Cloth winding device capable of achieving automatic cutting and automatic cutting method

A winding device and fabric technology, which is applied in the field of automatic cutting and fabric winding devices for automatic cutting, can solve the problems of different specifications of fabrics, inability to meet customer needs, and the inability of fabric winding devices to cut independently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

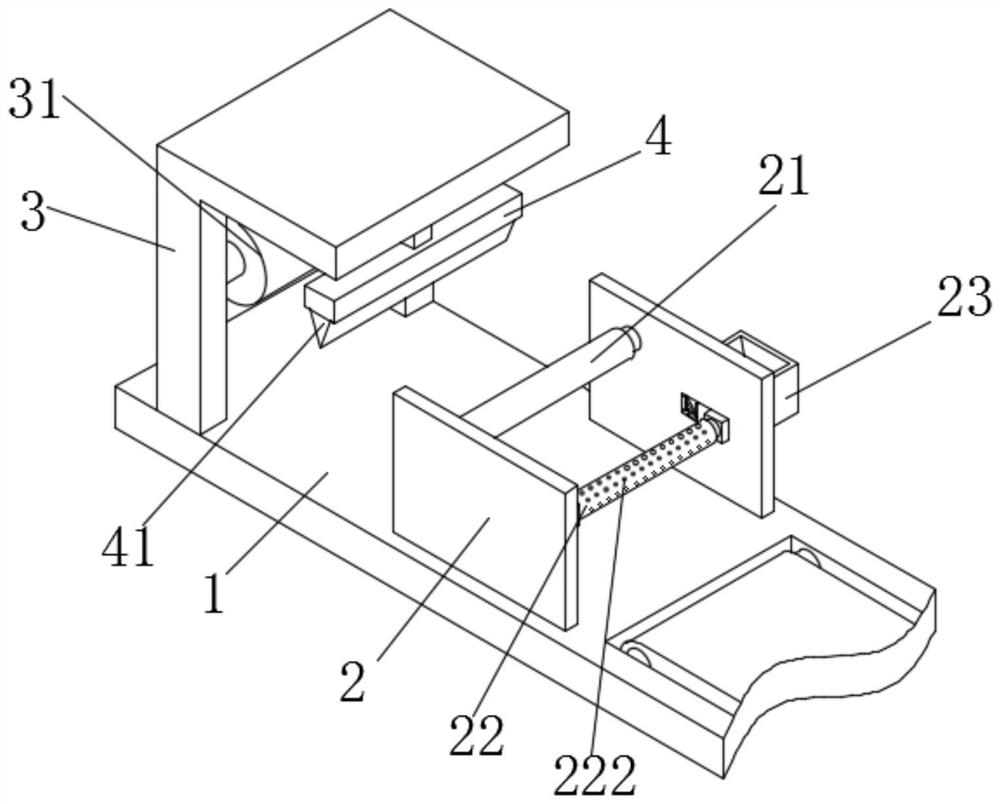

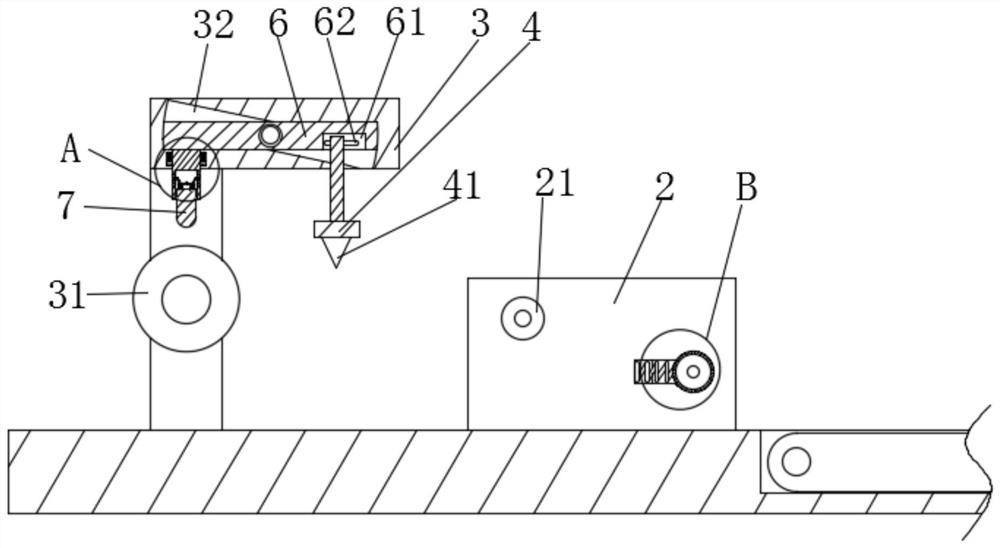

[0026] see figure 1 with image 3 , the present embodiment provides a cloth winding device capable of automatic cutting and an automatic cutting method, including a workbench 1, a conveyor belt is arranged on one side of the workbench 1, and a symmetrically arranged support plate 2 is fixedly installed on the top of the workbench 1. A first conveying roller 21 is arranged between the two support plates 2 to ensure that the cloth can be wound up more smoothly.

[0027] In a further embodiment, the outer surface of the first conveying roller 21 is provided with a plurality of bristles for removing fluff on the surface of the cloth, and the fluff of the cloth is scraped off by the bristles, thereby improving the production quality of the cloth.

[0028] A support frame 3 is fixedly installed on the upper surface of the workbench 1, and a winding roller 31 is installed in the middle part of the support frame 3 by a motor to wind the cloth.

[0029] In a further embodiment, the m...

Embodiment 2

[0035] see Figure 3-4 , a further improvement has been made on the basis of Embodiment 1: in order to facilitate the adjustment of the distance between the push block 7 and the winding roller 31, so that the cloth of different specifications can be cut, the push block 7 includes a slide block 71, the slide block The bottom of 71 is provided with a placement groove 711, and the inside of the placement groove 711 is slidably installed with a fitting block 72. By changing the sliding distance of the fitting block 72 inside the sliding block 71, the distance between the fitting block 72 and the winding roller 31 is changed. Pitch.

[0036] Preferably, the bottom of the fitting block 72 is set in a semicircular structure to reduce the friction between the fitting block 72 and the cloth, thereby ensuring the integrity of the cloth and preventing the cloth from being damaged when the force is applied to the fitting block 72 .

[0037] Inside the placement groove 711 is provided an ...

Embodiment 3

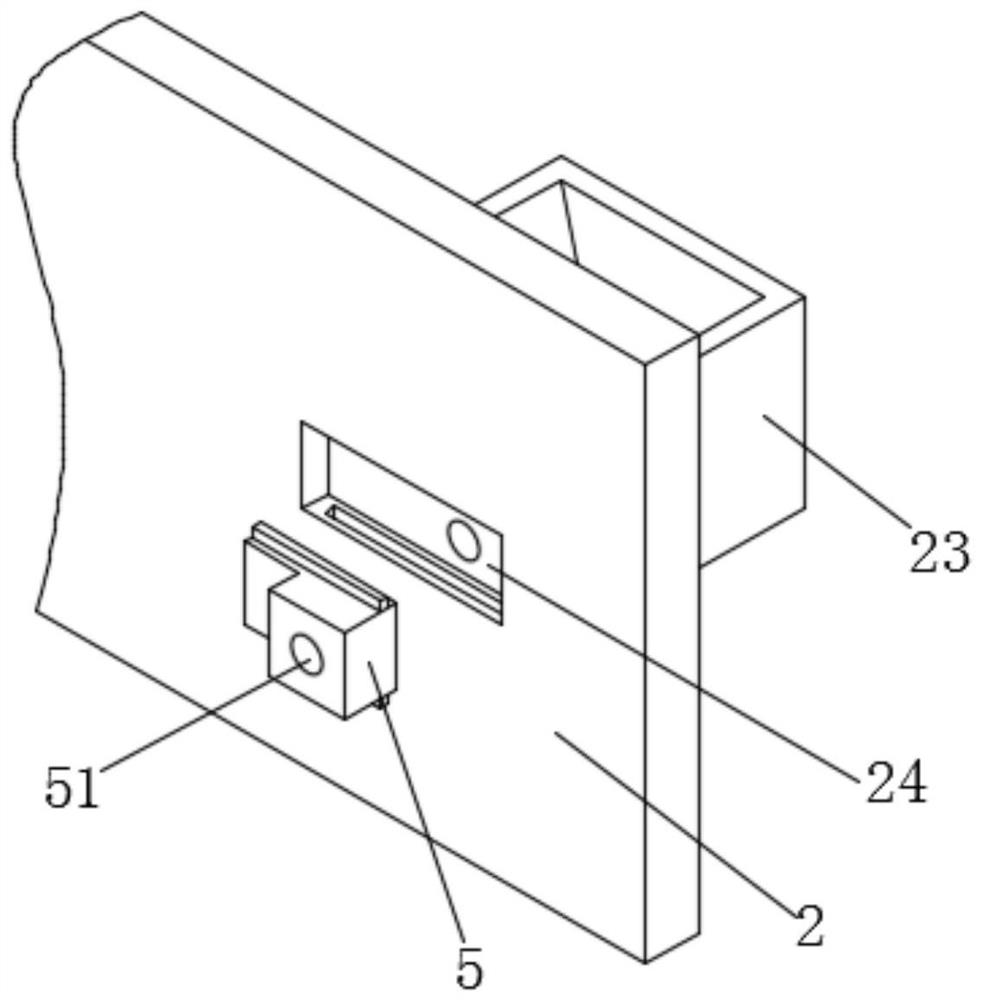

[0042] see Figure 1-2 and Figure 5 On the basis of Embodiment 2, a further improvement has been made: in order to realize the self-regulation of the tension force of the cloth, the inner walls of the two support plates 2 are provided with slide rails 24, and L-shaped blocks 5 are slidably installed inside the slide rails 24, A second conveying roller 22 is installed in rotation between the two L-shaped blocks 5, and an elastic assembly is connected between the inside of the slide rail 24 and the L-shaped block 5, and the elastic assembly drives the second conveying roller 22 to slide in the horizontal direction. When the tight force is too large, the L-shaped block 5 can be pushed to slide, and when the cloth stretching force is too small, the elastic component drives the second conveying roller 22 to squeeze the cloth, so that the cloth is always in the stretching state.

[0043] Preferably, there is a certain height difference between the second conveying roller 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com