Liquid crystal display panel and electronic equipment

A technology for liquid crystal display panels and electronic equipment, applied in nonlinear optics, instruments, optics, etc., can solve the problems of low reflectivity and high production cost of liquid crystal display panels, achieve increased area, reduce mold opening costs and production costs, and reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

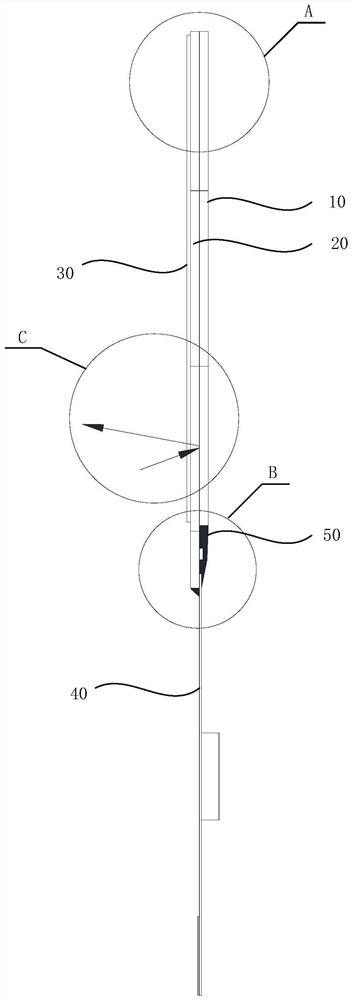

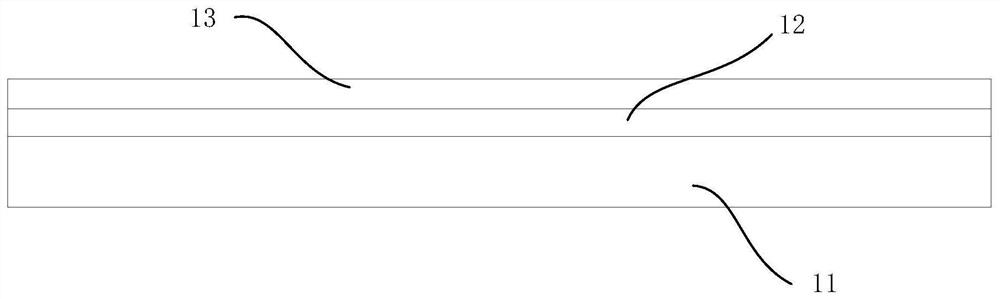

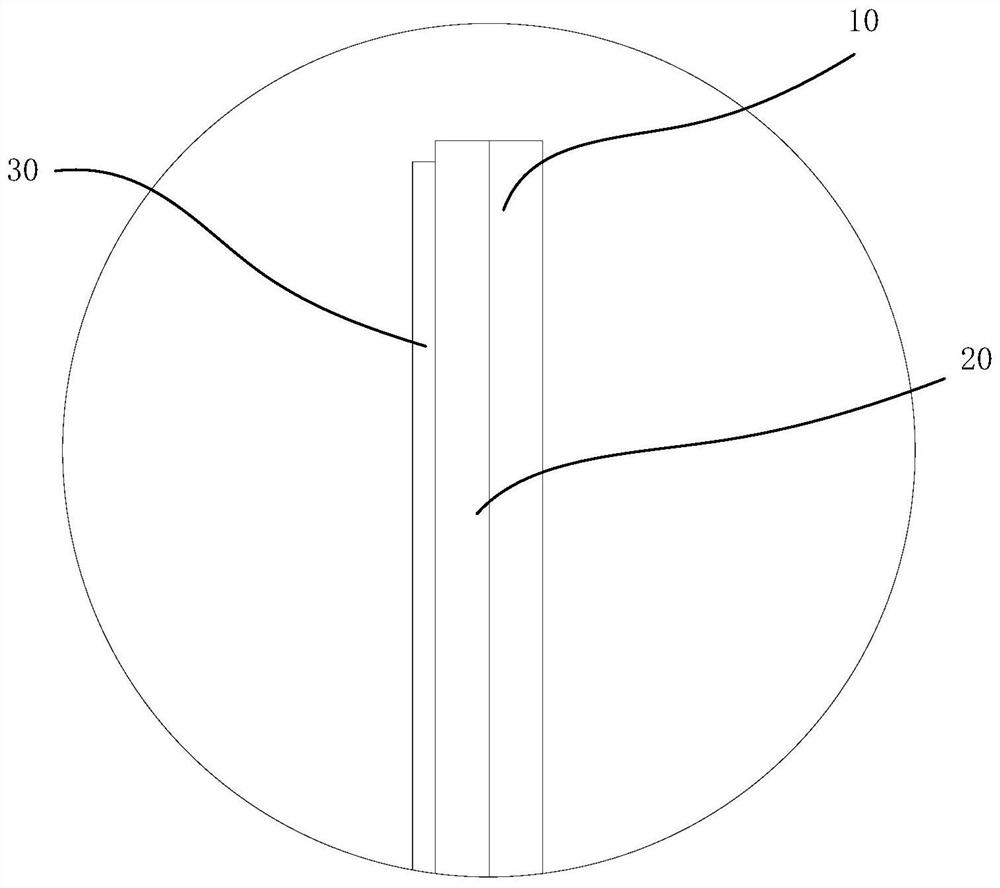

[0034] Such as figure 1 , image 3 and Figure 4 As shown, the liquid crystal display panel provided by the present invention includes a reflective module, and the reflective module includes a filter substrate 10 and an array substrate 20 arranged in layers.

[0035] The filter substrate 10 includes a plurality of filter units distributed in an array, no black matrix is arranged between adjacent filter units, and the adjacent filter units are in direct contact with each other. Since the setting of the black matrix has a great influence on the pixel aperture ratio. Therefore, the black matrix is removed, the area of reflected light is increased, and the mold opening cost and production cost of the filter substrate 10 are reduced.

[0036] The liquid crystal display panel further includes: a polarizer 30 at least partially covering the array substrate; a flexible circuit board 40 at least partially overlapping the array substrate 20 ; a driving integrated circuit 50 at ...

Embodiment 2

[0043] This embodiment provides an electronic device, including the liquid crystal display panel in Embodiment 1.

[0044] It also includes a backlight module. The backlight module is arranged on the side of the filter substrate 10 away from the array substrate 20. The backlight module is used to provide a backlight for electronic equipment.

[0045] Such as Figure 5 As shown, the backlight module includes a light source and a light guide plate. The light emitted by the light source is guided through the light guide plate, passes through the polarizer 30 and the filter substrate 10 in the liquid crystal display panel, and is reflected from the array substrate 20 . The screen reflectivity of this electronic device is high, the cost is low, and it has good market competitiveness.

[0046] The technical scheme adopted in the present invention can achieve the following beneficial effects:

[0047] (1) There is no black matrix between adjacent filter units on the filter substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com