Molding sand buffering hopper for steel preparation

A technology of buffer bucket and molding sand, applied in the directions of large containers, loading/unloading, conveyors, etc., can solve the problems of adhesion, difficult discharge of molding sand, agglomeration, etc. The effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

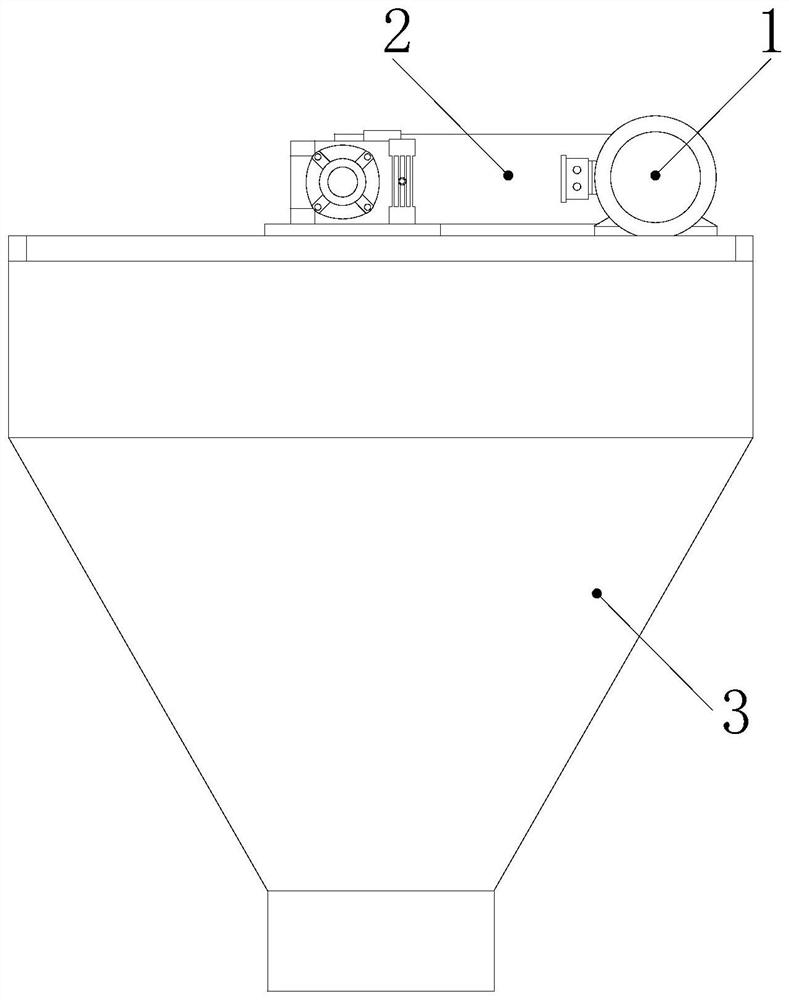

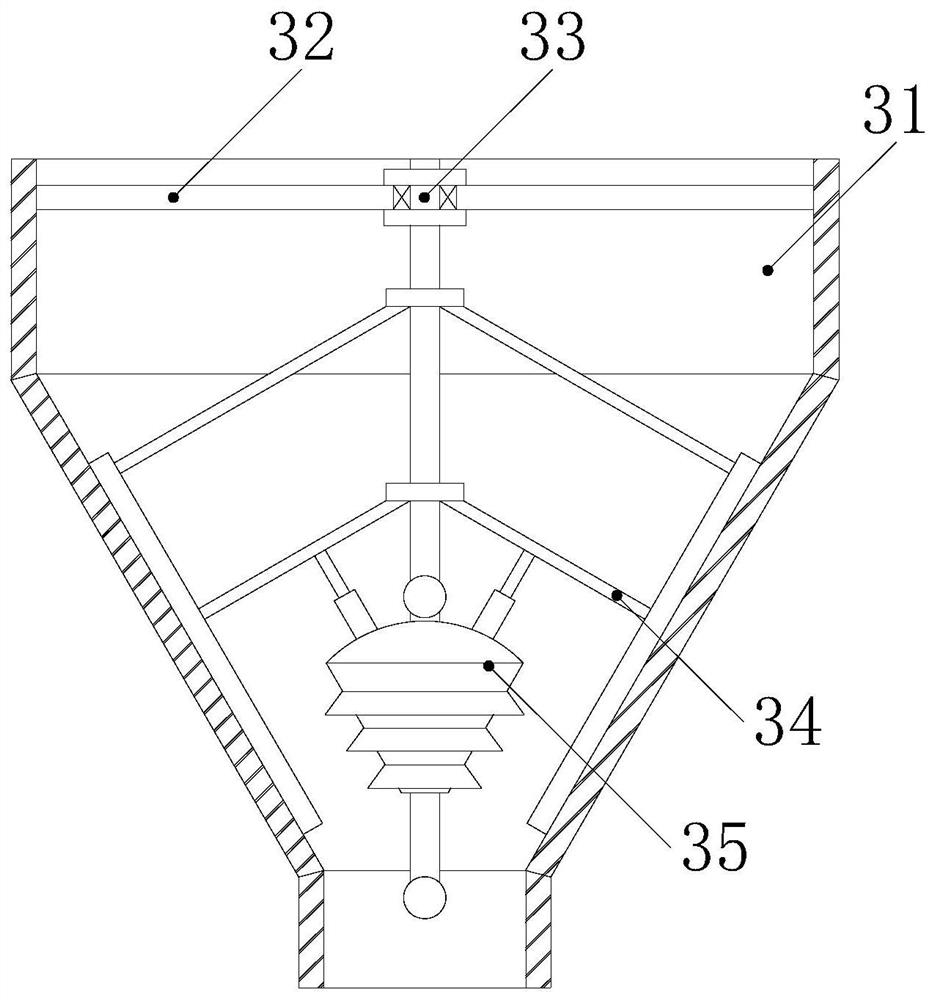

[0022] as attached figure 1 to attach Figure 4 Shown:

[0023] The present invention is a molding sand buffer bucket for steel preparation, its structure includes a motor 1, a dust cover 2, and an anti-blocking hopper 3, the motor 1 is installed at the right end of the dust cover 2, and the bottom of the motor 1 is set on the top of the anti-blocking hopper 3 , the left end of the dust cover 2 is located at the middle end of the top of the anti-blocking hopper 3. The anti-blocking hopper 3 includes a bucket body 31, a support plate 32, a rotating rod 33, a wall-attaching mechanism 34, and a sinking mechanism 35. The bucket body The inner side of the top of 31 is welded with a support plate 32, and the upper surface of the right end of the support plate 32 is fixedly installed with the bottom of the motor 1, and the rotating rod 33 runs through the middle end of the supporting plate 32 through clearance fit, and the rotating rod 33 and the output end of the motor 1 Rotate sy...

Embodiment 2

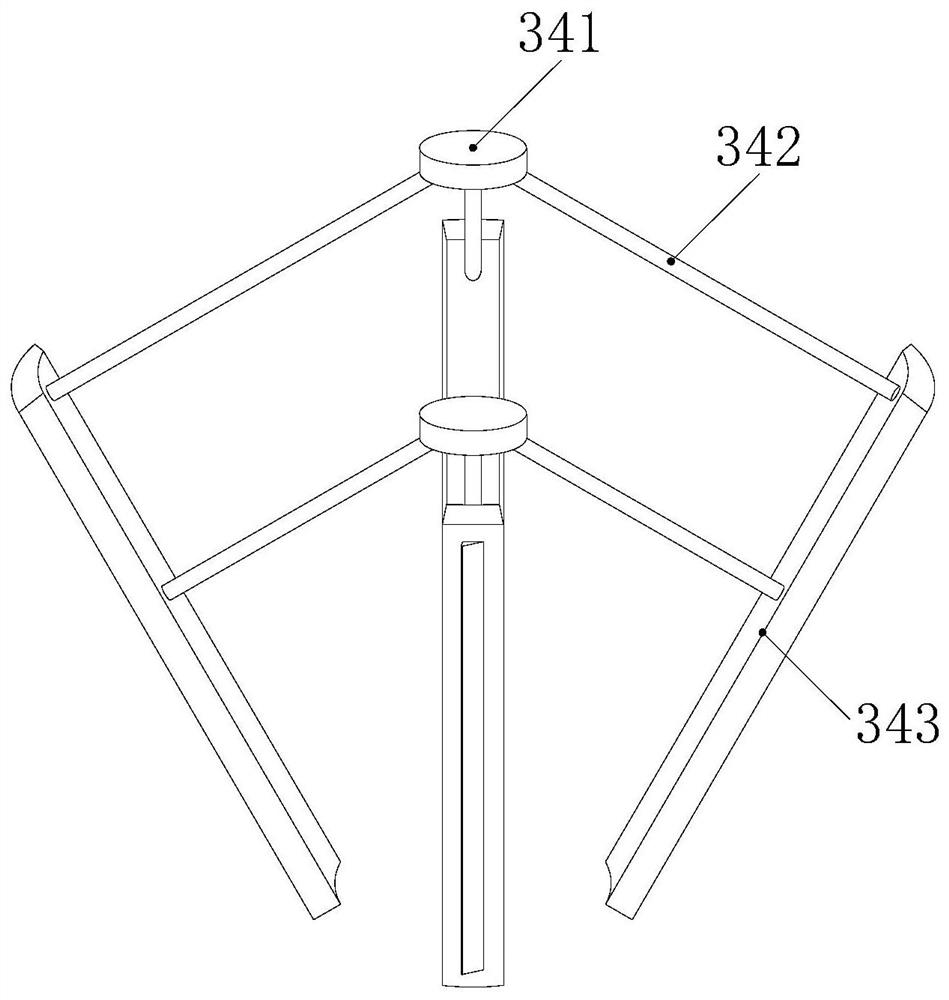

[0029] as attached Figure 5 to attach Figure 7 Shown:

[0030]Wherein, the sinking mechanism 35 includes a guide rod 351, a limit block 352, a push-down mechanism 353, and a slider 354. The top of the guide rod 351 is welded to the lower end of the rotating rod 33, and the limit block 352 is located on the guide rod. 351 lower end, the guide rod 351 runs through the inside of the push-down mechanism 353 using clearance fit, and the top outer end of the push-down mechanism 353 is fixed with the connecting rod 342, the inside of the push-down mechanism 353 is provided with a slider 354, and the slider 354 is slidably installed inside the outer end of the guide rod 351, and the slide block 354 is provided with two in total, which are respectively located at the two ends of the gap between the inner middle end of the push-down mechanism 353 and the guide rod 351, so as to ensure that the push-down mechanism 353 is in the guide Steadily slide up and down on the rod 351, the sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com