Pneumatic type pipe explosion safety valve and method

A safety valve, pneumatic technology, used in the field of shut-off valves, can solve the problems of inconvenient adjustment, failure, and small elastic coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

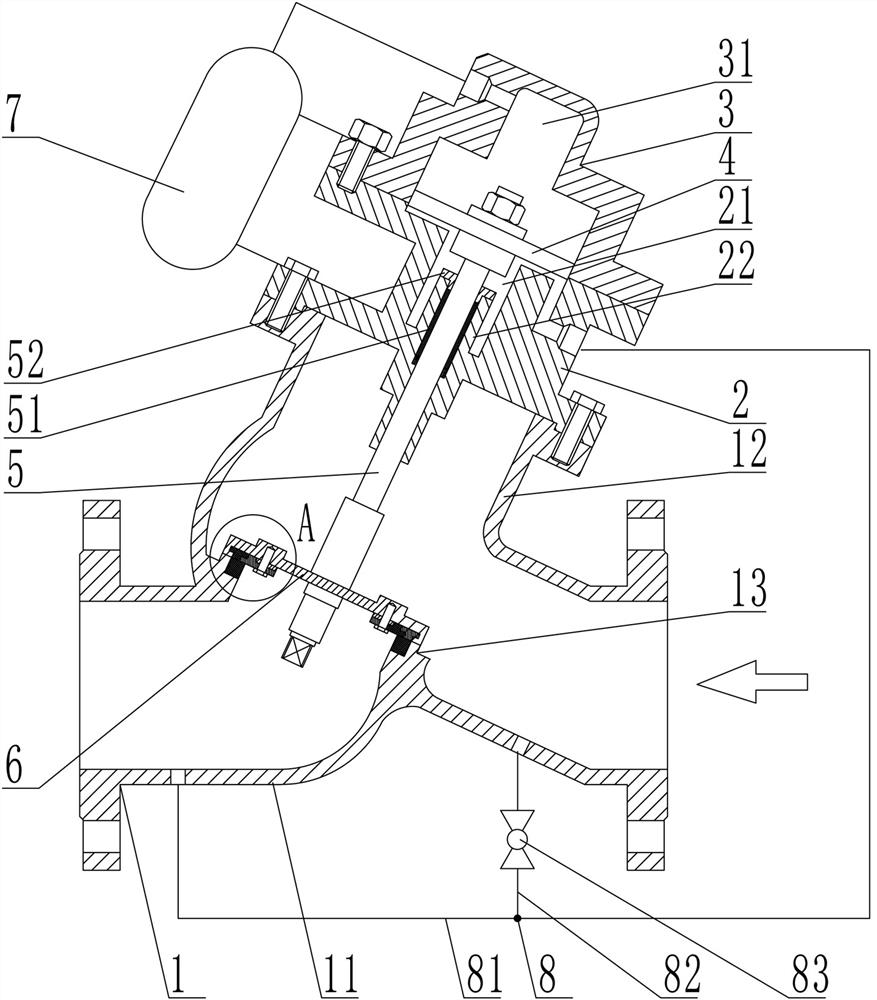

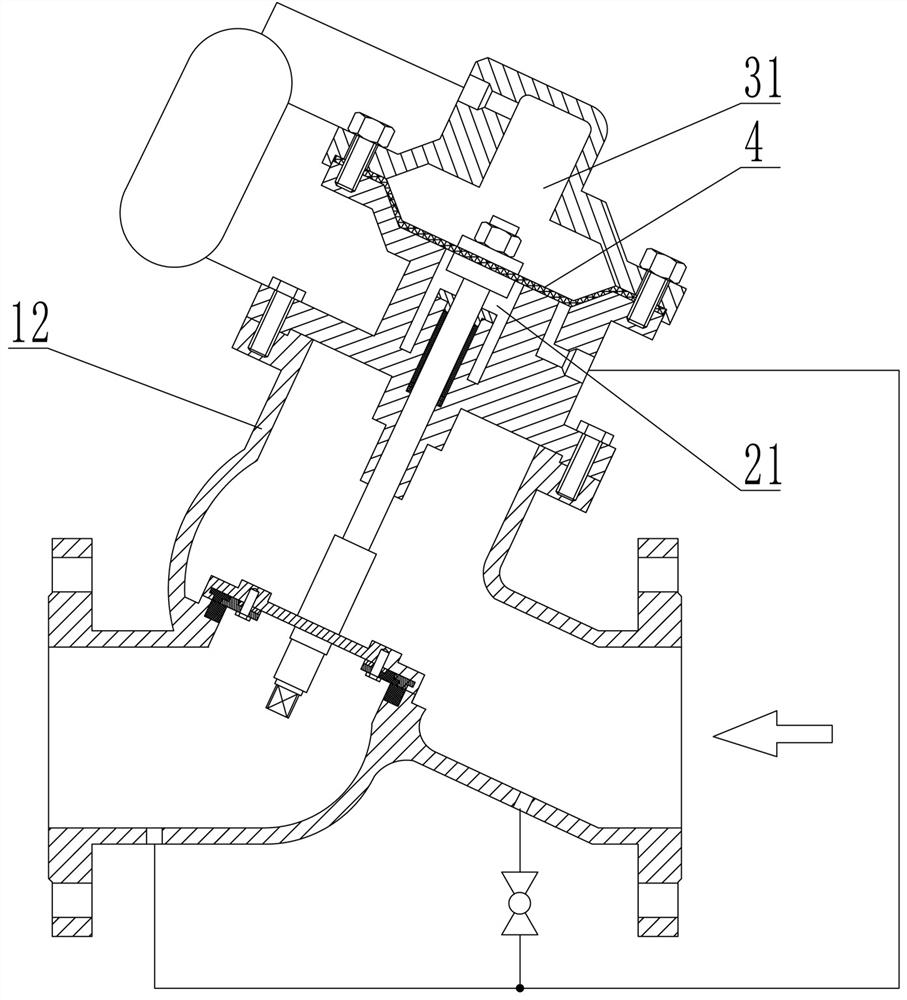

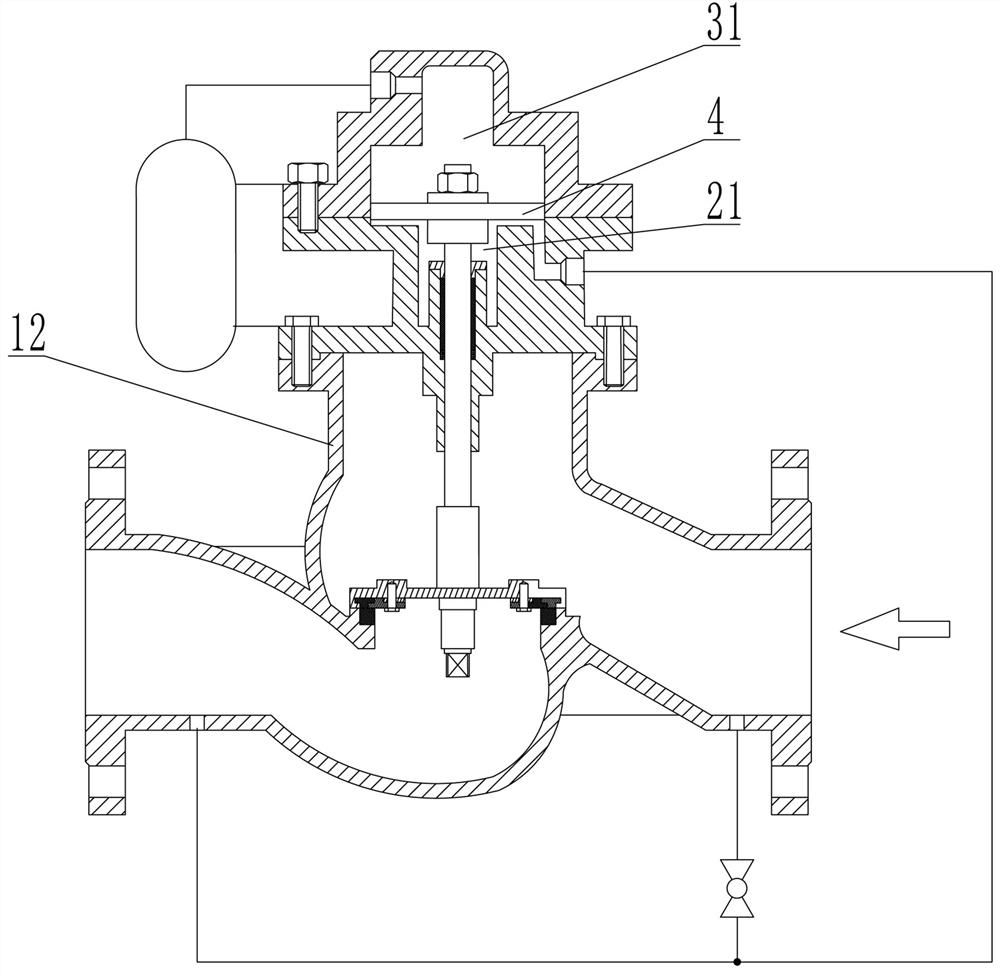

[0054] Such as Figure 1~Figure 4 Among them, a pneumatic squib safety valve, which includes a valve body 1, an end cap 2, an end cap cover 3, a movable part 4, a valve shaft 5, a valve disc 6, a gas cylinder 7 and a communication circuit 8; the end cap 2 The flange surfaces at both ends are respectively connected with the valve body 1 and the end cover cover 3, the valve disc 6 is located in the valve body 1 and contacts the valve seat 13, the valve shaft 5 is slidingly fitted with the end cover 2, and one end of the valve shaft 5 is in contact with the valve disc 6 Connection, the movable part 4 is connected with the other end of the valve shaft 5, the cylinder 7 is communicated with the end cap cover 3, and the communication circuit 8 is communicated with the valve body 1 and the end cap 2. The structure is simple, the branch channel 12 of the valve body 1 is connected to the flange surface on one side of the end cover 2, the flange surface on the other side of the end cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com