A kind of rubber tapping knife for rubber tapping machine

A rubber tapping knife and rubber tapping machine technology, applied in the fields of application, agriculture, forestry, etc., can solve the problems of inconvenient tapping, returning the knife and changing lines, etc., and achieve the effects of improving precision, reducing uneven depth, and improving applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

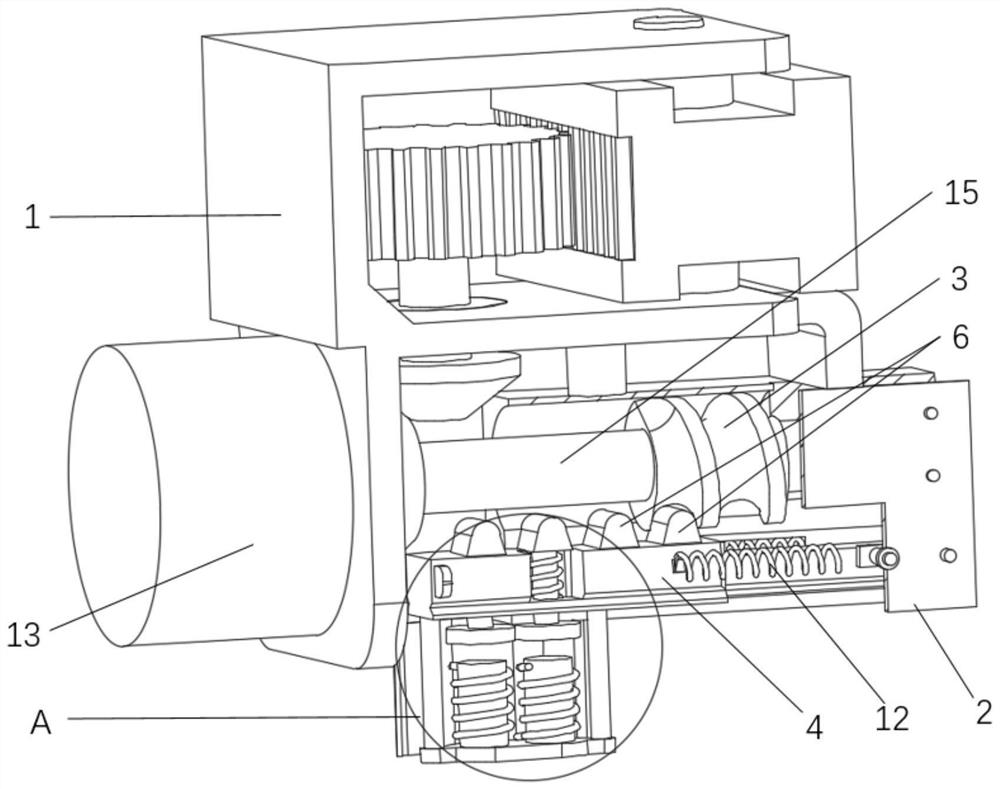

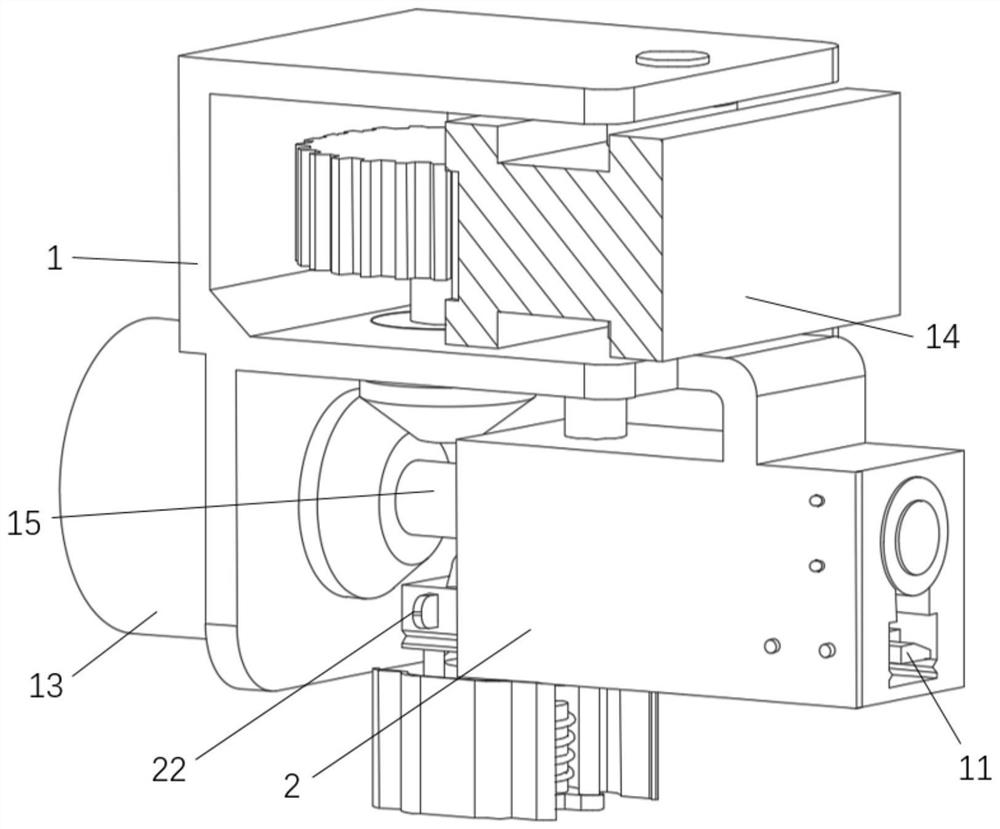

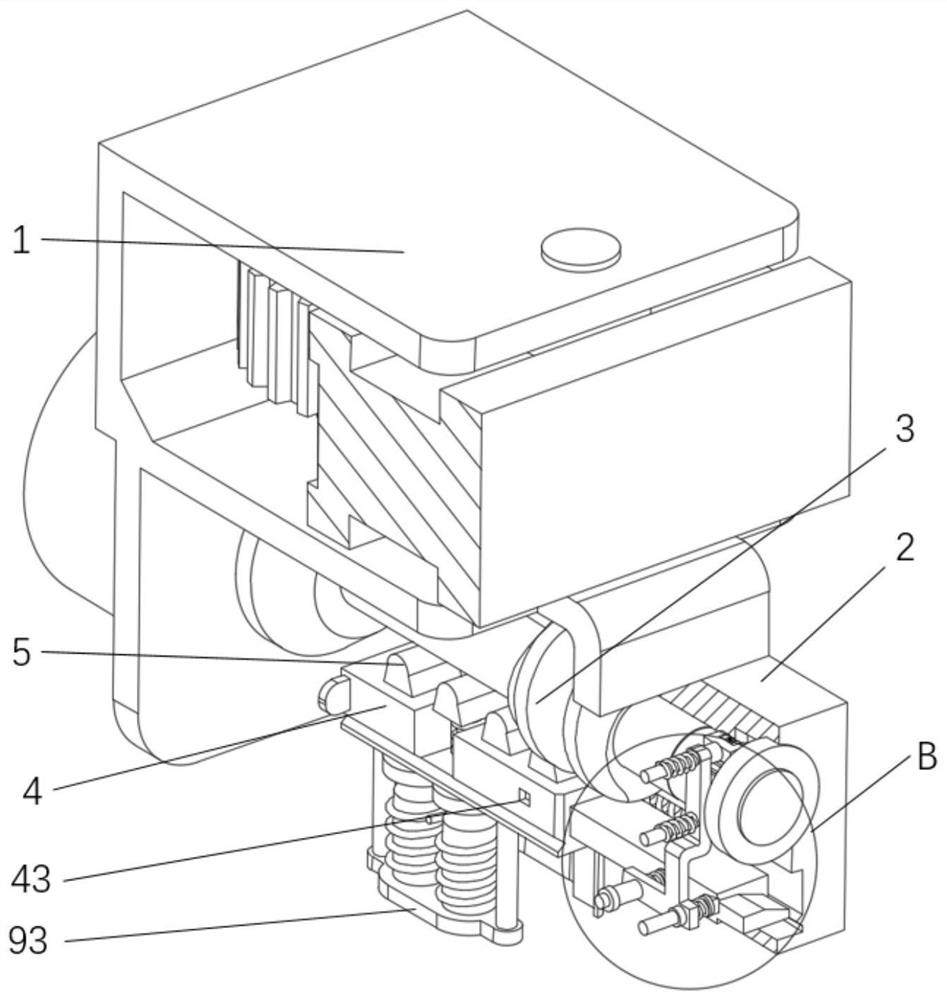

[0031] like Figure 1 to Figure 7 As shown, the present invention provides a rubber tapping knife for a rubber tapping machine, comprising a frame 1 that can move on a spiral track 14, the lower part of the frame 1 is connected to a limit slide 2; the limit slide 2 is provided with a rotatable The worm 3 and the slidable rack 4, the end of the rack 4 is provided with a cutter 11; the rack 4 is provided with a number of retractable elastic teeth 5 for adjusting the extension of the cutter 11. There are also a number of fixed teeth 6 for pushing the cutter 11 forward and backward, and the elastic teeth 5 and the fixed teeth 6 are connected with the worm 3 in a drive, so as to make the worm 3 rotate through the drive connection between the worm 3 and the rack 4 Drive the rack 4 to move forward and backward in a straight line, thereby driving the rubber tapping tool 11 to take out and retract; the limit slide 2 is provided with a rotary unlocking device 7 for unlocking the rack 4 ...

Embodiment 2

[0036] like Figure 1 to Figure 7 As shown, combined with the technical solution of Embodiment 1, in this embodiment, spring grooves 21 are provided on both sides of the limit slideway 2, the first spring 12 is provided in the spring groove 21, and the ends of the rack 4 are provided on both sides. There is a protrusion 42 that slides against the first spring 12, so that the first spring 12 can reverse the sliding out of the rack 4, so that when the elastic teeth 5 retract into the rack 4, the rack 4. Rebound under the force of the first spring 12 to make the teeth abut on the worm 3 quickly, so as to realize the rapid retraction of the cutter 11. For the rubber tapping method when the cutter returns to the bottom, that is, the cutter 11 starts from the bottom. The top method of spiral cutting around the tree and then wrapping and returning to the position, and the rapid closing of the knife can avoid the returning cutting of the bark by the knife 11.

[0037] Specifically, t...

Embodiment 3

[0041] like Figure 5 and Figure 7 As shown, combined with the technical solution of Embodiment 2, in this embodiment, the sliding rod 83 includes a first sliding rod 831 and a second sliding rod 832, the first sliding rod 831 is connected with the first elastic locking teeth 81, and the second sliding rod 832 is connected with the second elastic locking tooth 82; the first sliding rod 831 is threadedly connected with an adjusting solenoid 85 for adjusting the expansion and contraction amount of the first elastic locking tooth 81 along the rod direction, so as to adjust the first elasticity through the adjusting solenoid 85 The expansion and contraction amount of the locking teeth 81 along the rod direction is used to realize the locking of the first elastic locking teeth 81 and the locking teeth in both forward and backward directions or locking in the backward direction.

[0042] When the adjusting solenoid 85 is rotated to cause the first sliding rod 831 to stretch the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com