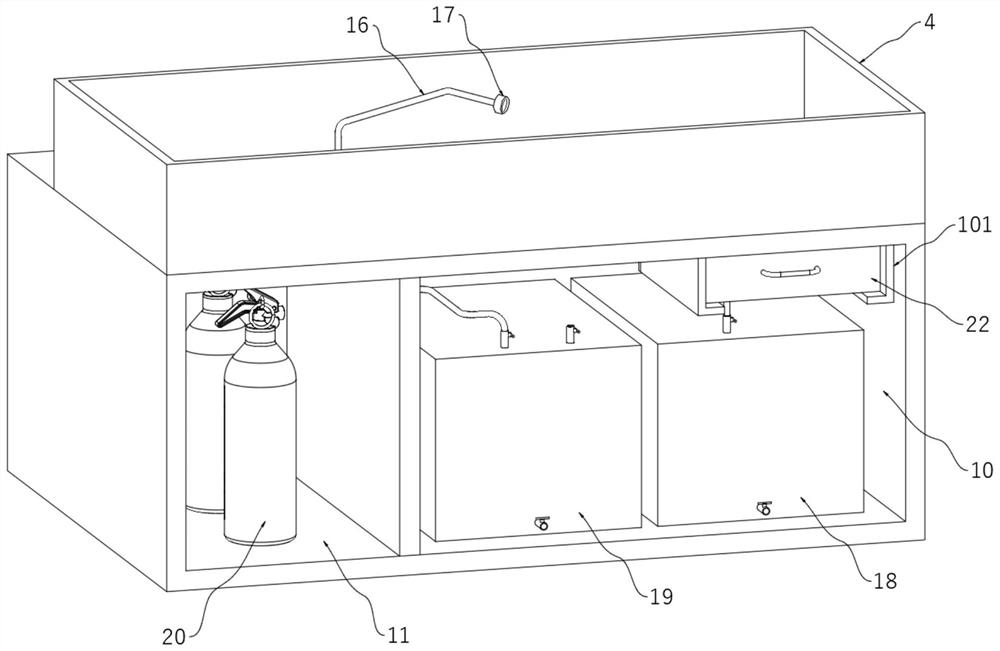

[0034]The electric discharge machine tool of the present invention, which can effectively avoid damage caused by electric sparks, includes a box body 1, a first liquid storage tank 2 is provided on the rear side of the box body 1, and is used to store machining fluid. The top of the first liquid storage box 2 is provided with There is a first self-priming pump 5, the first self-priming pump 5 is connected to the inside of the first liquid storage tank 2 through the first liquid suction pipe 50, and the first self-priming pump 5 passes the first liquid storage tank 5 through the first liquid suction pipe 50. The processing fluid in the box 2 is pumped out. The top of the box body 1 is provided with a refrigeration box 3 and a processing tank 4. The refrigeration box 3 is located on the rear side of the top of the box body 1. There is a serpentine pipeline inside the refrigeration box 3. The first self-priming pump 5. The first liquid delivery pipe 51 is connected to the input en...

Embodiment 2

[0036] The electric discharge machine tool of the present invention, which can effectively avoid damage caused by electric sparks, includes a box body 1, a first liquid storage tank 2 is provided on the rear side of the box body 1, and is used to store machining fluid. The top of the first liquid storage box 2 is provided with There is a first self-priming pump 5, the first self-priming pump 5 is connected to the inside of the first liquid storage tank 2 through the first liquid suction pipe 50, and the first self-priming pump 5 passes the first liquid storage tank 5 through the first liquid suction pipe 50. The processing fluid in the box 2 is pumped out. The top of the box body 1 is provided with a refrigeration box 3 and a processing tank 4. The refrigeration box 3 is located on the rear side of the top of the box body 1. There is a serpentine pipeline inside the refrigeration box 3. The first self-priming pump 5. The first liquid delivery pipe 51 is connected to the input e...

Embodiment 3

[0039] The electric discharge machine tool of the present invention, which can effectively avoid damage caused by electric sparks, includes a box body 1, a first liquid storage tank 2 is provided on the rear side of the box body 1, and is used to store machining fluid. The top of the first liquid storage box 2 is provided with There is a first self-priming pump 5, the first self-priming pump 5 is connected to the inside of the first liquid storage tank 2 through the first liquid suction pipe 50, and the first self-priming pump 5 passes the first liquid storage tank 5 through the first liquid suction pipe 50. The processing fluid in the box 2 is pumped out. The top of the box body 1 is provided with a refrigeration box 3 and a processing tank 4. The refrigeration box 3 is located on the rear side of the top of the box body 1. There is a serpentine pipeline inside the refrigeration box 3. The first self-priming pump 5. The first liquid delivery pipe 51 is connected to the input e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com