Modified building material and processing device and method thereof

A processing device and building material technology, applied in wood processing equipment, manufacturing tools, special forming/shaping machines, etc., can solve problems such as inability to process building material base plates, wall bulges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

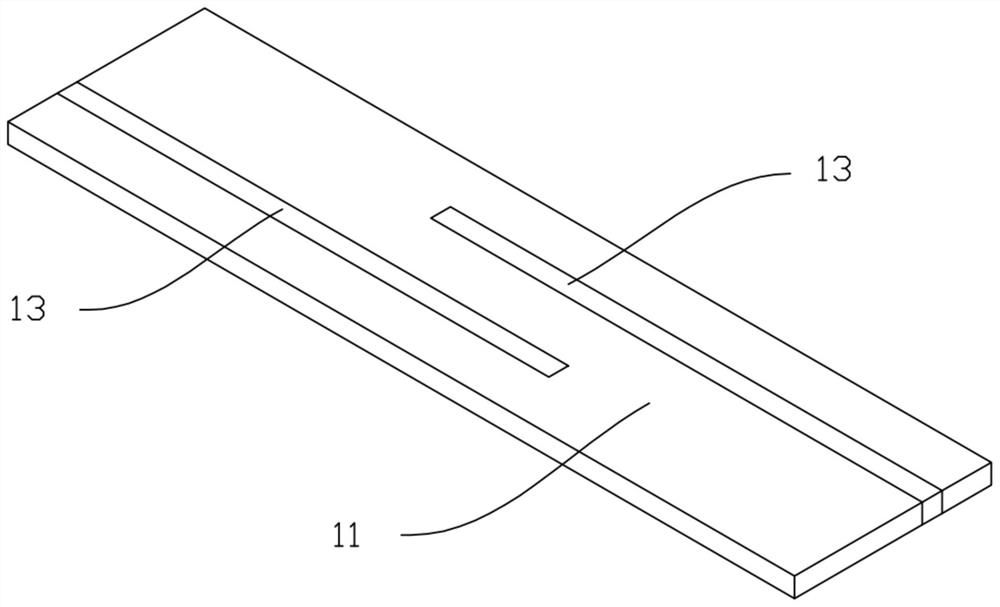

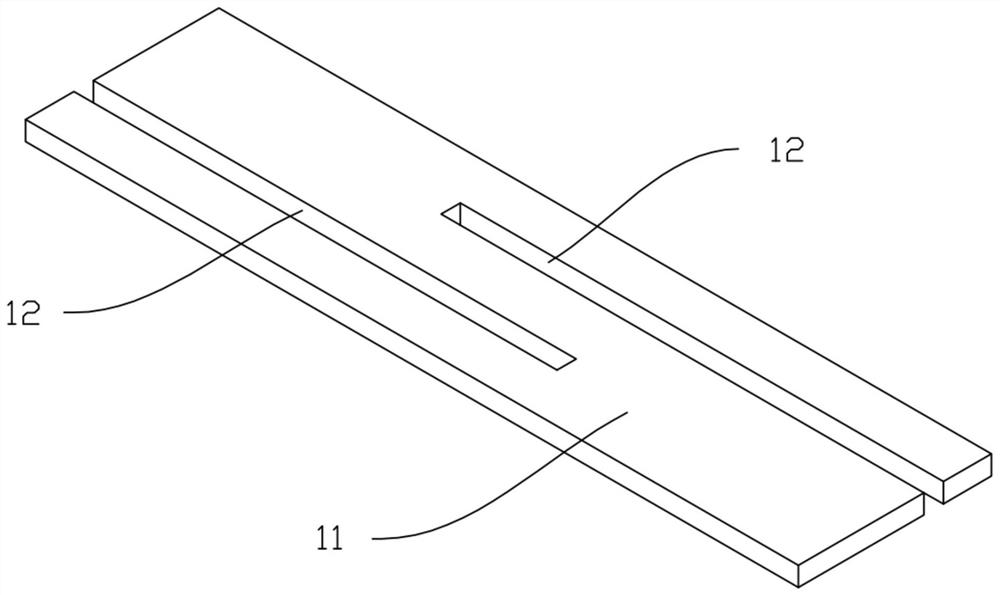

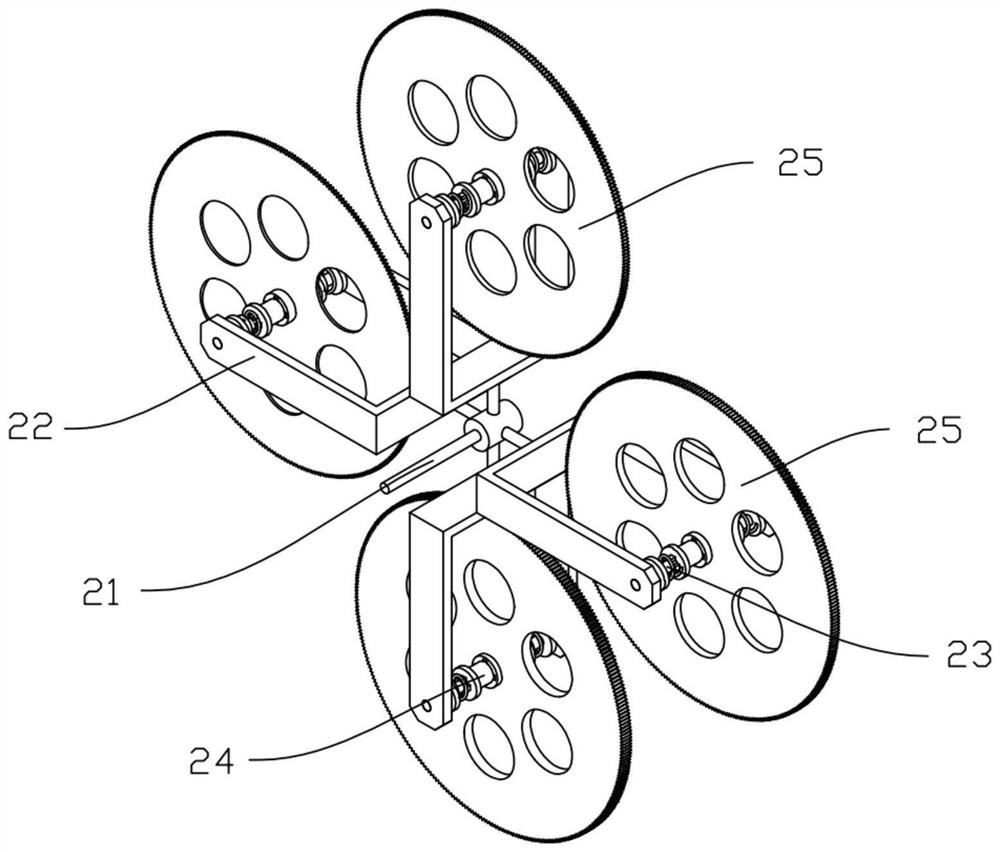

[0029] Combine below Figures 1 to 10 Describe this embodiment, a modified building material processing device, including a cutting mechanism, a power mechanism I30, a moving mechanism, a device bracket 50, a power mechanism II, a power mechanism III70, and a refueling mechanism. The cutting mechanism includes a tool change shaft 21, a cutting bracket 22. Cutting shaft 23, mounting sleeve 24 and cutting tool 25, multiple cutting brackets 22 are fixedly connected on the tool changing shaft 21, and two cutting shafts 23 are connected in rotation on each cutting bracket 22, and the two cutting shafts 23 The inner side is slidingly connected with the installation sleeve 24, and the compression spring I is fixedly connected between the installation sleeve 24 and the cutting shaft 23, and the cutting tool 25 is fastened between the corresponding two installation sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com