Controllable energy consumption swing column foot

A technology for swinging columns and column bases, which can be used in building components, earthquake resistance, building types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

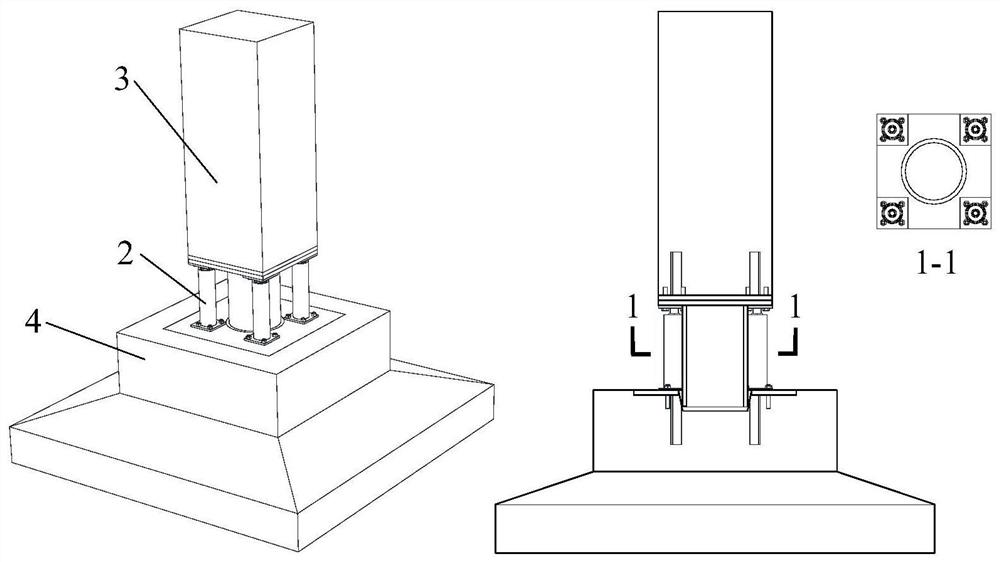

[0029] like figure 1 As shown, the controllable energy-dissipating plastic hinge of the present invention includes a conversion head 1 , a disc spring self-resetting anti-buckling energy-dissipating device 2 , a reinforced concrete column 3 , and a cup base 4 .

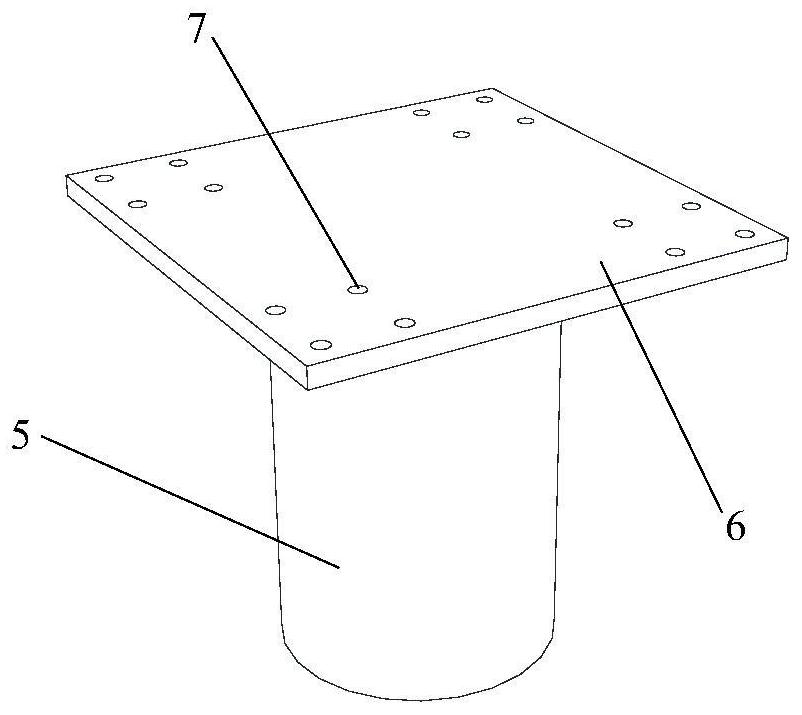

[0030] like figure 2 As shown, the conversion head 1 is composed of a connecting plate 6 (steel plate) and a steel pipe concrete column 5, pouring concrete in the steel pipe, and welding the connecting plate 6 and one end of the steel pipe. Equal-strength design is carried out for steel tube concrete columns and reinforced concrete, and the axial compression ratio is controlled to provide installation space for disc spring self-resetting anti-buckling energy-dissipating devices. Bolt holes 7 are provided on the connecting plate 6 so as to be connected with the pre-embedded bolts 18 on the reinforc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com