Separation type damping stair

A separate and stair technology, applied in the direction of anti-seismic, stepped structure, building components, etc., can solve the problems of not changing the structural failure mode, not meeting earthquake resistance, etc., to avoid adverse effects, simple construction, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

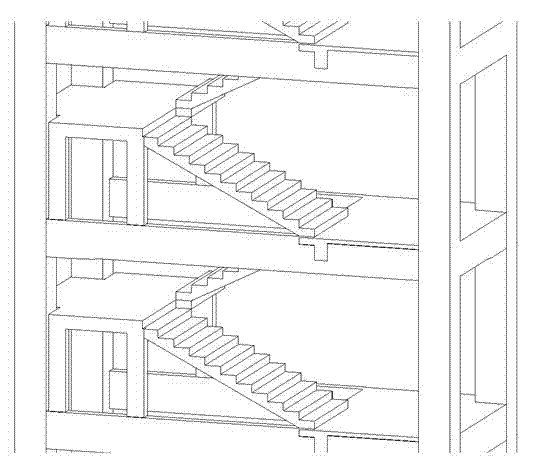

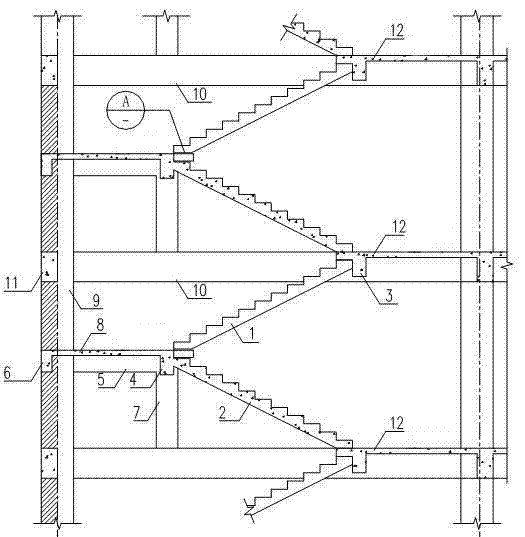

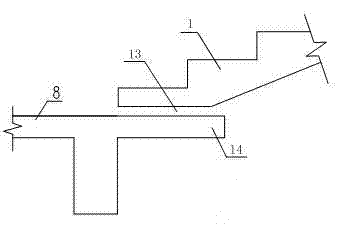

[0037] Embodiment 1: Take two running stairs as an example, such as figure 1 , 2Shown in and 3, a kind of separable damping type staircase is made up of ladder beams 3, 4, 5, 6, ladder columns 7, ladder plates 1, 2 and stair rest platform 8, and described ladder plates 1, 2 and the staircase The rest platform 8 is fixed in the frame structure formed by the frame column 9 and the frame beams 10, 11 through the ladder column 7 and the ladder beams 3, 4, 5, 6, and the ladder plate is composed of the upper ladder plate 1 and the lower ladder plate 2, On the ladder beam 4, a cast-in-place supporting plate A14 is arranged at the corresponding position of the lower end of the upper ladder plate 1, and the upper end face of the cast-in-place supporting plate A14 is on the same level as the upper end face of the stair rest platform 8, and the upper end of the upper ladder A horizontal separation layer 13 with sufficient sliding space is provided between the lower end of the plate 1 an...

Embodiment 2

[0039] Embodiment 2: as Figure 4 and 5 As shown, while having the structure described in Embodiment 1, a cast-in-place supporting plate B18 is arranged at the lower end corresponding to the upper and lower ladder plates 2 of the ladder beam 3, and the upper end surface of the cast-in-place supporting plate B18 is in line with the The upper end surface of the floor 12 is on the same level, and a horizontal separation layer 15 with sufficient sliding space is provided between the lower end of the lower step 2 and the cast-in-place pallet B18, that is, between the lower staircase and the floor. A horizontal separation layer is provided, and the thickness of the section of the horizontal separation layer 15 is 1-20mm, and the width is the same as that of the step board.

[0040] like Figure 11 As shown, at the horizontal separation layer 15 between the lower stairway 2 and the floor 12, a flexible component with a slippage damping function is pre-embedded during construction, ...

Embodiment 3

[0041] Embodiment 3: as Image 6 and 7 As shown, while having the structure described in Embodiment 1, a horizontal separation layer 16 with sufficient sliding space is provided between the stair rest platform 8 and the ladder beam 6, and the thickness of the cross section of the horizontal separation layer 16 is It is 1-20mm, and the width is the same width as the stair rest platform.

[0042] like Figure 12 As shown, at the horizontal separation layer 16 between the stair rest platform 8 and the frame beam 6, a flexible part with a slip damping function is pre-embedded during construction, and the flexible part is a polytetrafluoroethylene film or Cement mortar cushion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com