Metal material transportation device

A technology for transportation devices and metal materials, applied in transportation and packaging, multi-axis trolleys, trolley accessories, etc., can solve problems such as inability to transport metal materials, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

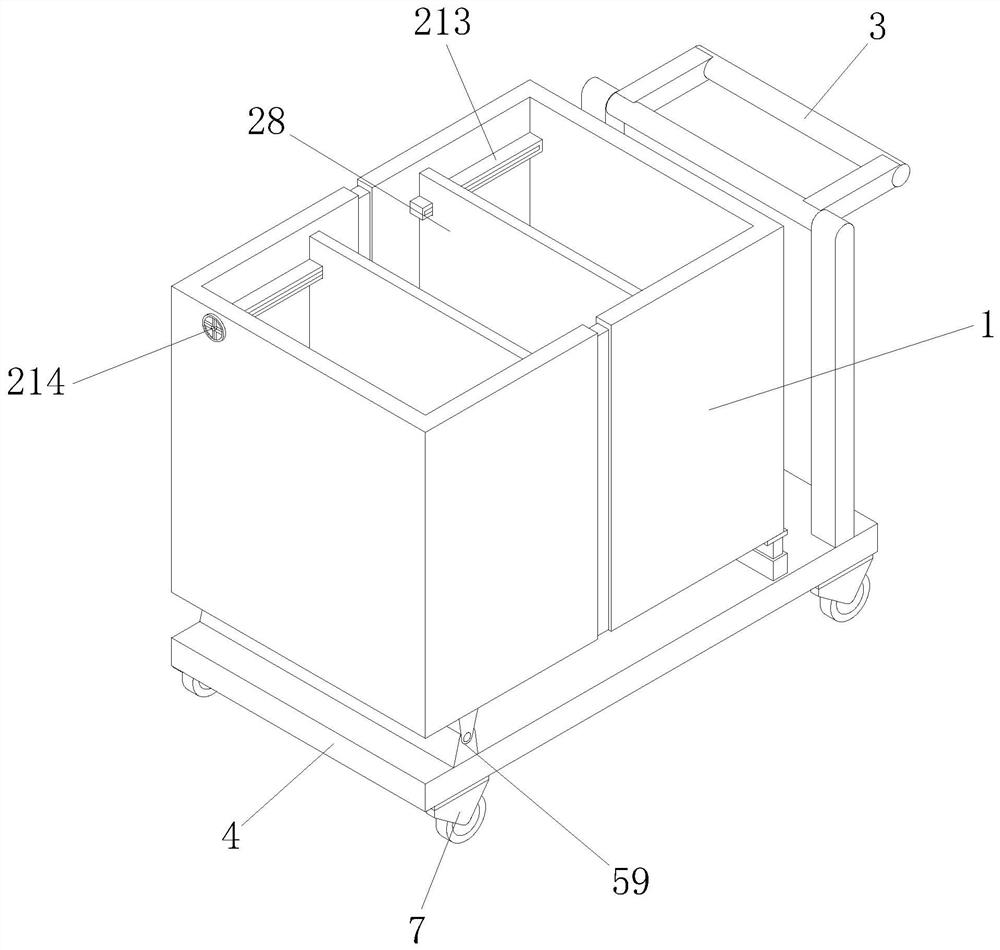

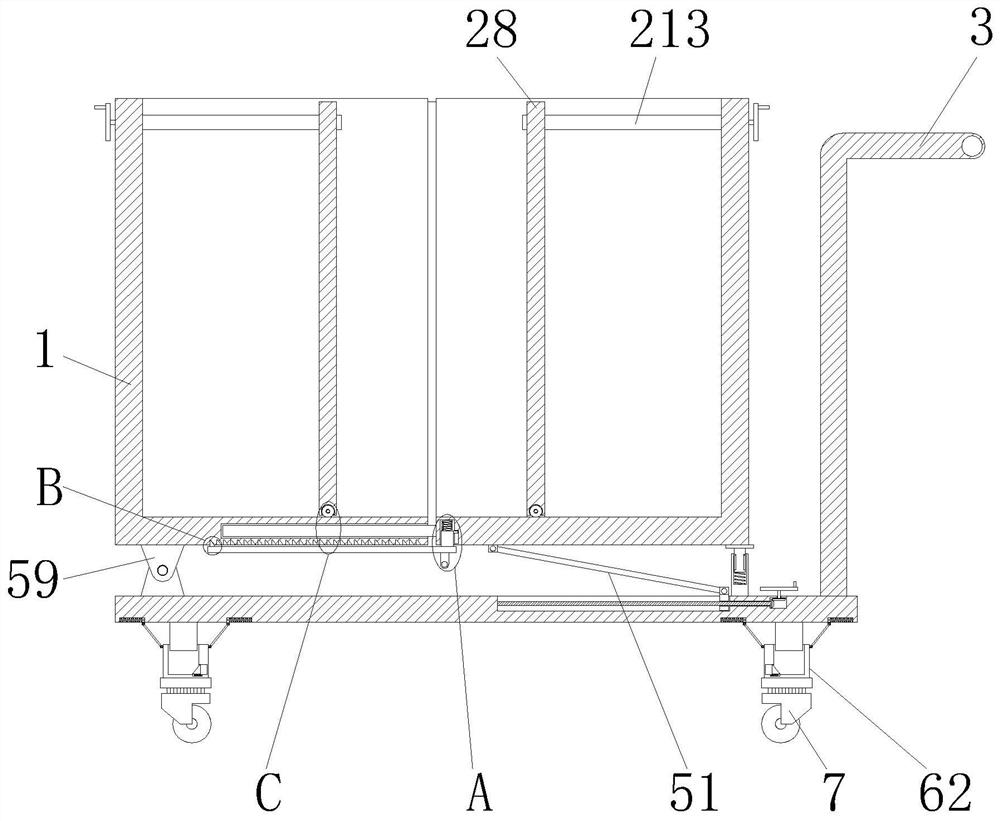

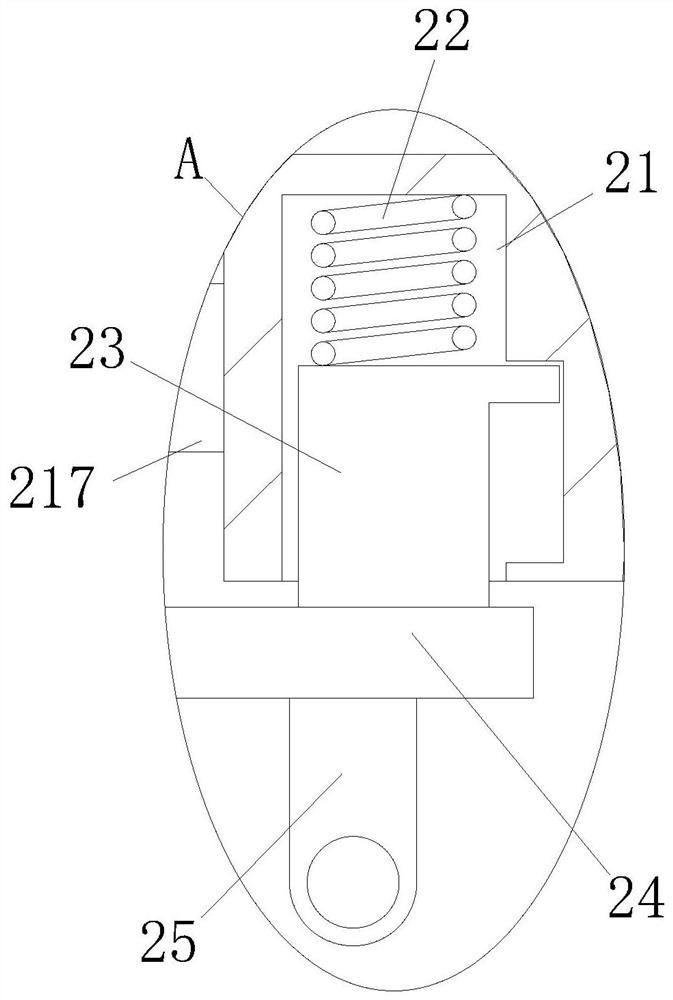

[0034] see Figure 1-14As shown, a transportation device for metal materials includes a storage bin 1, a handrail 3, a bottom plate 4 and a universal wheel 7; the storage bin 1 is provided with two groups, and the bottom ends of the storage bins 1 of the two groups are provided with a bottom plate 4. The bottom end of the storage bin 1 is provided with a base plate 4, and one side of the top end of the base plate 4 is fixedly connected with a handrail 3, and the bottom end of the base plate 4 is provided with a universal wheel 7; the inside of the storage bin 1 An adjustment mechanism is provided, and the adjustment mechanism includes a reset chamber 21, a first spring 22, a connection block 23, a connection plate 24, a block 26, a slot 27, a partition 28, a first screw sleeve 211, a first screw rod 212, Movable cavity 213, pulley 215, transmission belt 216, extension plate 217 and storage cavity 218, described reset cavity 21 is opened at the bottom end of storage bin 1 on th...

Embodiment 2

[0041] see Figure 15 As shown in Comparative Example 1, as another embodiment of the present invention, the top end of the inner side of the sleeve block 62 is fixedly connected with a third slider 613, and the third slider 613 is slidably connected to the third chute 614. Inside, the third chute 614 is provided on one side of the insert block 61; during operation, the third slider 613 moves along with the movement of the sleeve block 62, and slides inside the third chute 614 through the first The combination of the three sliding blocks 613 and the third sliding groove 614 limits the moving distance of the sleeve block 62, and at the same time, the third sliding block 613 and the third sliding groove 614 prevent the insertion block 61 from coming out of the sleeve block 62. effect.

[0042] The working principle is that when the volume of the storage bin 1 is to be enlarged, the storage bin 1 on the left side is pulled to the left, and under the action of the pulling force t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com