Foundation pile drilling machine

A technology for drilling rigs and foundation piles, which is applied in the direction of rotary drilling rigs, earthwork drilling, drilling equipment, etc. It can solve the problems of easy swing and damage of auger drill pipes, and achieve vertical downward drilling, slow down friction, and lift The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The embodiment of the application discloses a foundation pile drilling machine.

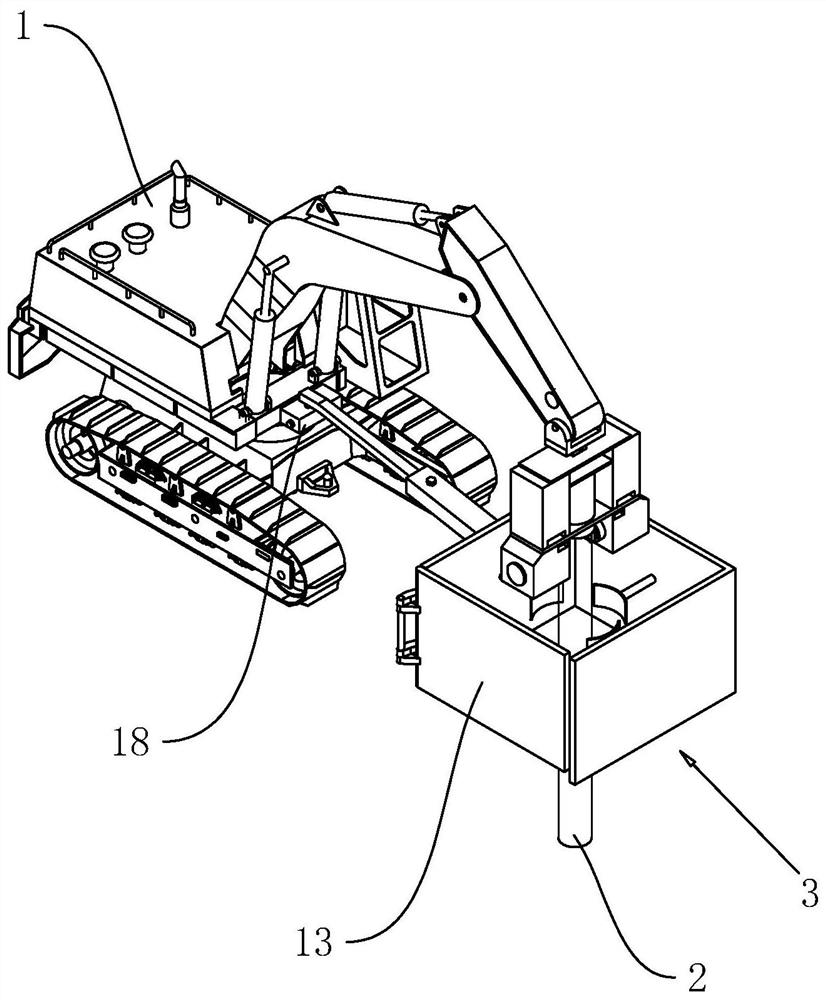

[0033] refer to figure 1 , a foundation pile drilling rig, including a body 1 and a drill pipe 2, the body 1 is the same as the body 1 of an excavator, and a clamp for clamping the drill rod 2 is fixedly installed on the mechanical arm of the body 1, and the clamp can make the clamped The drill pipe 2 rotates, and during the piling process, the drill pipe 2 is hoisted in advance by the mechanical arm to be in a vertical state.

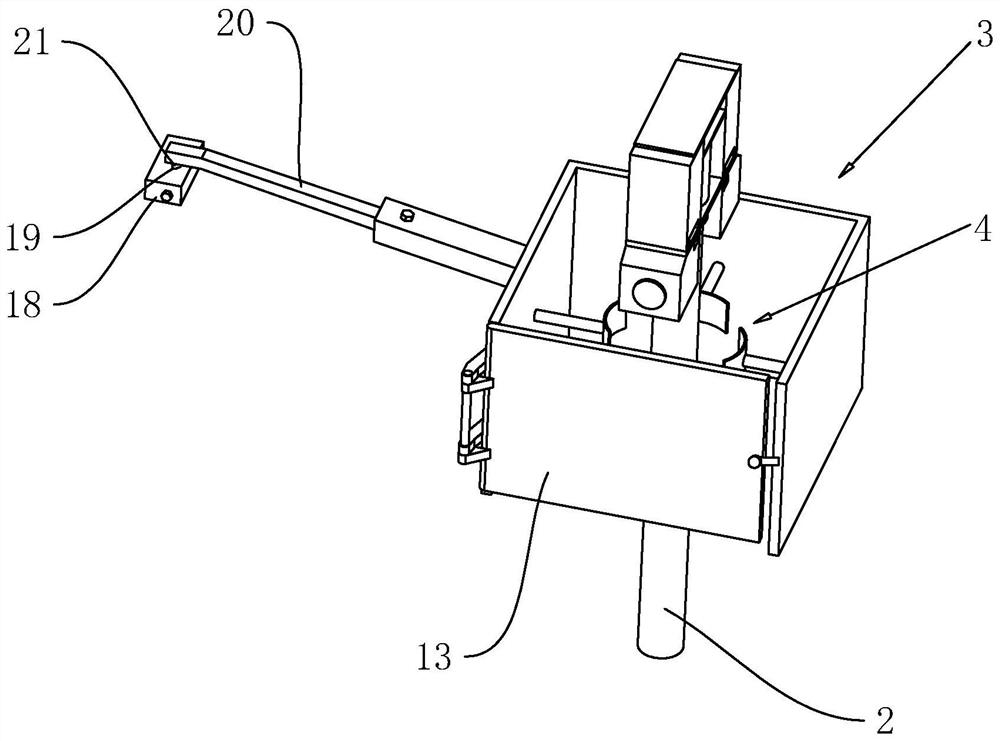

[0034] refer to figure 1 and figure 2 , the bottom of the drill pipe 2 is provided with a support frame 3, the support frame 3 is a rectangular frame, the support frame 3 is fixed on the ground, the side wall of the body 1 is provided with a mounting seat 18, and the mounting seat 18 is fixed at the lower end of the mechanical arm of the body 1 On the side wall, during the rotation process of the mechanical arm of the body 1, the mounting seat 18 rotates synchr...

Embodiment 2

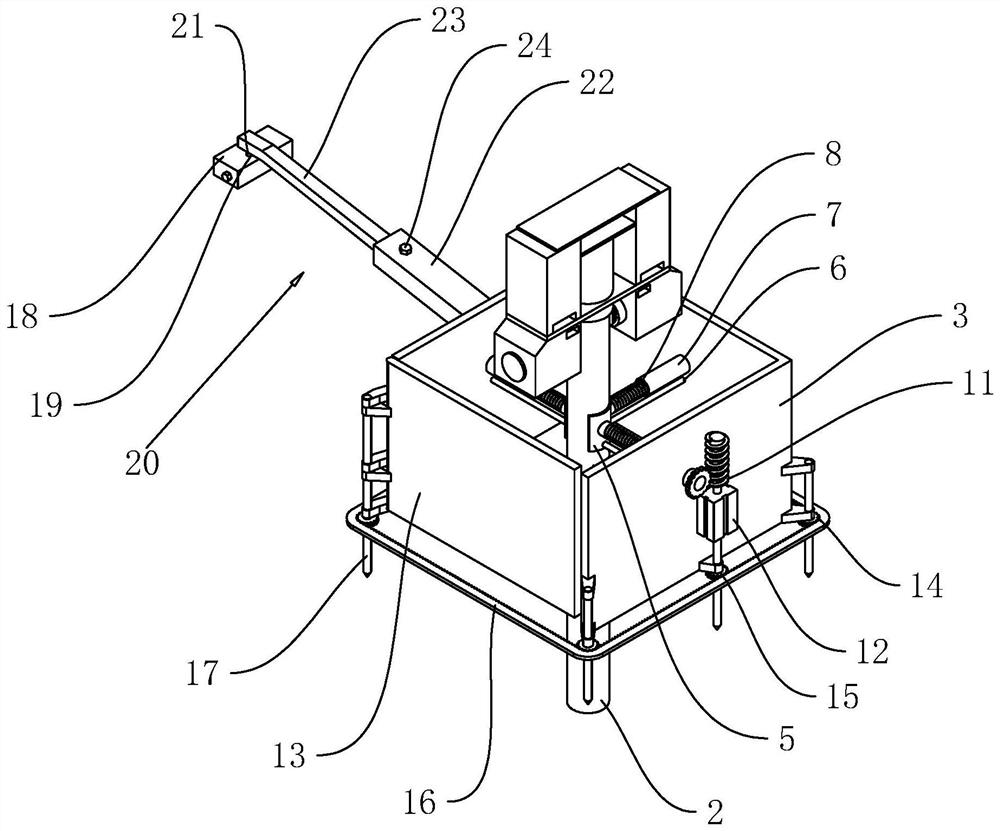

[0039] refer to image 3 and Figure 4The difference between the second embodiment and the first embodiment is that the limit assembly 4 includes an arc-shaped plate 5, a guide rod 6, a guide tube 7, a screw rod 8 and is arranged at the end of the guide tube 7 away from the arc-shaped plate 5 to drive the guide rod 6 to slide There are three driving parts 9 and three arc-shaped plates 5, and the three arc-shaped plates 5 are respectively arranged on the inner side walls of the support frame 3 without openings, and several balls 25 are arranged on the inner walls of the arc-shaped plates 5 to rotate evenly at intervals. During the construction process, where the outer wall of the ball 25 meets the outer wall of the drill pipe 2, the ball 25 slows down the friction between the inner wall of the arc-shaped plate 5 and the outer wall of the drill pipe 2, making it easier for the drill pipe 2 to drill vertically downward. The rod 6 slides on the support frame 3 along the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com