Environment-friendly dry-method framework cloth and preparation process thereof

A production process and technology of skeleton cloth, applied in the field of environmentally friendly dry skeleton cloth and its production process, can solve the problems of increased gram weight, general hardness, poor uniformity, etc., to ensure the consistency of appearance, hardness and strength. , the effect of good hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

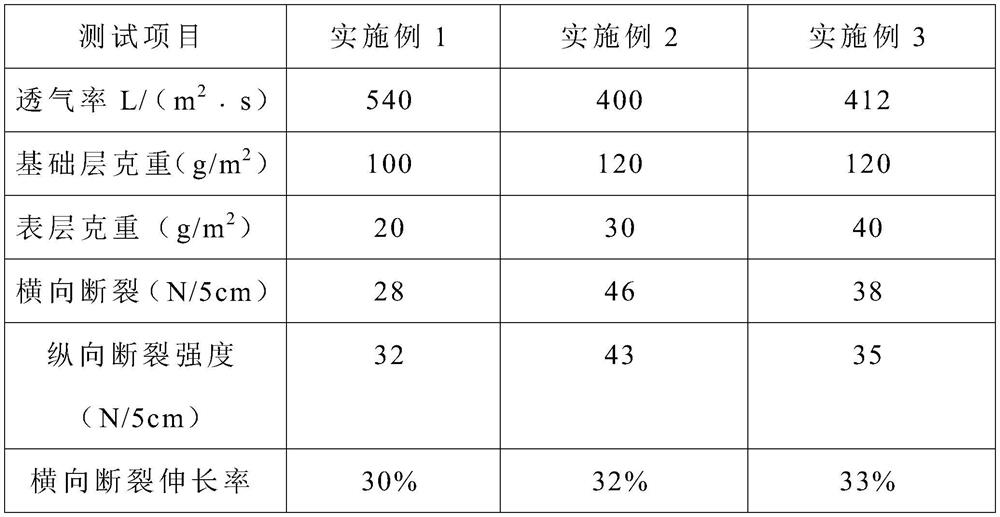

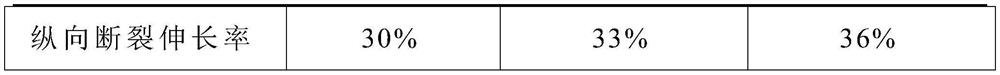

Embodiment 1

[0032] Embodiment 1: a kind of manufacturing process of environment-friendly dry-laid skeleton cloth, comprises the following steps:

[0033] (1) Select fibers: select fibers with a crimp rate no more than 10% as the first fiber, and select fibers with a crimp rate ≥ 10% as the second fiber; the linear density of the first fiber is 0.5dtex, and the length is 25mm;

[0034] (2) Coarse opening: using opening equipment, the first fiber is initially opened as the base layer fiber material; the first fiber and the second fiber are opened and fully mixed at a mixing ratio of 2:1 to obtain the surface layer web material;

[0035] (3) Fine opening: control the fed fibers to be uniform and soft, and finely open the base layer fiber material and the surface layer fiber web material respectively;

[0036] (4) The fiber material of the base layer is air-laid to obtain a grammage of 100g / m 2 , a base layer fiber web with a thickness of 2mm; then the surface layer fiber web material is ai...

Embodiment 2

[0039] Embodiment 2: a kind of manufacturing process of environment-friendly dry-laid skeleton cloth, comprises the following steps:

[0040] (1) Select fibers: select fibers with a crimp rate no more than 10% as the first fiber, and select fibers with a crimp rate ≥ 10% as the second fiber; the linear density of the first fiber and the second fiber is 4dtex, and the length is 30mm;

[0041] (2) Coarse opening: using opening equipment, the first fiber is initially opened as the base layer fiber material; the first fiber and the second fiber are opened and fully mixed at a mixing ratio of 3:1 to obtain the surface layer web material;

[0042] (3) Fine opening: control the fed fibers to be uniform and soft, and finely open the base layer fiber material and the surface layer fiber web material respectively;

[0043] (4) The fiber material of the base layer is air-laid to obtain a grammage of 110g / m 2 , a base layer fiber web with a thickness of 5mm; then the surface layer fiber...

Embodiment 3

[0046] Embodiment 3: a kind of manufacturing process of environment-friendly dry-laid skeleton cloth, comprises the following steps:

[0047] (1) Select fibers: choose fibers with a crimp rate no more than 10% as the first fiber, and choose fibers with a crimp rate ≥ 10% as the second fiber; the linear density of the first fiber and the second fiber is 8dtex, and the length is 60mm;

[0048] (2) Coarse opening: using opening equipment, the first fiber is initially opened as the base layer fiber material; the first fiber and the second fiber are opened and fully mixed at a mixing ratio of 5:1 to obtain the surface layer web material;

[0049](3) Fine opening: control the fed fibers to be uniform and soft, and finely open the base layer fiber material and the surface layer fiber web material respectively;

[0050] (4) The fiber material of the base layer is air-laid to obtain a grammage of 120g / m 2 , a base layer fiber web with a thickness of 10mm; then the surface layer fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com