Machining fixing table for automobile accessory electronic elements

A technology of electronic components and fixed table, applied in workbench, manufacturing tools, closed-circuit television system, etc., can solve the problems of inability to process, fix the size of the fastening mold, and affect the production of parts, so as to achieve convenient operation, avoid dust entry, operation convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

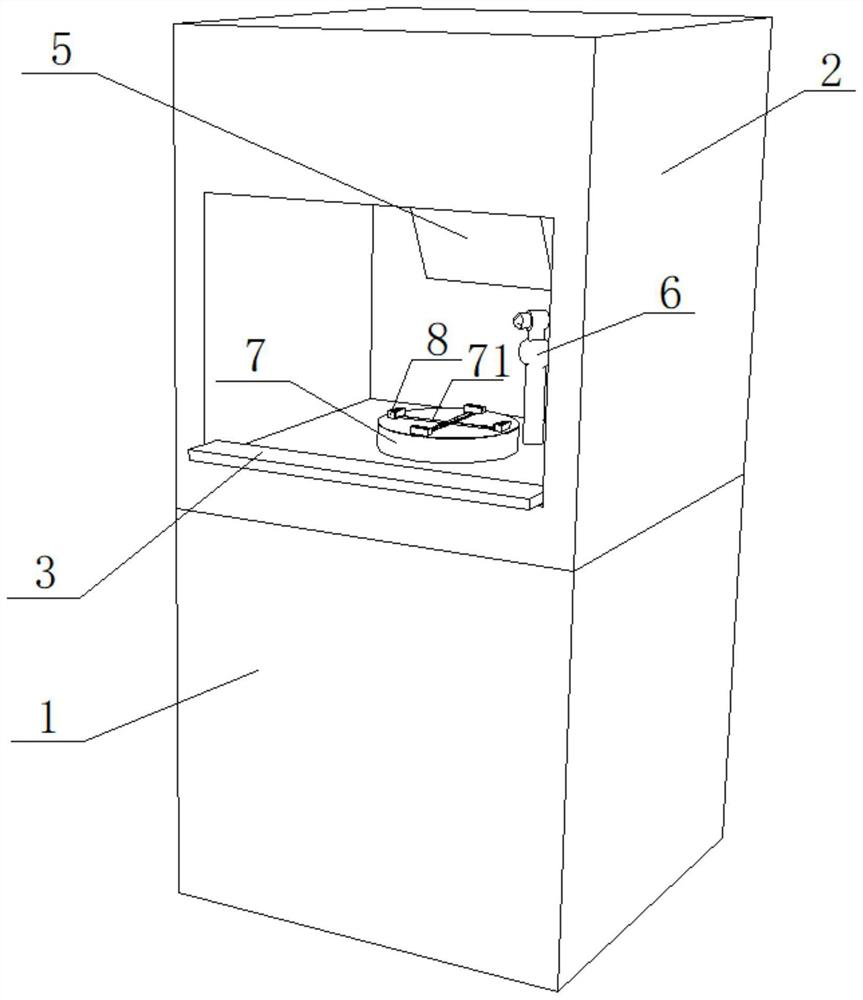

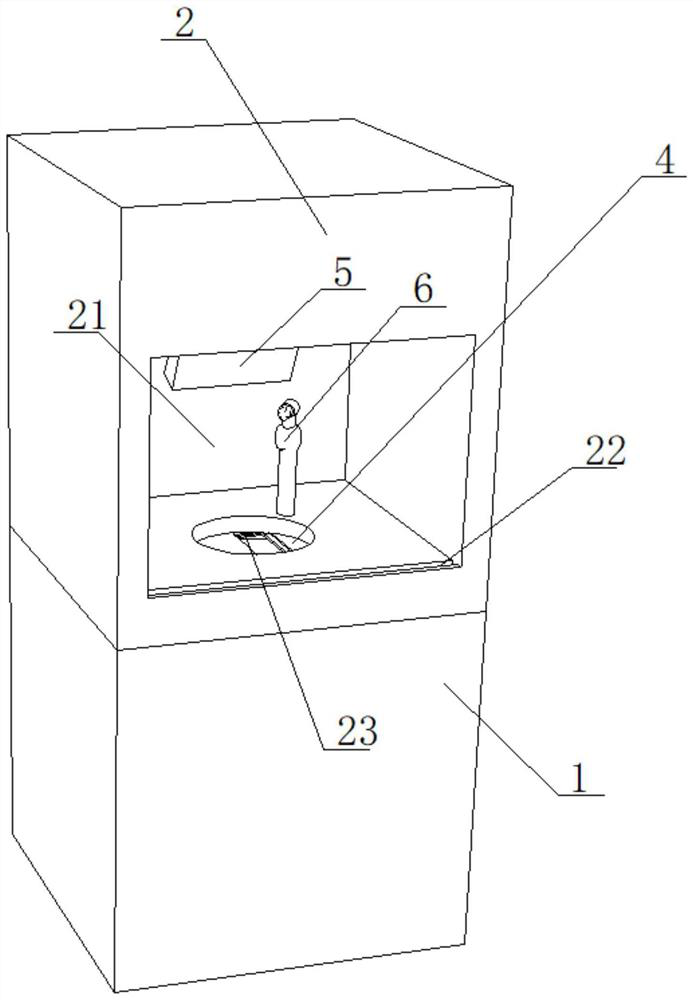

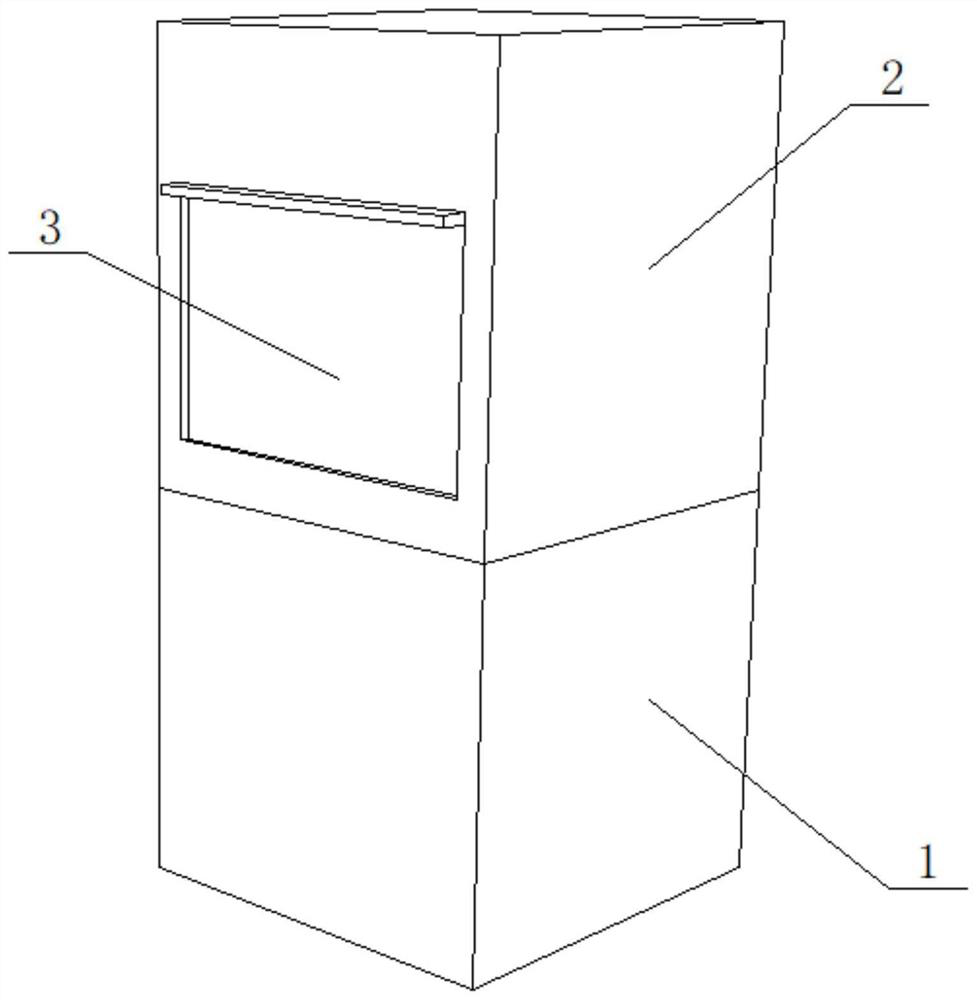

[0039] as attached figure 1 to attach image 3 As shown, the present invention provides a processing and fixing platform for auto parts electronic components, including a base 1 and a processing chamber 2 on the upper part of the base 1, and a working space 21 is provided inside the processing chamber 2, and the front part of the working space 21 is A storage opening 22 is provided on the bottom side, and a closed slide rail 23 is installed in the middle of the processing chamber 2 .

[0040] as attached figure 1 to attach image 3 As shown, in the above embodiment, specifically, the storage opening 22 is nested with a sliding door 3, and the closed slide rail 23 is slidingly connected to the closed door 4 on both sides, and the upper part of the working space 21 is provided with a clockwise Flip the display 5 by 60°.

[0041] as attached figure 1 to attach Figure 4 As shown, in the above embodiment, specifically, a fixed platform 7 is provided on the upper side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com