Sand core raw material processing equipment with protection function for casting hole of high manganese steel casting

A protection function and technology for processing equipment, applied in casting molding equipment, metal processing equipment, casting molds, etc., can solve the problems of inconvenient cleaning of broken materials, inconvenient automatic feeding work, inconvenient lifting and lowering of molds, etc., to achieve Increase the effect of the protective function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

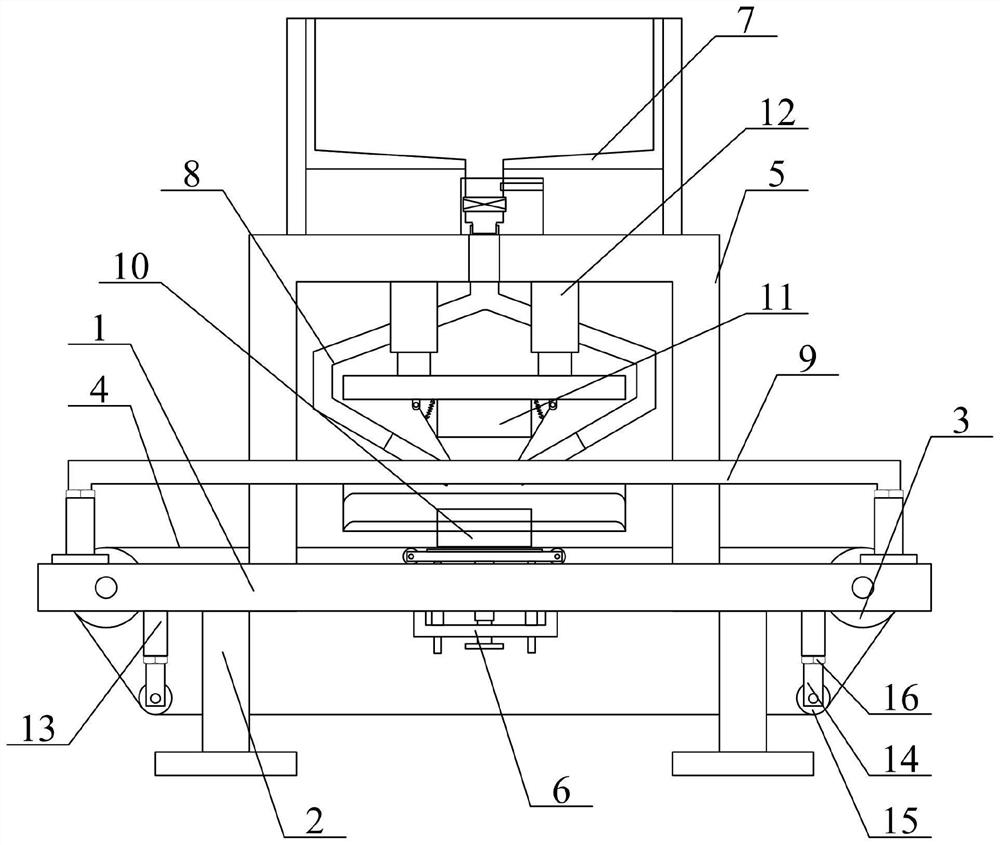

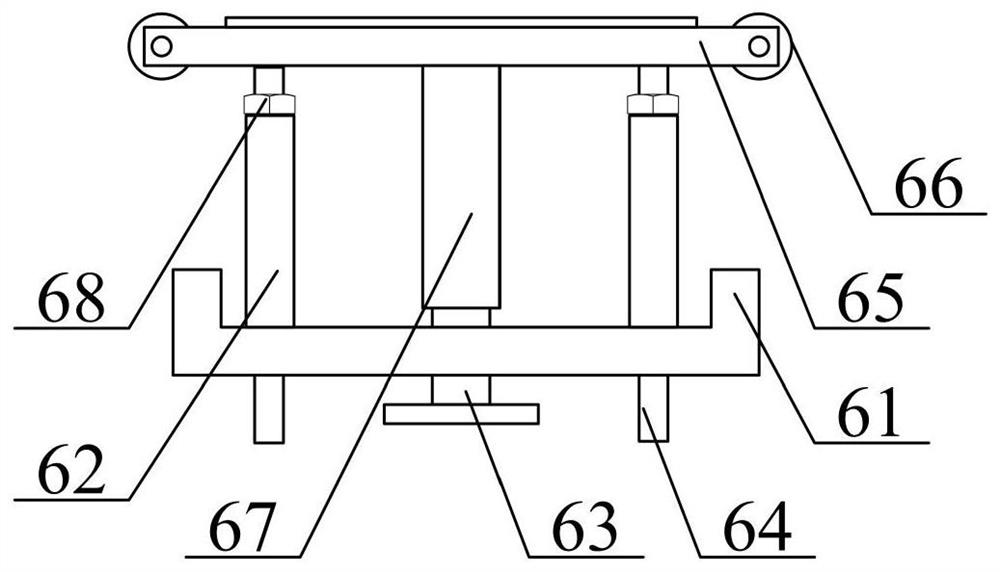

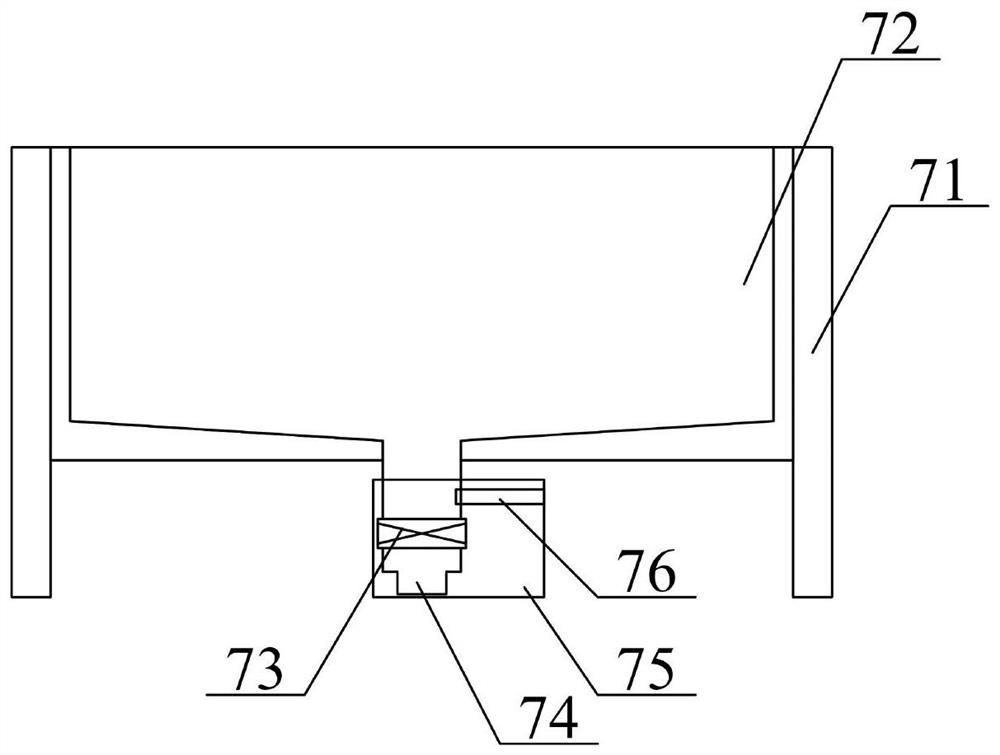

[0036] The present invention will be specifically described in conjunction with the accompanying drawings. figure 1 Attach figure 2 As shown, a sand core material processing apparatus having a protective function of high manganese steel casting is molded, including a first support frame 1, a support leg 2, a conveying support roller 3, a conveyor belt 4, a second support frame 5, and can be supported The stamped housing structure 6, can be fixed to clear the storage box structure 7, can pull the buffer upper tube structure 8, can be lifted away from the protective frame structure 9, the lower mold 10, the upper mold 11, the hydraulic rod 12, the support tube 13, regulating seat 14 The first support roller 15 and the first locking nut 16 are respectively bolted in the lower ends of the first support frame 1, respectively; the conveying support roller 3 is axially connected in the first support frame 1 The intermediate position of the left and right sides and is connected to the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com