EGR one-way valve opening pressure and opening degree feedback detection device and method

A technology of opening pressure and opening degree feedback, which is used in measuring devices, mechanical valve testing, and optical devices, etc., can solve the problems that elastic deformation performance cannot be completely consistent, and the pressure and opening degree difference of one-way valve opening and closing, etc. To achieve the effect of simple structure, high detection accuracy and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

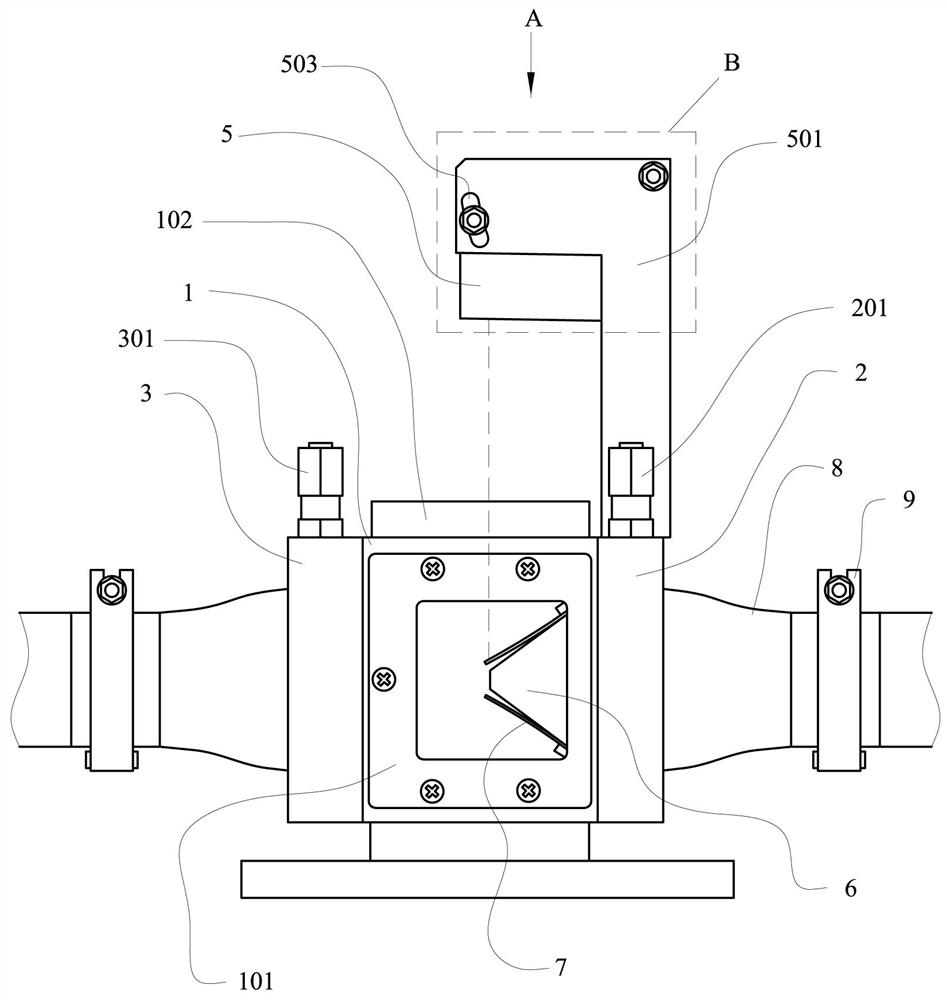

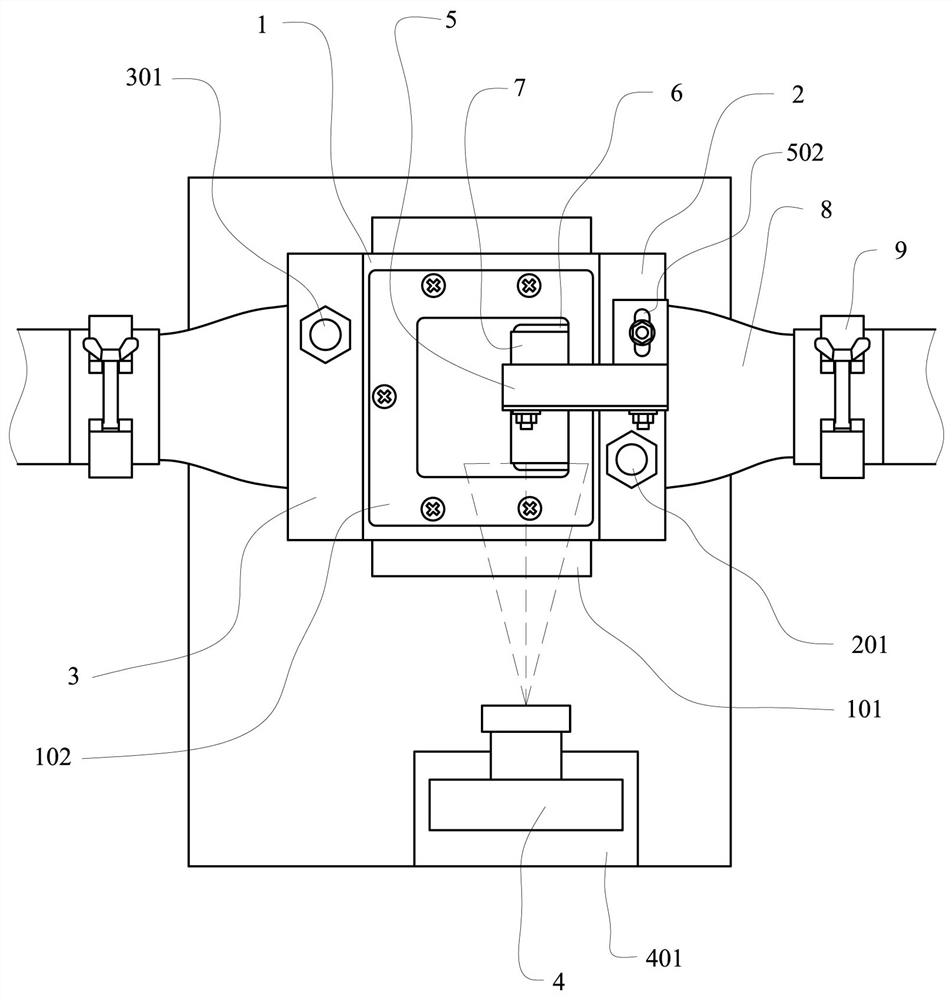

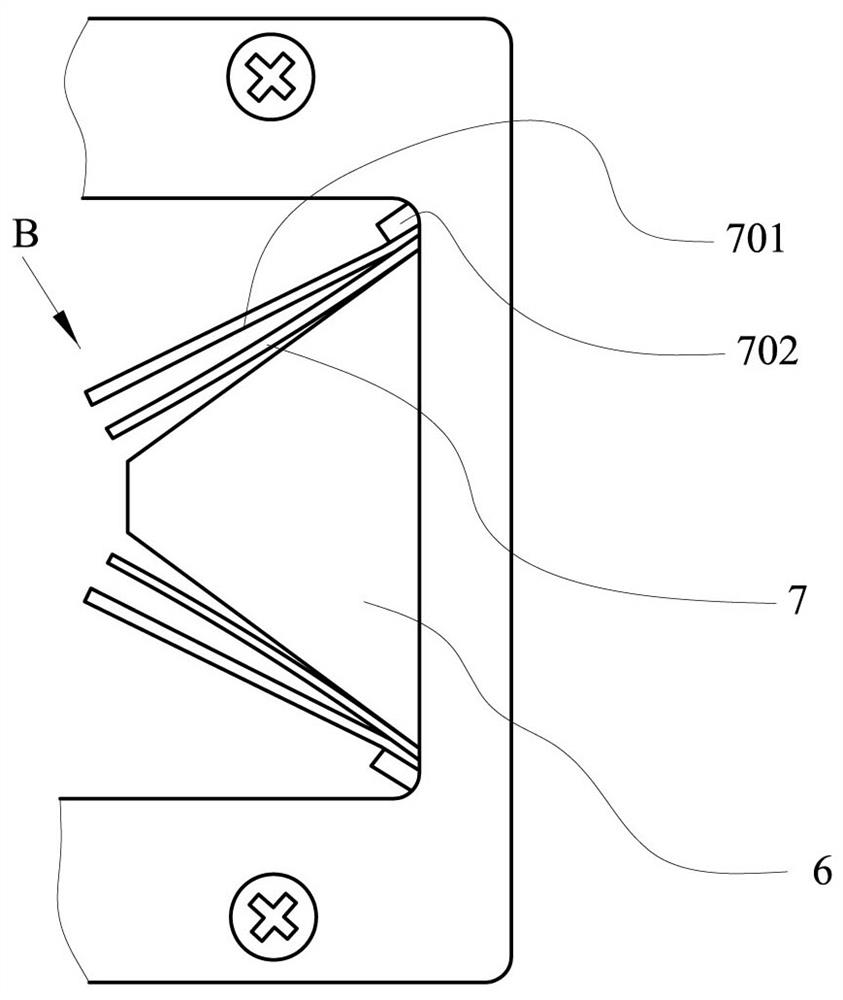

[0024] This embodiment is a kind of EGR check valve opening pressure and opening feedback detection device, such as figure 1 , 2 shown. This embodiment includes: a simulated valve body 1, the front end and the rear end of the simulated valve body are respectively provided with an input flange 2 with an input pressure sensor 201 and an output flange 3 with an output pressure sensor 301, the The input flange is connected to the pressure source through a pipeline, and the output flange is connected to the pressure regulating exhaust port through a pipeline; one side of the simulated valve body is provided with a side transparent observation window 101, and the side is transparently observed There is a camera 4 outside the window, see figure 2 ( figure 1 The camera is not shown in the middle), the top of the simulated valve body is provided with a top transparent observation window 102, and a laser displacement sensor 5 is arranged outside the described top transparent observa...

Embodiment 2

[0037] This embodiment is an improvement of the above-mentioned embodiment, and it is a refinement of the analog valve body in the above-mentioned embodiment. The analog valve body described in this embodiment is a rectangular prism frame made of metal, with the bottom closed and fixedly connected to the base. The side and top are closed by transparent material and fixed with bolts, and the front and rear ends are respectively connected with the input flange and the input flange with bolts.

[0038] The frame of the analog valve body is made of metal profiles or plates, which saves cost and facilitates manufacturing on the basis of ensuring the design cavity. The frame is bent or profiled with a metal plate to form a hexahedral frame, the bottom surface is closed with a metal plate, the front and rear sides are provided with bolt holes connected with the input flange and output flange, and the top and both sides are provided with bolt holes connected with the transparent glass ...

Embodiment 3

[0041] This embodiment is an improvement of the above-mentioned embodiment, and is a refinement of the input flange and the input flange of the above-mentioned embodiment. The input flange and the input flange described in this embodiment are respectively connected to the large mouth end of a section of reducing pipe 8, The small mouth end of the reducer is connected with a section of straight pipe, and the straight pipe section is provided with clamp 9, see figure 1 , 2 .

[0042] The reducer is a tube with a large end and a small end, which is used for diffusing or collecting flow. The transition of the reducer is used to match the gas flow with the volume flow of the one-way valve, the air pressure is stable, and the feedback data is accurate. .

[0043] Using the clamp connection, it is faster and more convenient to assemble or disassemble the pipeline, and it is convenient to replace the reed under test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com