Ultraviolet wide-spectrum maskless photoetching imaging system and photoetching machine

A maskless lithography and imaging system technology, applied in the field of ultraviolet wide-spectrum maskless lithography imaging systems and lithography machines, can solve the problems of difficult correction of chromatic aberration of magnification, low transmittance, small depth of focus, etc., to achieve High operational stability, high transmittance, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0051] Embodiments of the present invention will be described in detail below, and embodiments of the present invention will be described in detail below with reference to the embodiments described in detail below.

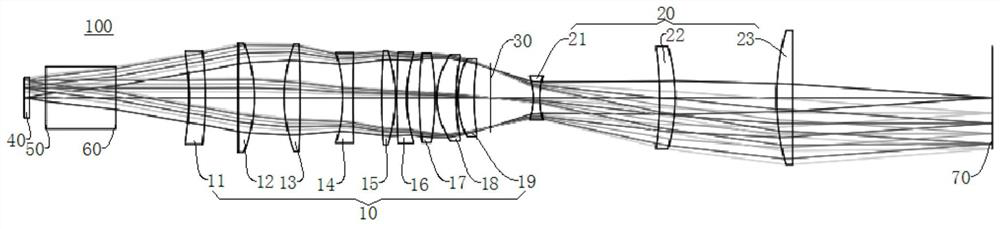

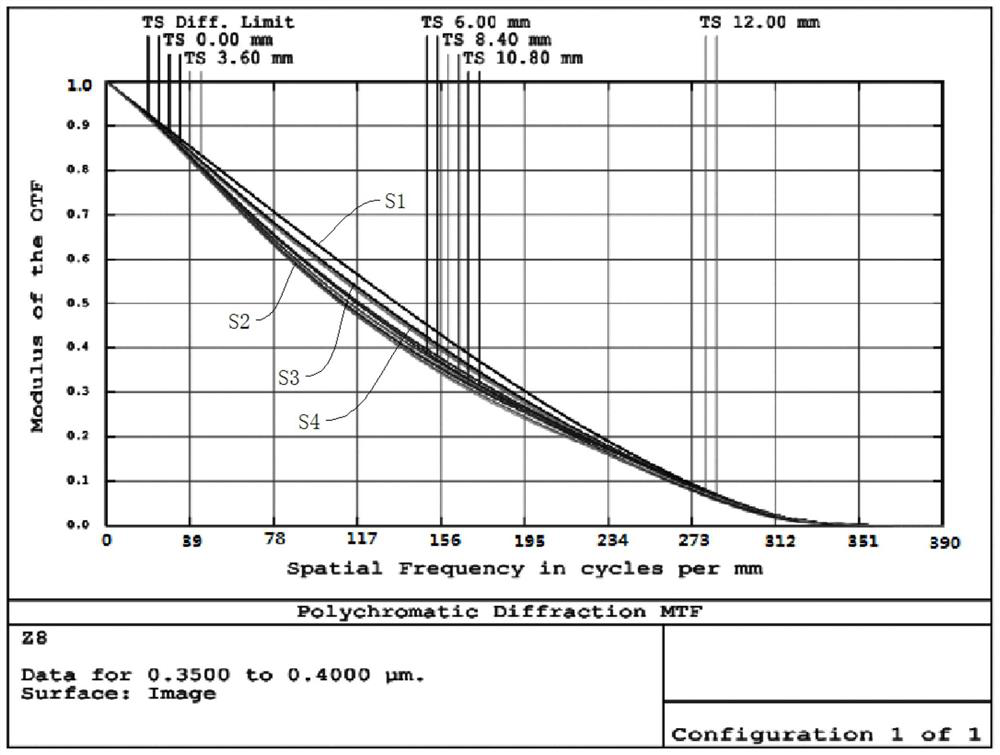

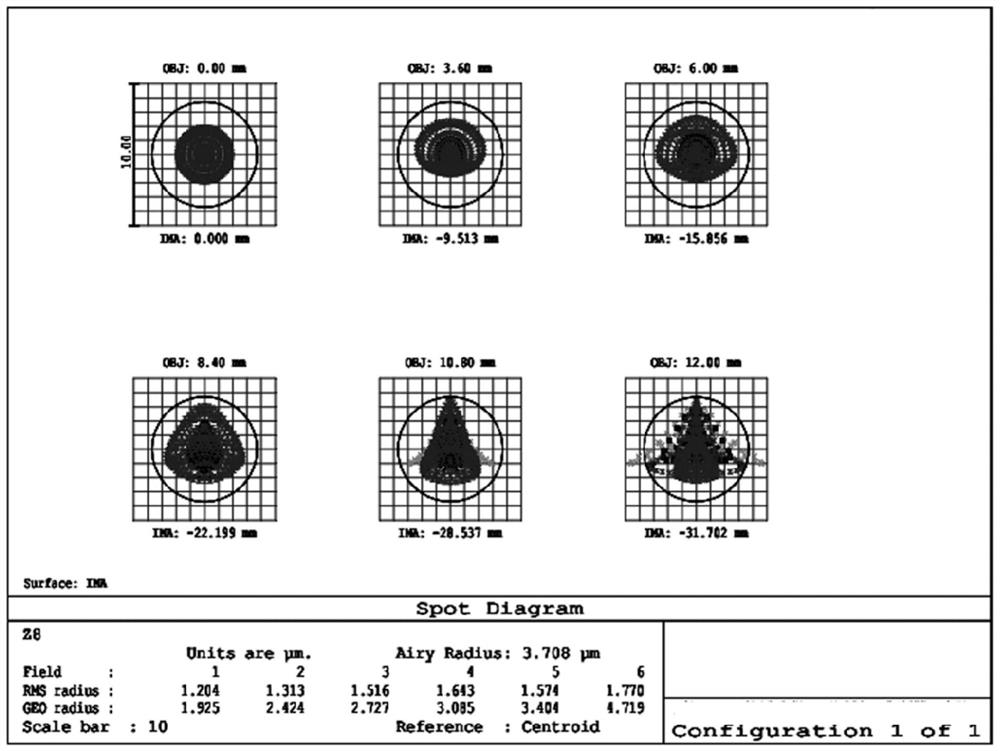

[0052] Below Figure 1 - Figure 4 A ultraviolet wide spectroscopy, an ultraviolet wide spectroscopy, in accordance with an embodiment of the present invention, an ultraviolet wide spectrum-free mask photolithography imaging system 100 includes a first lens assembly 10, a stop 30, and a second lens assembly 20. The following is applied to the photolithography machine as an example of an ultraviolet width spectroscopy as an example, but does not use a limit to this.

[0053] Specifically, if figure 1 As shown, the first lens assembly 10 includes: a first lens 11, a second lens 12, a third lens 13, a fourth lens 14, a fifth lens 15, a sixth lens 16, a seventh lens 17, an eighth lens 18, The ninth lens 19, the second lens assembly 20 includes: tenth lens 21, the eleventh l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap