Airport pavement structure for additionally paving asphalt layer on old cement airport runway and paving method of airport pavement structure

A technology for airport runways and old cement, which is applied to cohesive pavement, roads, roads and other directions paved on site. It can solve the problems of high strength, low-temperature brittle fracture, and poor coordination, so as to reduce the impact and improve friction and adhesion. Good strength and water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

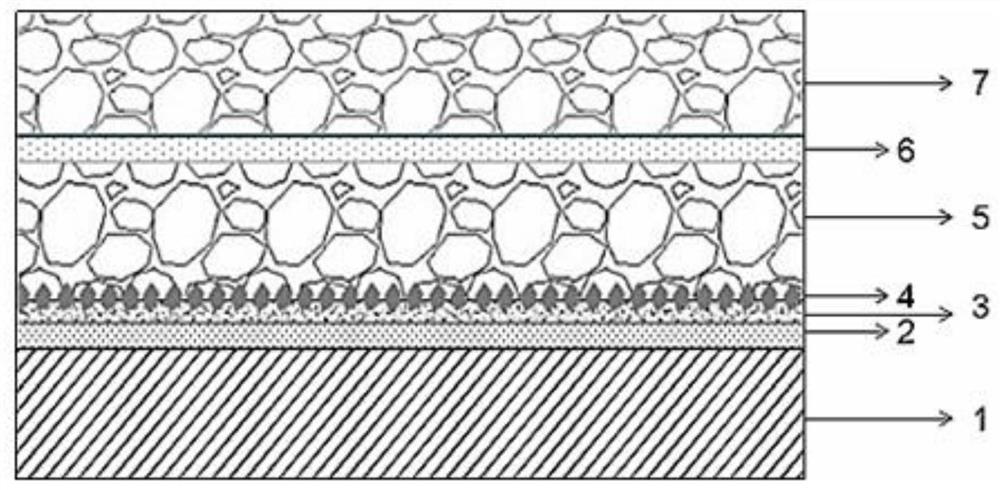

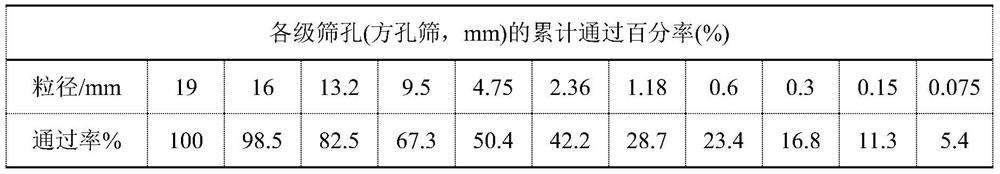

[0041] like figure 1 As shown, the airport pavement structure of the old cement airport runway of the present embodiment with an asphalt layer, including a lower viscoelastic bonding layer 2, a mortar layer 3, and a gravel layer arranged on the old cement concrete layer 1 from bottom to top. 4. Modified asphalt concrete overlay 5, upper interface bonding layer 6 and epoxy asphalt concrete overlay 7; crushed stone layer 3 is embedded between the mortar layer 2 and modified asphalt concrete overlay 5, modified The permanent asphalt concrete overlay layer 5 and the epoxy asphalt concrete overlay layer 7 are bonded through the upper interface bonding layer 6 .

[0042] The lower viscoelastic bonding layer 2 uses pit interface repairing agent, and the bonding strength of the pit interface repairing agent used in this embodiment is 1.2 MPa.

[0043] The mortar layer 3 adopts cement-emulsified asphalt mortar. In this embodiment, the ratio of raw materials used in the cement-emulsifi...

Embodiment 2

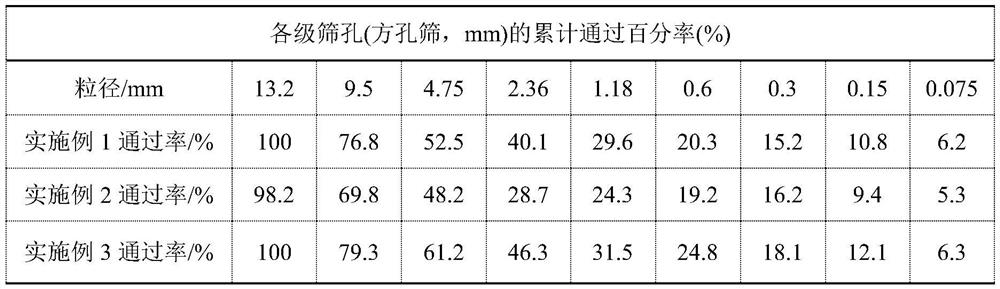

[0068] The airport pavement structure of the used old cement airport runway overlay asphalt layer in embodiment 2, except that the aggregate gradation of the early strength type epoxy asphalt concrete EA-13 of the epoxy asphalt concrete overlay layer 7 is different from that of embodiment 1 Except, the preparation of all the other materials and the paving method are all the same as in Example 1.

[0069] In this embodiment, the aggregate gradation of the early-strength epoxy asphalt concrete EA-13 of the epoxy asphalt concrete overlay layer 7 is shown in Table 3.

Embodiment 3

[0071] The used airport pavement structure of the old cement airport runway overlay asphalt layer used in embodiment 3, except that the aggregate gradation of the early strength type epoxy asphalt concrete EA-13 of the epoxy asphalt concrete overlay layer 7 is different from that of embodiment 1 Except, the preparation of all the other materials and the paving method are all the same as in Example 1.

[0072] In this embodiment, the aggregate gradation of the early-strength epoxy asphalt concrete EA-13 of the epoxy asphalt concrete overlay layer 7 is shown in Table 3.

[0073] Table 3 Aggregate gradation of early strength epoxy asphalt concrete EA-13 in the example

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com