Shaft end sealing structure and sealing performance test device for deep water reducer

A technology of shaft end sealing and testing device, which is used in liquid/vacuum measurement for liquid tightness, engine sealing, and measurement of fluid acceleration and deceleration rates. Affecting the sealing performance and life of mechanical seals, achieving the best sealing performance and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to detail the technical content, structural features, achieved goals and effects of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

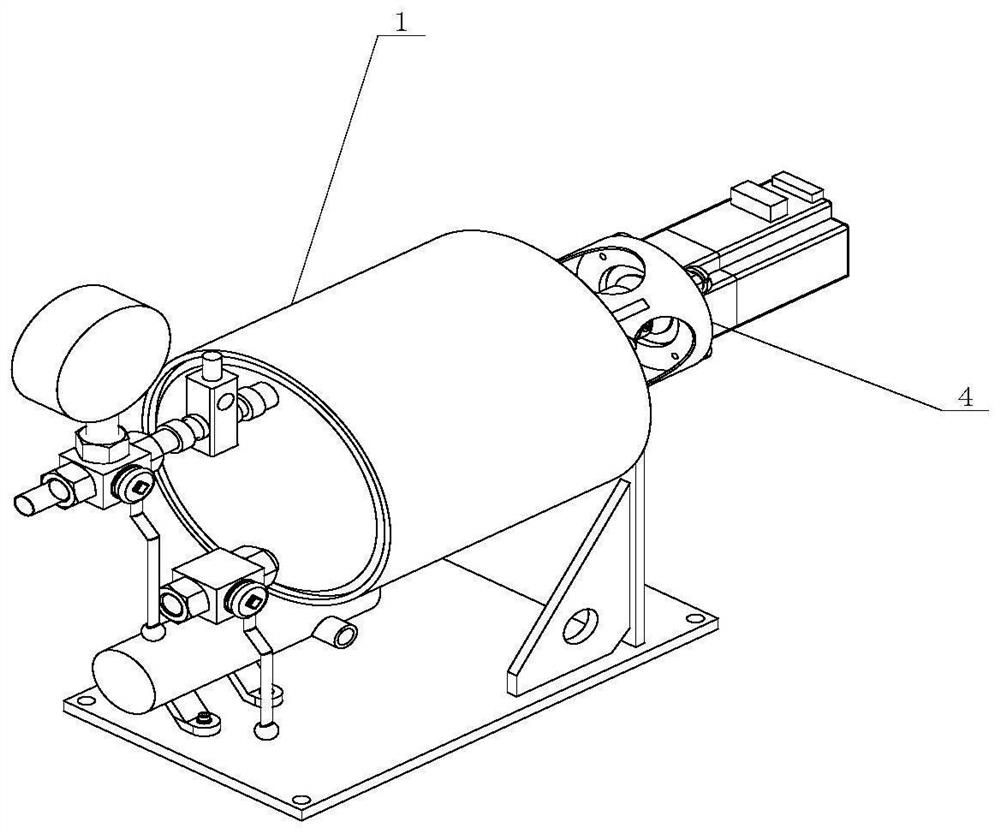

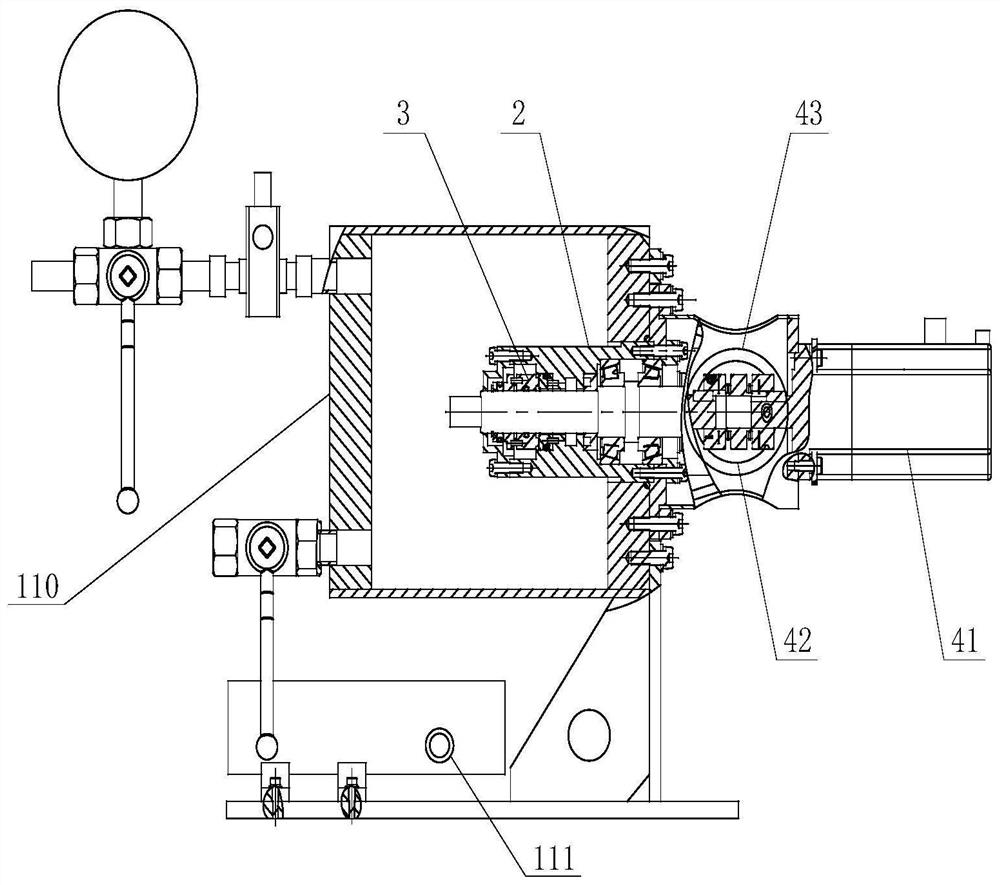

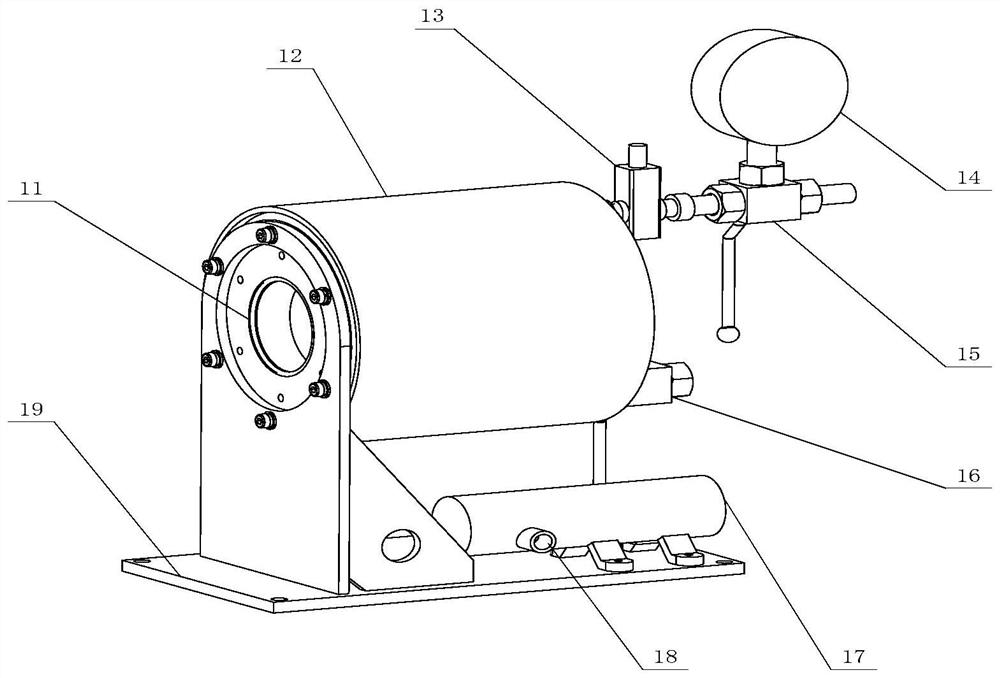

[0030]Shaft end sealing structure and sealing performance test device for deep water reducer, such as figure 1 and figure 2 As shown, it includes a pressure vessel assembly 1 , an outer shell assembly 2 , a mechanical seal assembly 3 and a drive assembly 4 . The first end of the outer casing assembly 2 is located inside the pressure vessel assembly 1, the second end of the outer casing assembly 2 is fixedly connected to the first end of the second head of the pressure vessel assembly 1, and the mechanical seal group 3 is located in the outer casing assembly 2. Inside, and fixedly connected with the rotating shaft 21 of the outer shell assembly 2 , the bell housing 42 of the drive assembly 4 is connected with the second end of the second head 11 of the pressure vess...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com