Boring device, boring method and stern shaft mounting method

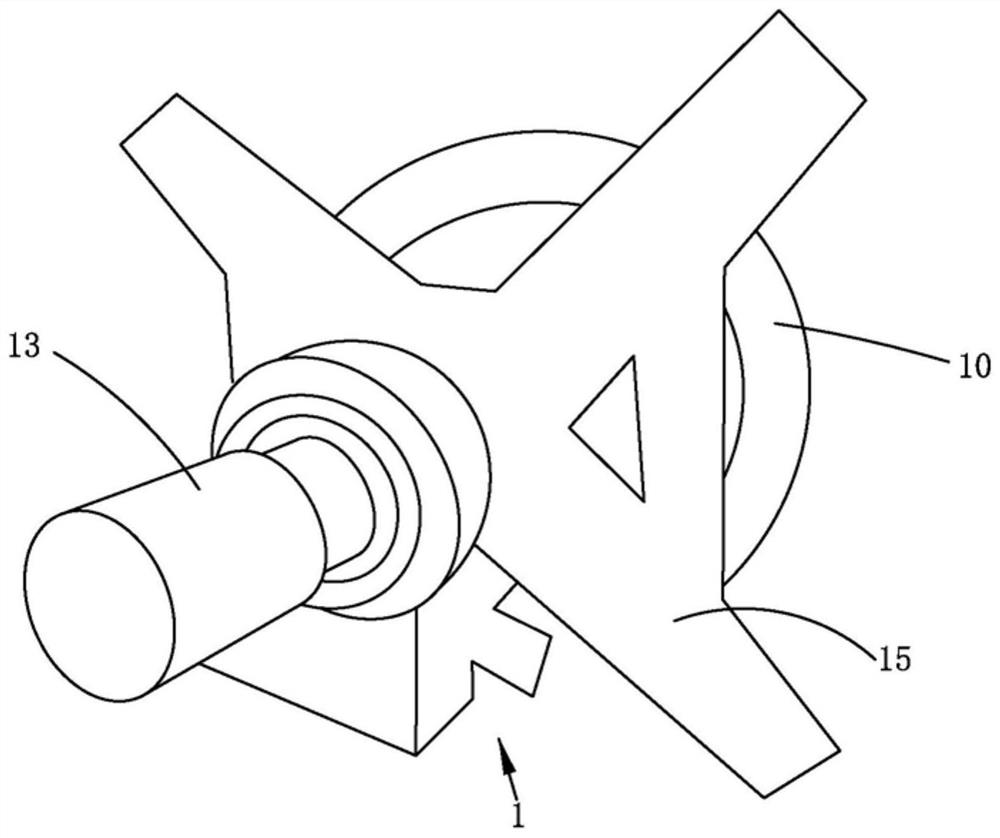

A technology for boring and stern tubes, which is applied in the field of ship shafting installation, can solve the problems of easy bending and deformation of boring rods, poor boring quality, and low precision, and achieve the goals of shortening the construction period, advancing installation time, and improving machining accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

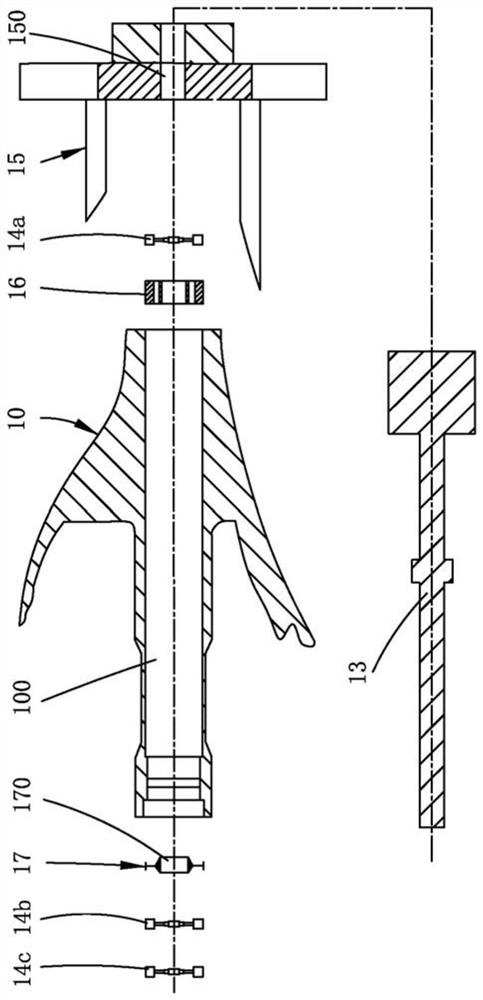

[0097] Please also refer to Figure 8 , the present embodiment provides a boring method S10 for boring the stern tube 10 using the boring device 1, comprising the following steps:

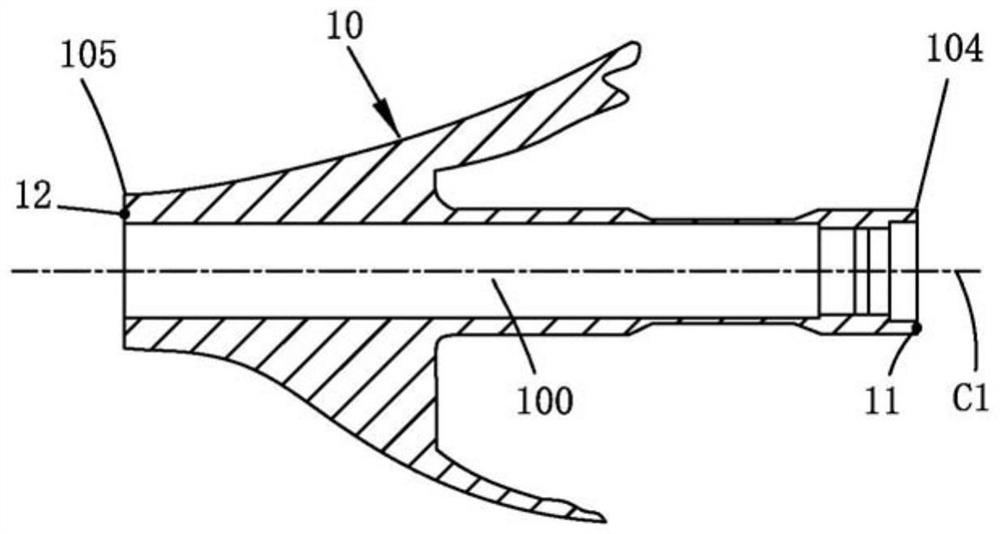

[0098] S100: if image 3 As shown, the light target bow base point 11 and the light target stern base point 12 are set, and the theoretical centerline C1 of the shaft system is determined by lighting. Light targets are respectively set at the light target bow base point 11 and light target stern base point 12, the light target at the light target bow base point 11 and the light target at the light target stern base point 12 are irradiated by the light source, and the line segment passing through the center of the two light targets is the axis system Theoretical centerline C1. After the theoretical centerline C1 of the shaft system is determined, the position and angle of the light source need to be kept fixed so as to be used for subsequent determination of the reference point.

[0099] S101: if...

no. 3 example

[0114] Please also refer to Figure 5 with Figure 12 , the present embodiment provides a stern shaft installation method, using the aforementioned boring device 1, including the following steps:

[0115] S200: Construct the general section of the stern tube.

[0116] S202: Carry out boring by using the boring method S10.

[0117] S203: Press the bearing bush into the fifth through hole 103. Pressing the bearing bushing requires a single press into place. The bearing bush needs to be cooled before pressing the bearing bush, so that the bearing bush forms an interference fit with the fifth through hole 103 during operation. For example, the cooling of the bearing bush can be cooled with liquid nitrogen ice, so that the bearing bush can shrink and then press fit. In order to prevent the bearing bush from being scrapped after installation, the bearing bush is required to be pressed in place at one time. If the bearing bush is not pressed in place or pulled out and tried agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com