Cotton fabric delayed baking non-ironing finishing process

A technology of delayed baking and non-ironing finishing, which is applied to fabric surface trimming, textile material treatment, and continuous processing of textile materials, etc. Improve wrinkles that are difficult to remove, enhance storage stability, and benefit product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 (delayed curing sensitized fabric, process does not contain storage→curing step)

[0036] A cotton fabric delayed baking non-ironing finishing process includes a pretreatment process and a posttreatment process.

[0037] Pretreatment process: singeing → desizing → liquid ammonia → mercerizing → liquid ammonia;

[0038] The specific process of the desizing process is as follows: the fabric is immersed in the enzyme solution → steamed (stacked at 100°C for 20 minutes) → washed with water (95°C) → dried. Conditions: desizing enzyme 3g / L; penetrant 4g / L; chelating agent 2g / L; vehicle speed 70m / min;

[0039] The specific flow of the liquid ammonia process is: cloth feeding→pre-drying→cooling→liquid ammonia treatment (dipping liquid ammonia for 15s→drying)→steaming (95°C)→water washing (95°C)→drying→cloth falling. Conditions: vehicle speed 60m / min; temperature of treatment chamber 80°C; pH value of falling cloth 6;

[0040] The specific process of the mercerizing...

Embodiment 2

[0064] Embodiment 2 (delay baking fabric, technique contains storage→baking step)

[0065] A cotton fabric delayed baking non-ironing finishing process includes a pretreatment process and a posttreatment process.

[0066] Pretreatment process: singeing → desizing → liquid ammonia → mercerizing → liquid ammonia;

[0067] The specific process of the desizing process is as follows: the fabric is immersed in the enzyme solution → steamed (stacked at 100°C for 20 minutes) → washed with water (95°C) → dried. Conditions: desizing enzyme 3g / L; penetrant 4g / L; chelating agent 2g / L; vehicle speed 70m / min;

[0068] The specific flow of the liquid ammonia process is: cloth feeding→pre-drying→cooling→liquid ammonia treatment (dipping liquid ammonia for 15s→drying)→steaming (95°C)→water washing (95°C)→drying→cloth falling. Conditions: vehicle speed 60m / min; temperature of treatment chamber 80°C; pH value of falling cloth 6;

[0069] The specific process of the mercerizing process is as f...

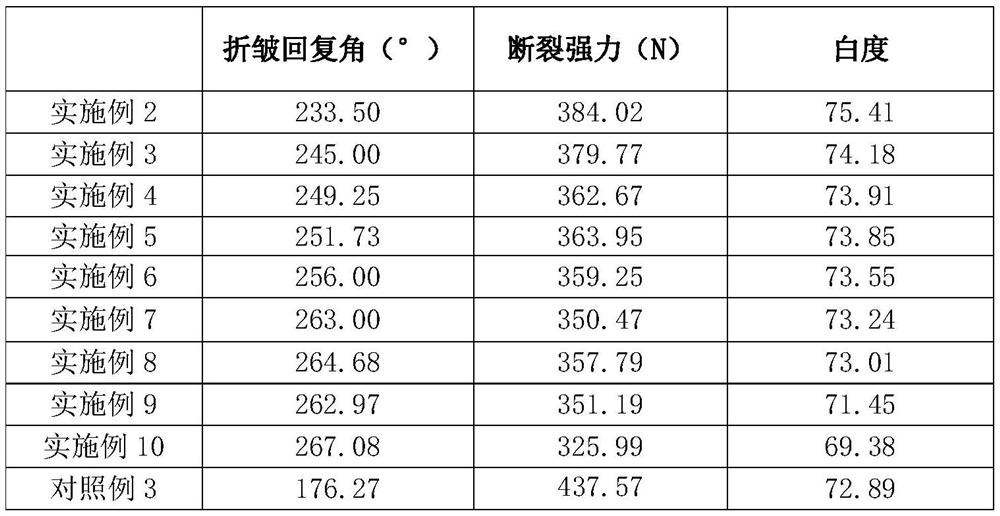

Embodiment 3

[0072] A delay-baking and non-ironing finishing process of cotton fabrics refers to Example 2. The difference between Example 3 and Example 2 is that the 3 minutes of baking in the post-baking finishing process B is adjusted to 6 minutes of baking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com