Quartz flotation separation device

A separation device, quartz technology, applied in flotation, solid separation, mixer with rotating stirring device, etc., can solve the problems of inconvenient collection and cleaning of materials, uneven mixing of agents, low utilization rate of agents, etc. Uniform gas distribution, good flotation effect, resource saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

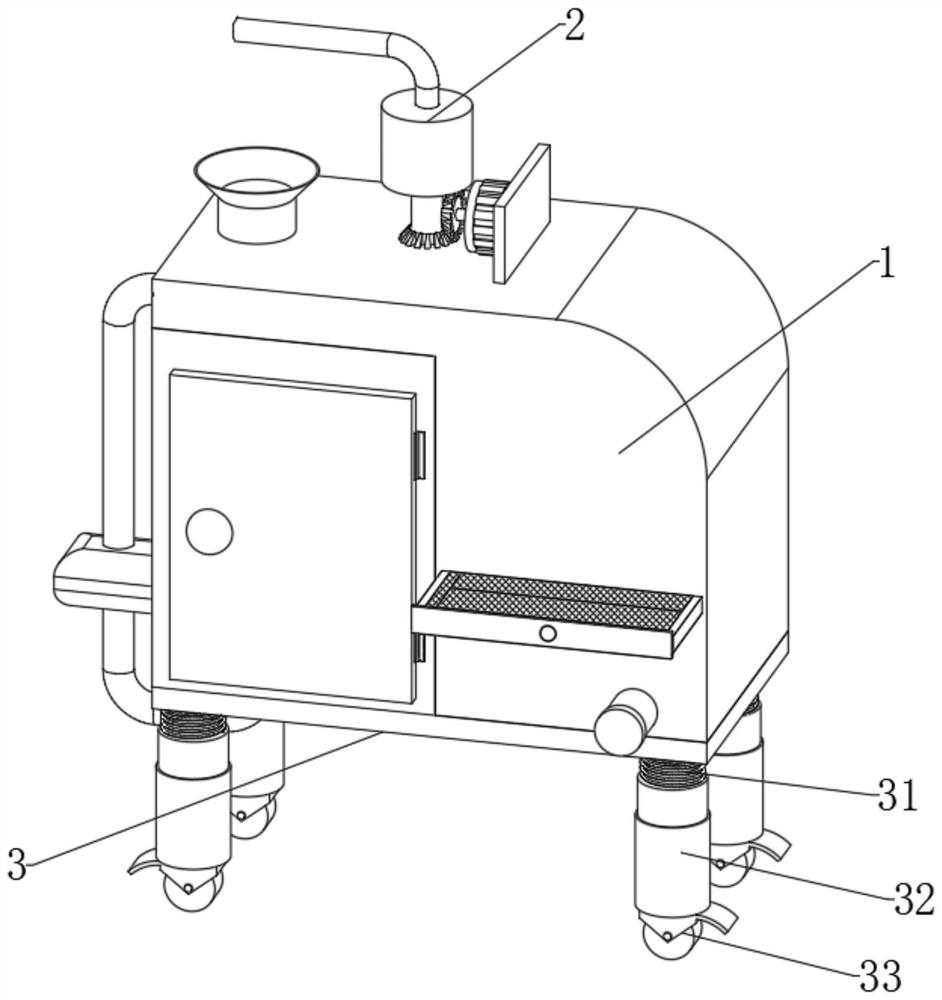

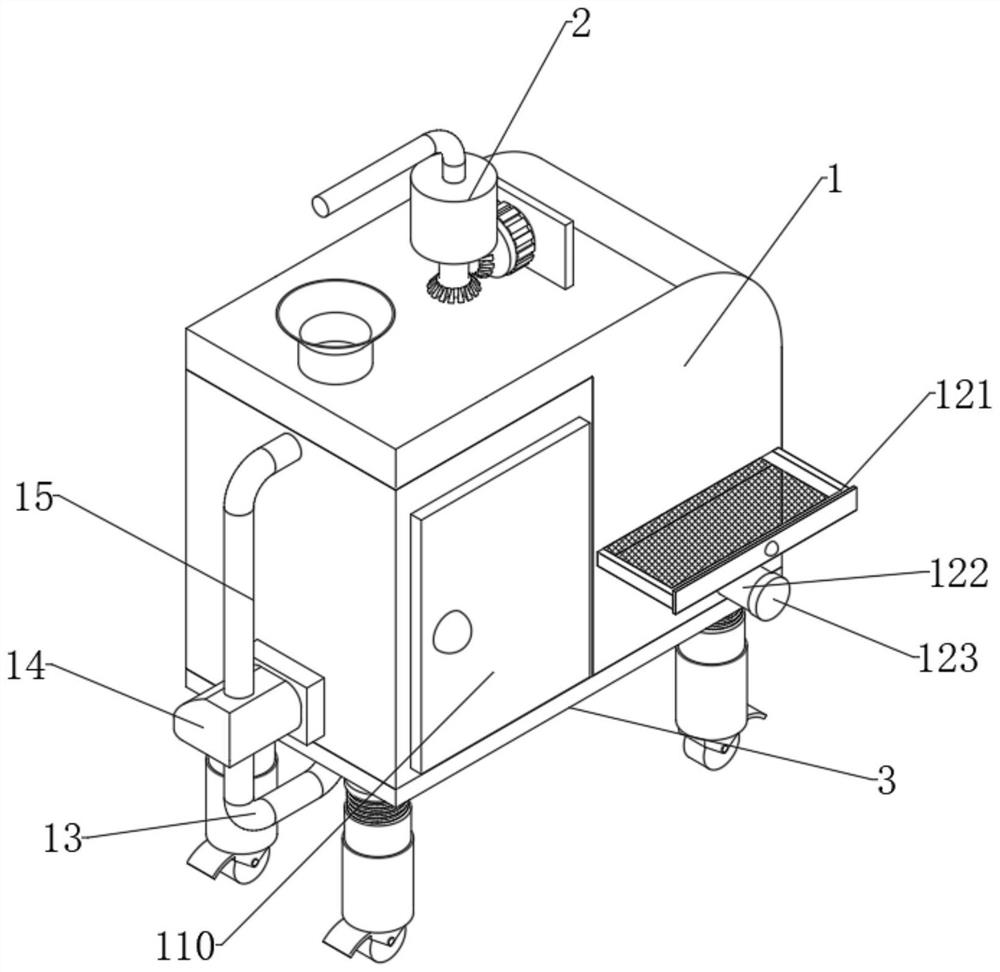

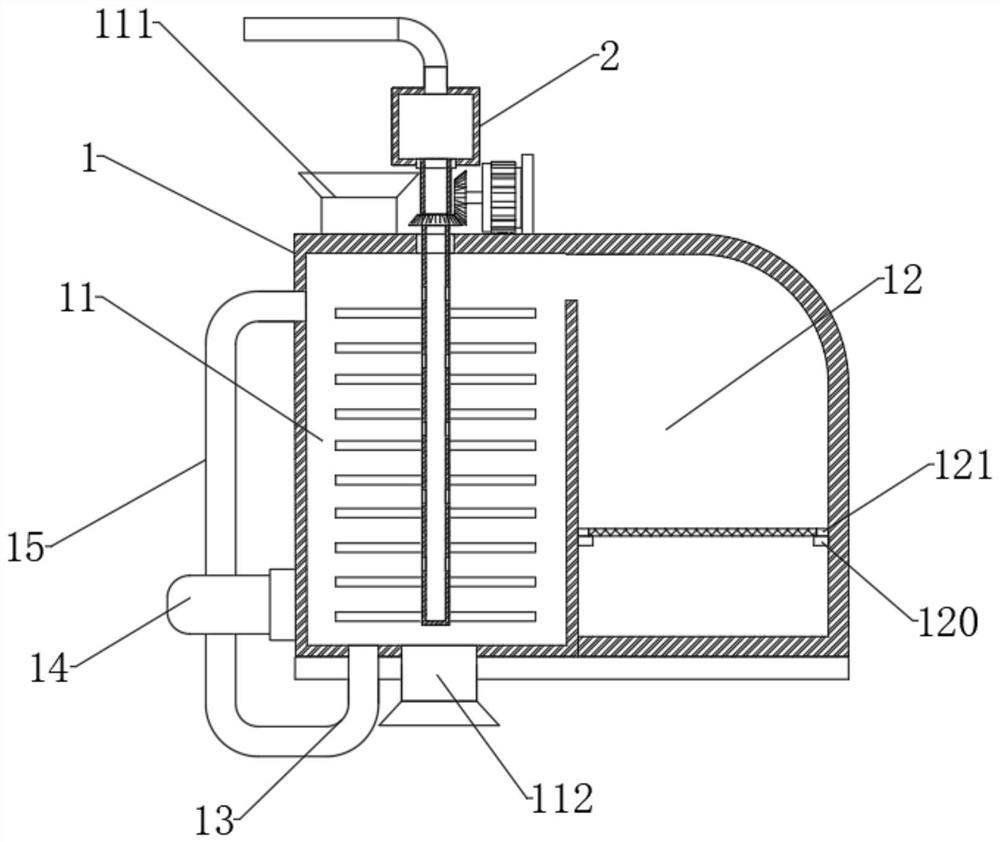

[0024] A quartz flotation separation device, in order to solve the problems of inconvenient collection and cleaning of materials leached by flotation in the existing quartz flotation separation device, uneven mixing of medicaments, low utilization rate of medicaments and poor practicability, as a preferred embodiment ,Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the flotation tank 1 is included, and the inside of the flotation tank 1 is provided with a flotation chamber 11 and an immersion liquid collection chamber 12. Net 121, both side walls of the immersion liquid collection chamber 12 are provided with slide rails 120, the top of the slide rails 120 is slidingly provided with a filter screen 121, the filter screen 121 can filter the flotation leached material inside the flotation chamber 11, and the immersion liquid The lower end of the side wall of the collection chamber 12 is communicated with a liquid outlet 122, and the end of the liquid outlet 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com