Control method for oil return and noise reduction of multi-split air conditioner, storage medium and multi-split air conditioner

A control method and multi-connection technology, which are applied in noise suppression, control input involving air characteristics, refrigeration and liquefaction, etc., can solve problems such as loud airflow in refrigeration operation, shorten time, improve user satisfaction, and user experience. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

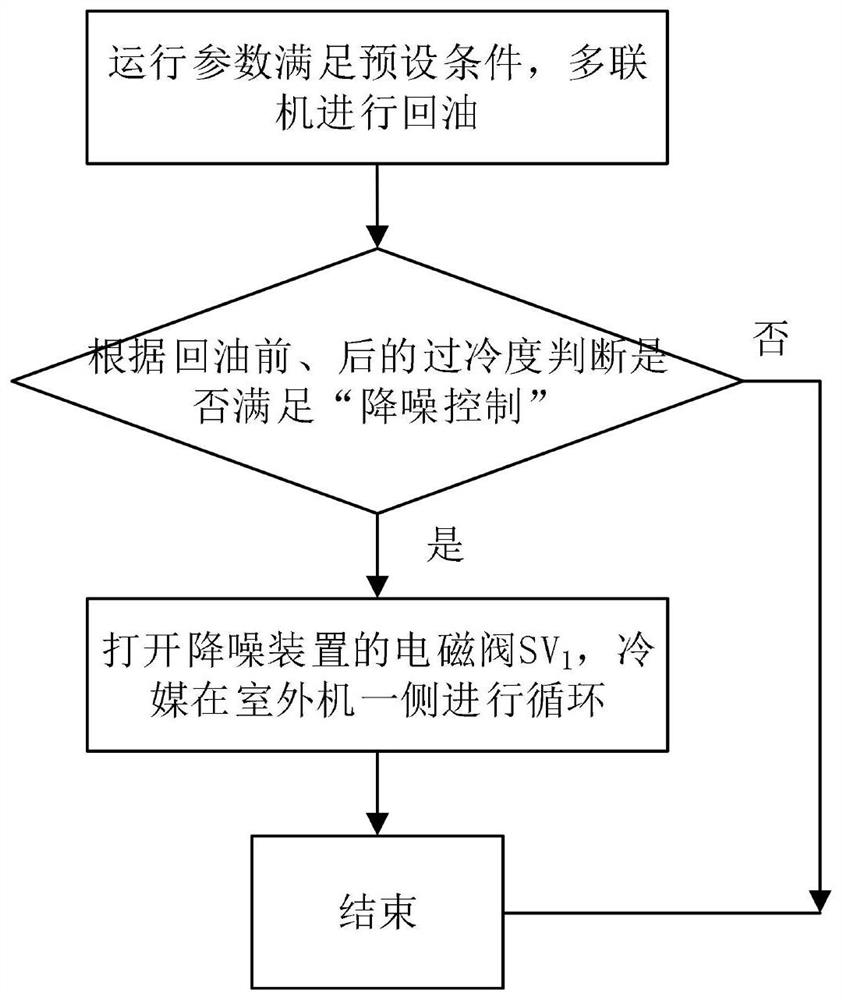

[0031] like figure 1 As shown, a control method for oil return and noise reduction of multi-connected units, the multi-connected units include an outdoor unit and a plurality of indoor units, some of the plurality of indoor units are in the normal power-on state, and the other part is in the standby or power-off state, so The oil return noise reduction control method includes: it is characterized in that the oil return control method includes the following steps:

[0032] S1: When the operating parameters of the multi-line unit meet the preset conditions, the oil return operation is performed;

[0033] After the multi-connector enters the cooling or dehumidification mode, it continuously obtains the indoor ambient temperature T ai , Outdoor ambient temperature T ao , every Δt 0 Get Exhaust High Pressure P d1 , Suction low pressure P s1 , the high pressure corresponds to the saturation temperature T pc1 , Condenser outlet tube temperature T def1 , record the running time...

Embodiment 2

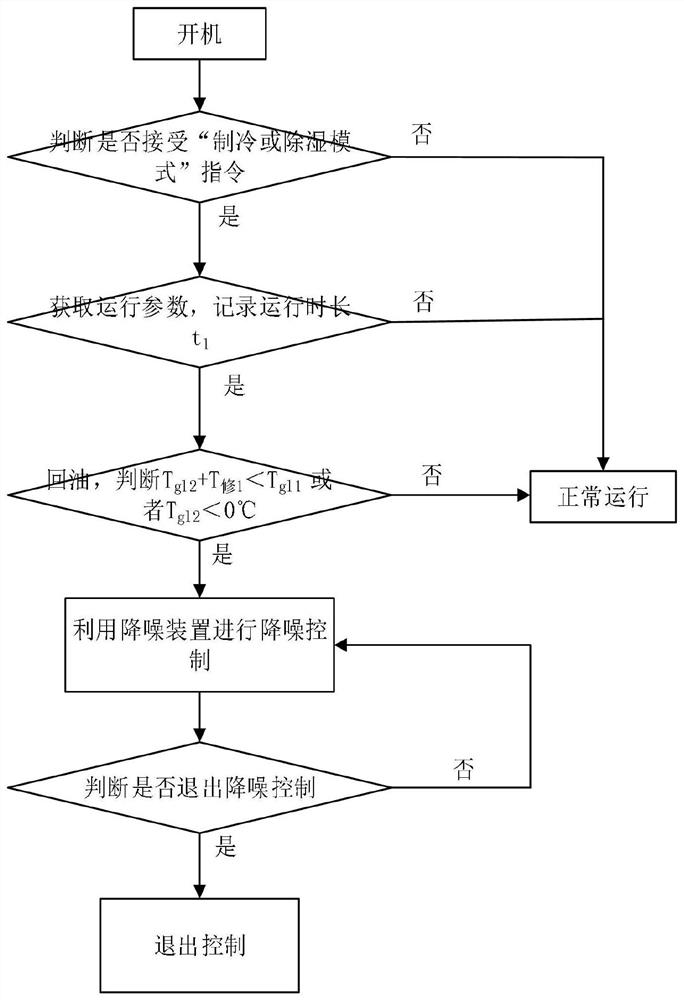

[0041] like figure 2 As shown, a multi-line oil return noise reduction control method includes the following steps:

[0042] S1. Power on, multi-connection to judge whether to accept the "cooling or dehumidification mode" command;

[0043] For multi-connection, if the "cooling or dehumidification mode" command is received after starting up, go to step S2; if the "heating or ventilation mode" command is received, the system operates normally.

[0044] S2. Obtain the multi-line operation parameters and record the operation time t 1 ;

[0045] The operating parameters include indoor ambient temperature T ai , Outdoor ambient temperature T ao , every Δt 0 Get Exhaust High Pressure P d1 , Suction low pressure P s1 , the high pressure corresponds to the saturation temperature T pc1 , Condenser outlet tube temperature T def1 , the valve step value PMV of each internal unit 0 , the speed of the external fan is n, and the operating frequency of the compressor is f 2 . Pref...

Embodiment 3

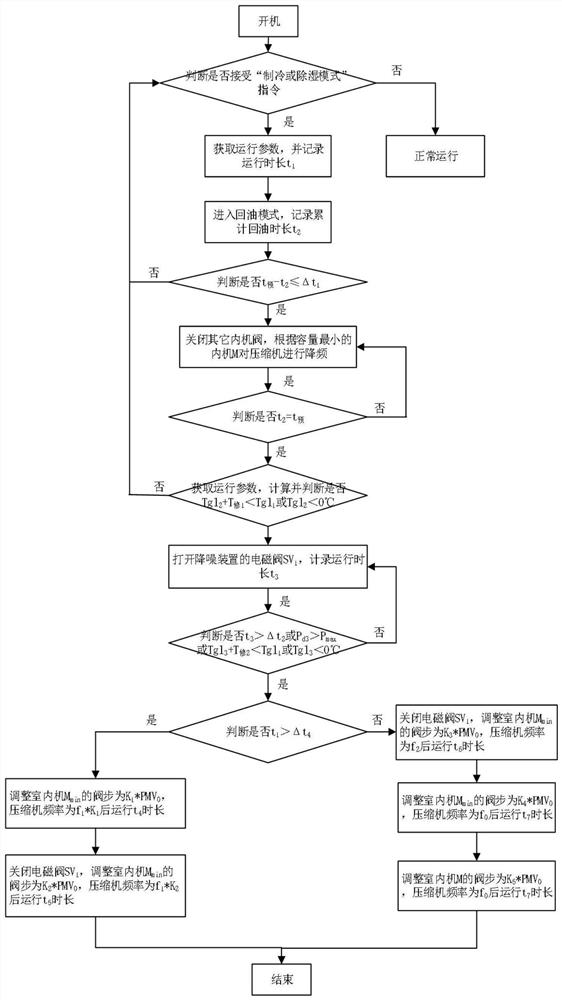

[0057] like image 3 As shown, a multi-line oil return noise reduction control method includes the following steps:

[0058] S1. Turn on the machine and judge whether the multi-connector accepts the command of "cooling or dehumidification mode";

[0059] S2. Obtain the multi-line operation parameters and record the operation time t 1 ;

[0060] The operating parameters include indoor ambient temperature T ai , Outdoor ambient temperature T ao , every Δt 0 Get Exhaust High Pressure P d1 , Suction low pressure P s1 , the high pressure corresponds to the saturation temperature T pc1 , Condenser outlet tube temperature T def1 , the valve step value PMV of each internal unit 0 , the speed of the external fan is n, and the operating frequency of the compressor is f 2 . Preferably, the Δt 0 It is set according to experience value, for example, 4-8s.

[0061] Calculate the subcooling degree T at this time g11 , that is, before entering the oil return operation in cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com