Work order management method, device and equipment and readable storage medium

A work order management and storage medium technology, applied in the field of maintenance, can solve problems such as increasing the burden on maintenance personnel and affecting completion time, and achieve the effects of improving setting efficiency, improving efficiency, and eliminating manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0045] In a first aspect, an embodiment of the present invention provides a work order management device, and the work order management device may be a device with a data processing function such as a personal computer (personal computer, PC), a notebook computer, or a server.

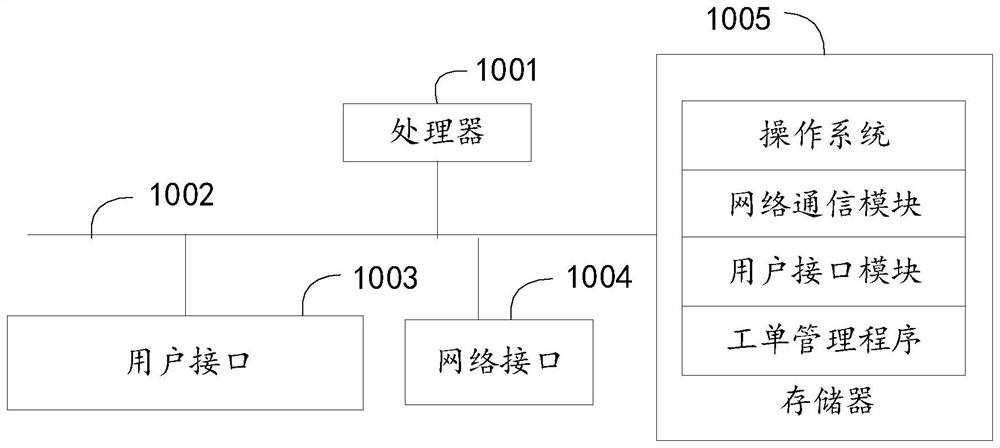

[0046] refer tofigure 1 , figure 1 It is a schematic diagram of the hardware structure of the work order management device involved in the solution of the embodiment of the present invention. In the embodiment of the present invention, the work order management device may include a processor 1001 (such as a central processing unit, CPU), a communication bus 1002, a user interface 1003, a network interface 1004, and a memory 1005. Wherein, the communication bus 1002 is used to realize the connection and communication between these components; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com