Modified aluminum profile with good anti-corrosion effect and preparation method of modified aluminum profile

An anti-corrosion effect, aluminum profile technology, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of general corrosion resistance and wear resistance, insufficient stability, hardness and strength improvement, etc. Achieve the effect of good hardness and strength, stable internal performance, and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

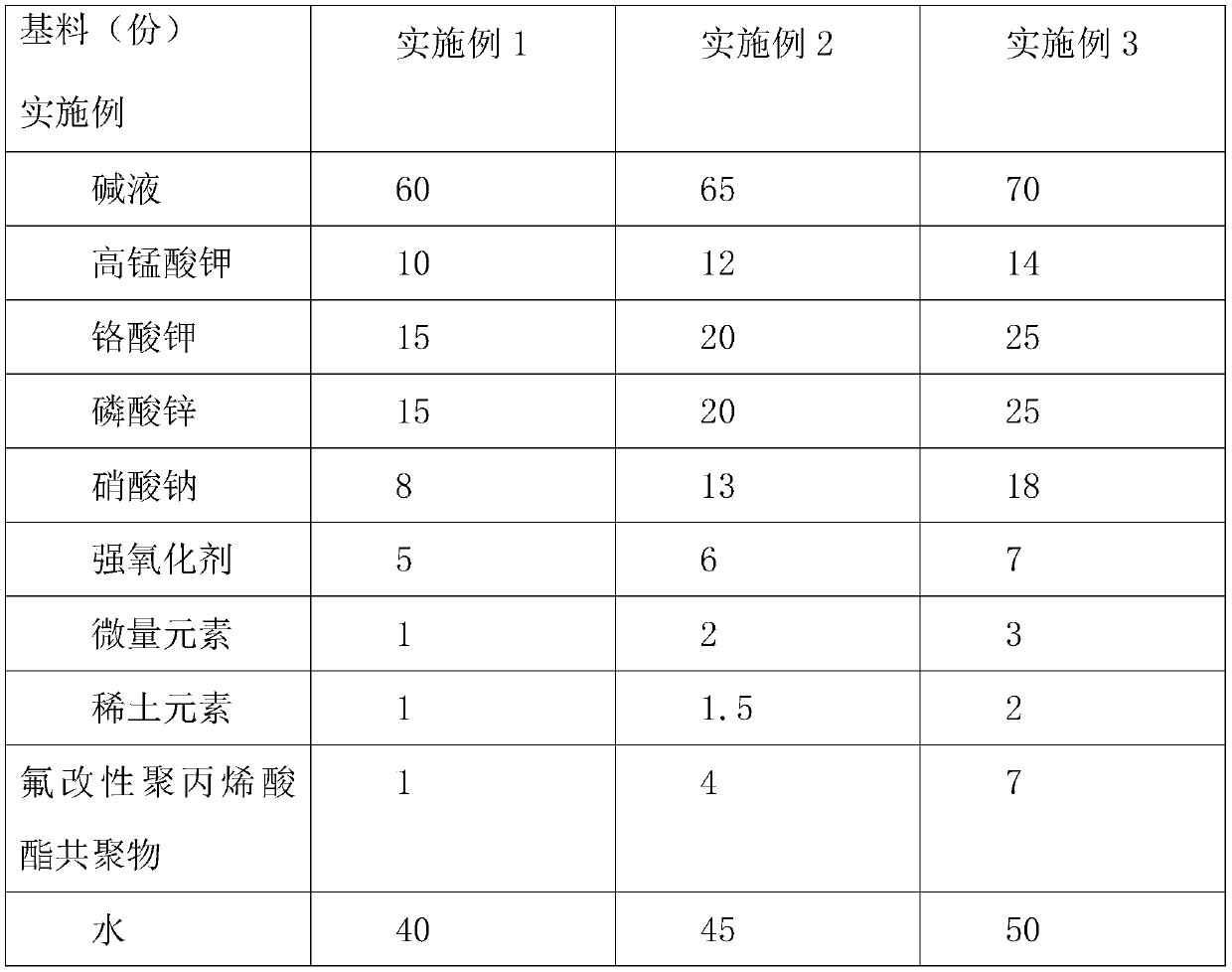

[0025] A modified aluminum profile with good anti-corrosion effect, including the aluminum profile itself and aluminum profile anti-corrosion auxiliary materials, wherein the aluminum anti-corrosion auxiliary materials are weighed in parts by mass as follows: 60 parts of lye, 10 parts of potassium permanganate, 15 parts of potassium chromate parts, 15 parts of zinc phosphate, 8 parts of sodium nitrate, 5 parts of strong oxidizing agent, 1 part of trace element, 1 part of rare earth element, 1 part of fluorine-modified polyacrylate copolymer, 40 parts of water, and the strong oxidizing agent is peroxide Any one of hydrogen, potassium permanganate and hydrogen sulfide, the trace element is a mixture of Ti, Si and Zr, wherein the mass fraction ratio of the Ti, Si and Zr elements is 2:1:1, so The total content of lanthanum and neodymium in the above rare earth elements accounts for more than 30%.

[0026] The present invention also provides a method for preparing a modified alumin...

Embodiment 2

[0036] A modified aluminum profile with good anti-corrosion effect, including the aluminum profile itself and aluminum profile anti-corrosion auxiliary materials, wherein the aluminum anti-corrosion auxiliary materials are weighed in parts by mass as follows: 65 parts of lye, 12 parts of potassium permanganate, 20 parts of potassium chromate 20 parts of zinc phosphate, 13 parts of sodium nitrate, 6 parts of strong oxidizing agent, 2 parts of trace elements, 1.5 parts of rare earth elements, 4 parts of fluorine-modified polyacrylate copolymer, 45 parts of water, and the strong oxidizing agent is hydrogen peroxide Any one of , potassium permanganate and hydrogen sulfide, the trace element is a mixture of Ti, Si and Zr, wherein the mass fraction ratio of the Ti, Si and Zr elements is 2:1:1, the The total content of lanthanum and neodymium in rare earth elements accounts for more than 30%.

[0037] The present invention also provides a method for preparing a modified aluminum prof...

Embodiment 3

[0047]A modified aluminum profile with good anti-corrosion effect, including the aluminum profile itself and aluminum profile anti-corrosion auxiliary materials, wherein the aluminum anti-corrosion auxiliary materials are weighed in parts by mass as follows: 70 parts of lye, 14 parts of potassium permanganate, 25 parts of potassium chromate 25 parts of zinc phosphate, 18 parts of sodium nitrate, 7 parts of strong oxidizing agent, 3 parts of trace elements, 2 parts of rare earth elements, 7 parts of fluorine-modified polyacrylate copolymer, 50 parts of water, and the strong oxidizing agent is hydrogen peroxide Any one of , potassium permanganate and hydrogen sulfide, the trace element is a mixture of Ti, Si and Zr, wherein the mass fraction ratio of the Ti, Si and Zr elements is 2:1:1, the The total content of lanthanum and neodymium in rare earth elements accounts for more than 30%.

[0048] The present invention also provides a method for preparing a modified aluminum profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com