Grain spreading and airing device for wine brewing

A grain and casing technology, applied in the direction of drying solid materials, non-progressive dryers, dryers, etc., can solve the problems of unfavorable storage and transportation, inability to store, low efficiency, etc., to improve stability and service life , save storage space and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

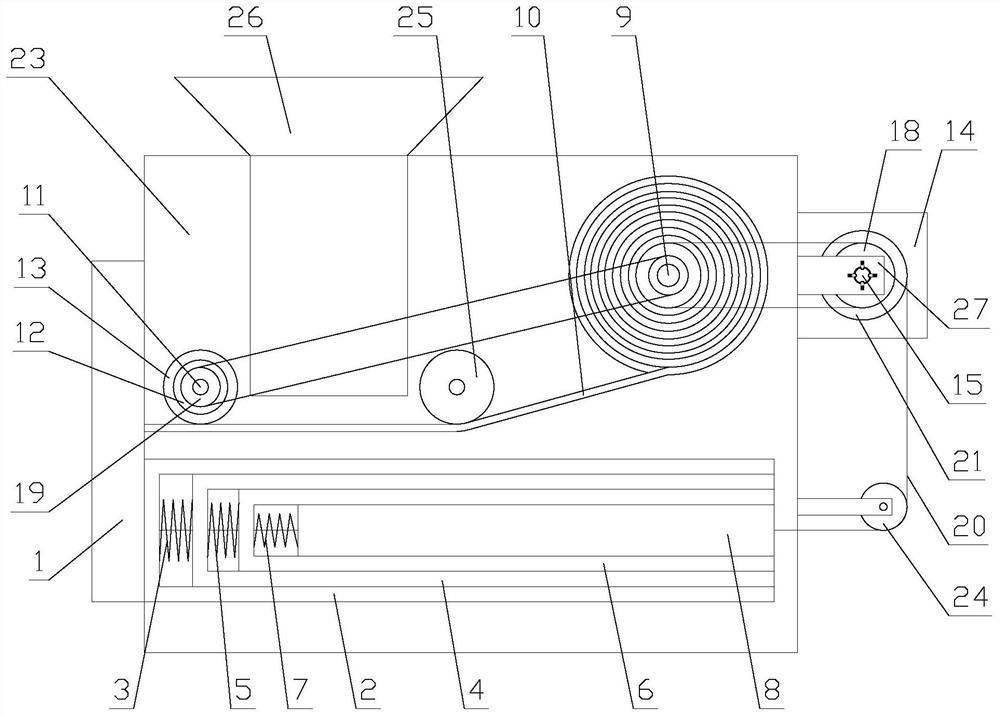

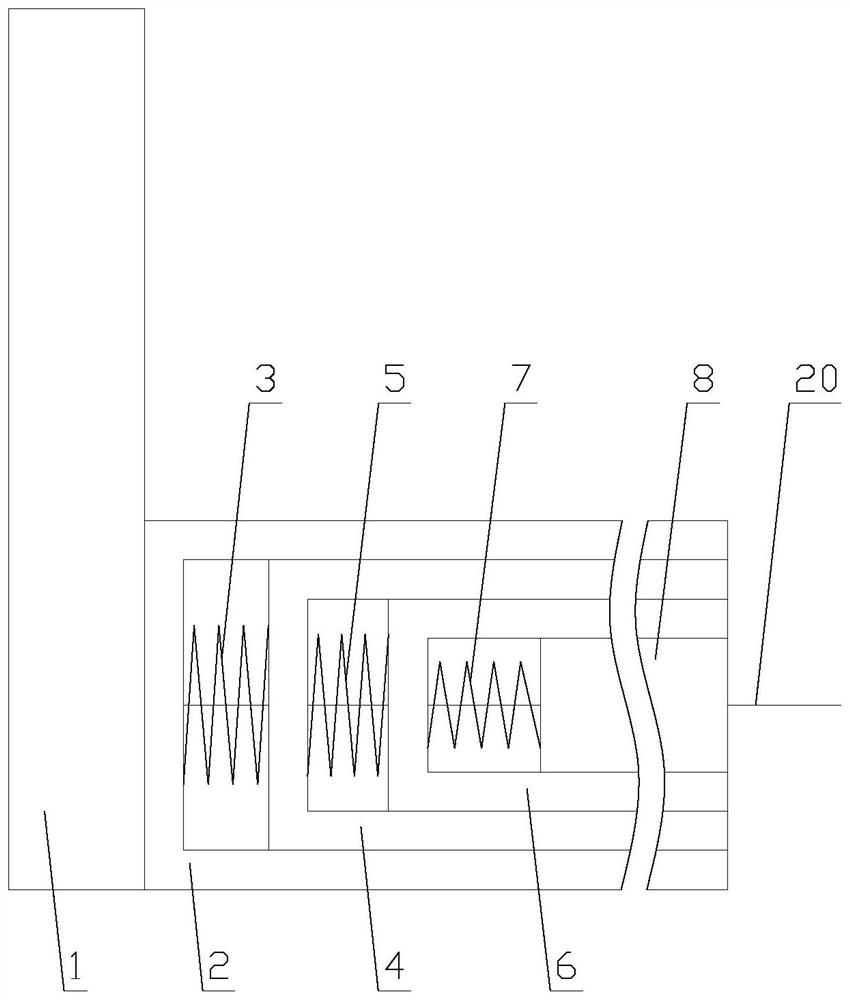

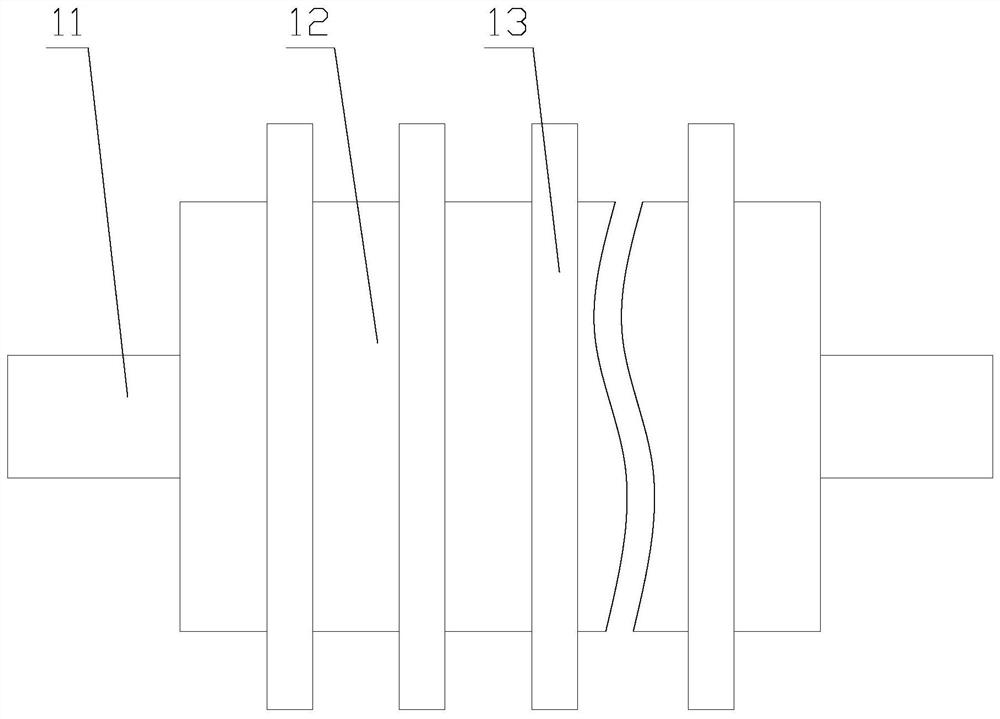

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 As shown, a grain spreading device for wine making includes a bracket, a driving mechanism, a placement mechanism and a paving mechanism, the driving mechanism is arranged on one side of the bracket, the placement mechanism is arranged on the bracket, and the paving mechanism The flat mechanism is set on the placing mechanism;

[0024] The grain for brewing is placed on the placement mechanism, and the grain is paved by the paving mechanism to achieve a better spreading effect.

[0025] Such as figure 2 As shown, the placement mechanism includes a placement assembly and a telescopic assembly, and the telescopic assembly includes a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com