Organic fertilizer fermentation chamber utilizing new energy

A technology of organic fertilizer and fermentation room, applied in the field of fermentation room, can solve the problems of uncontrollable rainwater addition flow and flow rate, laborious fertilizer turning, inconvenient adjustment, etc., achieve convenient ventilation and oxygen supply, good effect, and increase the pushing area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

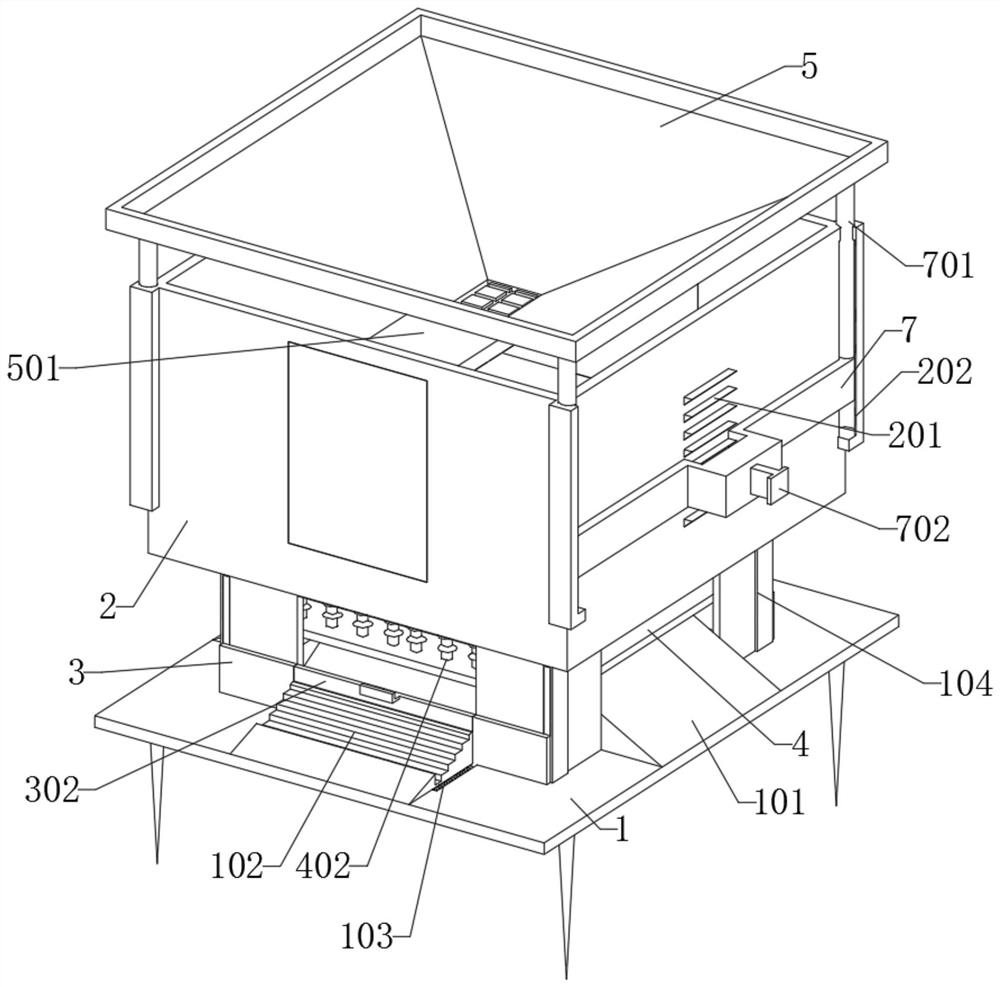

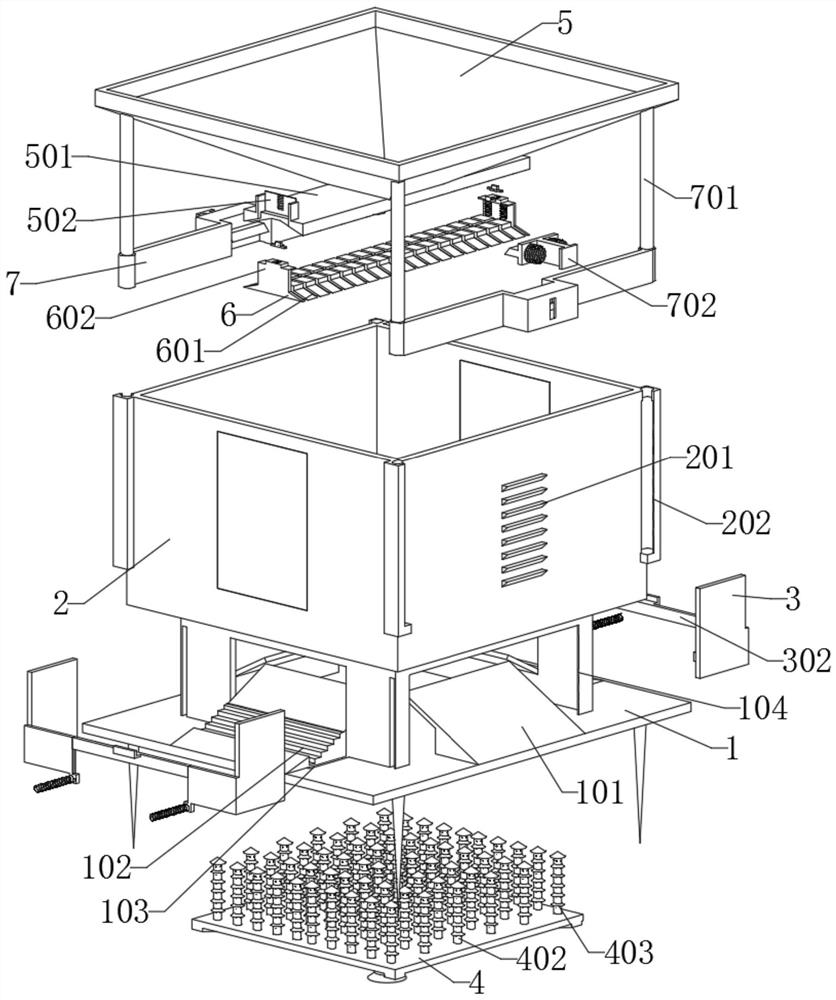

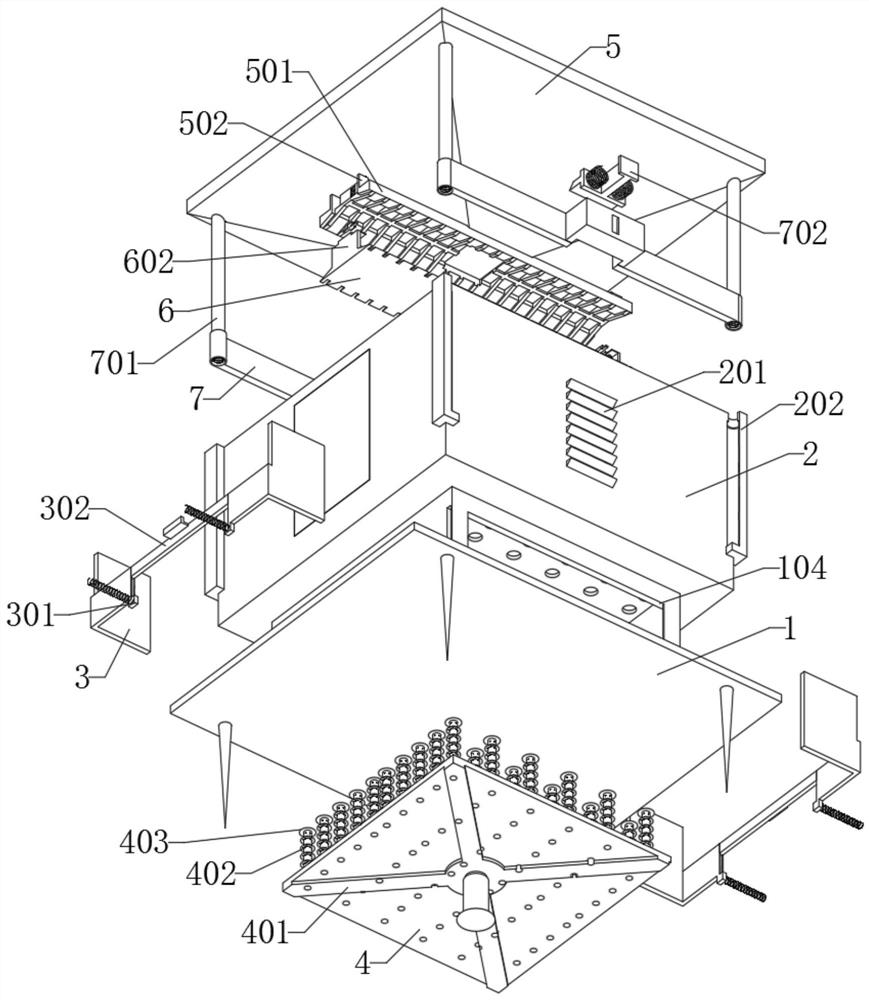

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035] The present invention provides an organic fertilizer fermentation room utilizing new energy, comprising a main body 1, a top piece 2, a moving plate 3, a top plate 4, a collecting piece 5, an adjustment piece 6 and an adjustment plate 7; the main body 1 is the body of the organic fertilizer fermentation room, And the main body 1 is a rectangular structure with a protrusion in the middle; the top piece 2 is installed on the top of the main body 1, and the inside of the top piece 2 communicates with the inside of the main body 1 through a round hole; the moving plate 3 is installed on the side of the main body 1, and moves The plate 3 is inserted into the outer groove 104 on both sides of the main body 1; the guide block 301 of the moving plate 3 is embedded in the bottom groove 103, and the bottom of the fixed plate 302 inside the moving plate 3 is embedded in the card groove 102; the collecting piece 5 There are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com