A kind of copper-containing sludge sintering method

A sintering method and technology of copper sludge, which is applied in the field of copper-containing sludge sintering, can solve the problems of low oxygen utilization rate, increase energy consumption, and reduce sintering agglomeration rate, so as to improve oxygen utilization rate and eliminate undercrowding or over-burning , the effect of increasing the sintering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

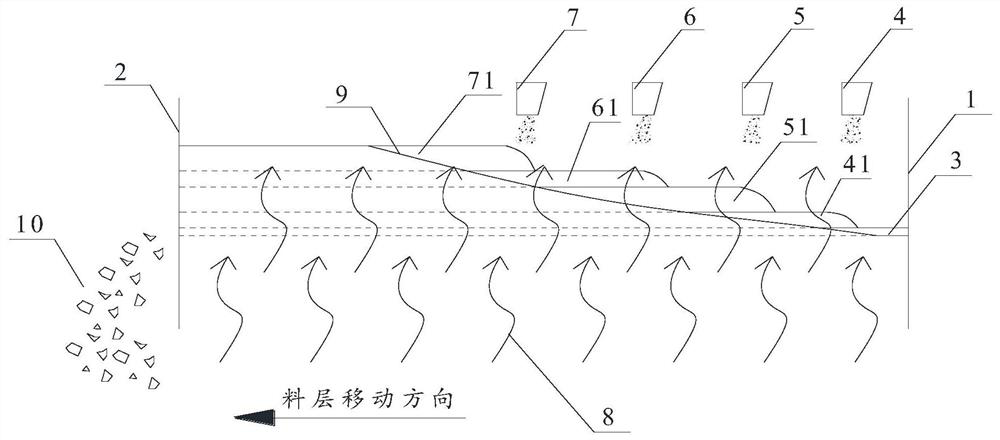

[0055] In the present invention, four feeding points are respectively set along the direction from the first end 1 to the second end 2, and the materials to be sintered are sequentially added in 4 times, and 4 feeding layers are formed; namely, the first feeding point 4 and the first material layer 41 , the second feeding point 5, the second feeding layer 51, the third feeding layer 6, the third feeding layer 61 and the fourth feeding point 7, the fourth feeding layer 71; the first feeding point 4 is 2m away from the first end 1 , the second feed point 5 is 4m from the first feed point 4, the third feed point 6 is 4m from the second feed point 5, and the fourth feed point 7 is 4m from the third feed point 6. Further, the number of feedings is determined according to the actual situation, and the longer the distance between the first end portion 1 and the second end portion 2, the more feeding times can be set. The distance between the feeding points is determined according to ...

Embodiment

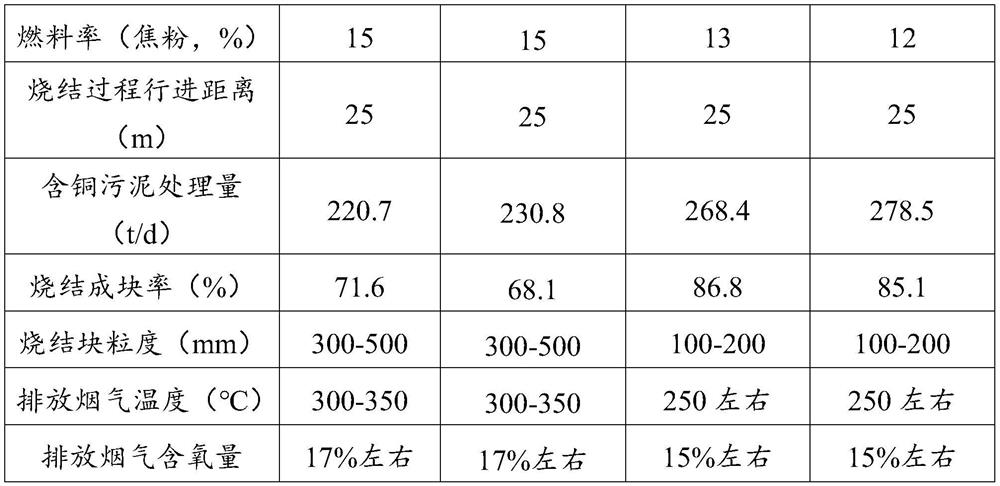

[0060] The results of using the sintering method of the present invention and the existing sintering method are compared as shown in Table 1:

[0061] Table 1

[0062]

[0063]

[0064] The advantages of the present invention are:

[0065] 1. The present invention treats the sintered material (mixture of copper-containing sludge and fuel) to carry out cloth sintering by means of graded and layered cloth, rather than traditional disposable cloth sintering; that is, the primer layer is first ignited, and then the For the first cloth, because the first material layer is thin and has good air permeability, the heat moves up quickly, and the copper-containing sludge is dried, dehydrated and sintered very quickly; when the first material layer has been fully ignited, the second The second cloth is the same as the first cloth, and the drying, dehydration and sintering process of the second material layer is also very fast, and then the subsequent multiple cloths are performed;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com