Screening device for snake gourd seed processing

A screening device and the technology of trichosanthes, which are applied in the field of screening devices for the processing of trichosanthes, can solve the problems of low efficiency and manpower consumption, and achieve the effects of ensuring screening efficiency, improving production efficiency, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

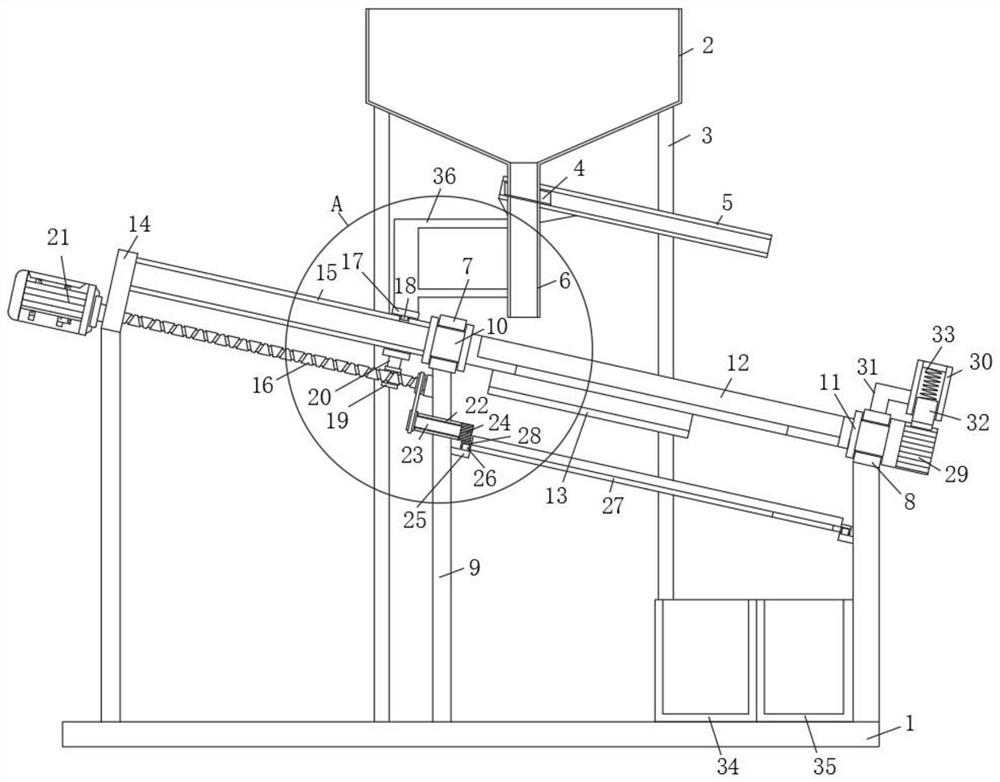

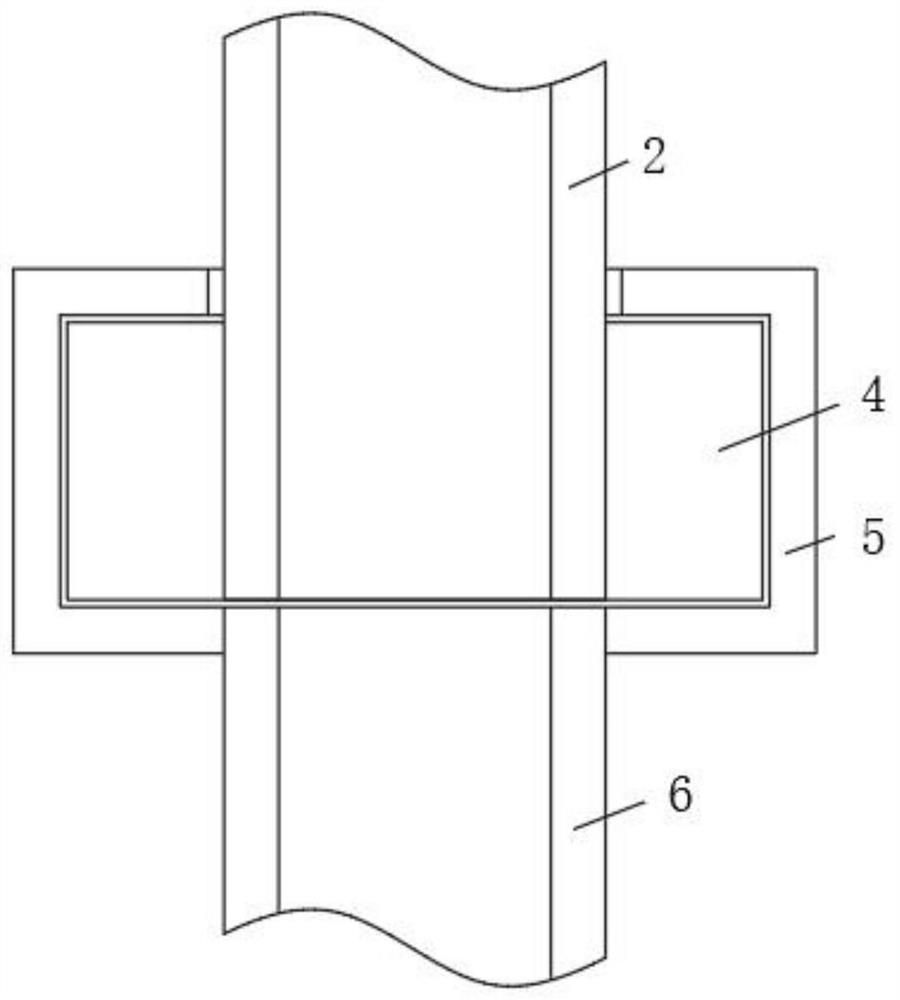

[0027] refer to Figure 1-4 , a screening device for processing Trichosanthes, comprising a bottom plate 1, a feed hopper 2 is arranged vertically above the bottom plate 1, a support column-3 is arranged between the feed hopper 2 and the bottom plate 1, and the bottom of the feed hopper 2 The outer edge of the end is fixedly connected with an inclined track ring 4, and the outer side of the inclined track ring 4 is provided with a blocking material inclined sleeve 5, and the bottom of one end of the blocking material inclined sleeve 5 is provided with a through hole and is fixedly connected with a discharge pipe 6 , between the base plate 1 and the feed hopper 2, a rotating seat 7 and a rotating seat 8 are arranged, and a rotating part 10 and a rotating part 11 are respectively installed in the rotating seat 7 and the rotating seat 8, and the rotating part 10 A top sieve plate 12 is arranged between the rotating member 2 11, and a material guide bottom plate 13 is installed on...

Embodiment 2

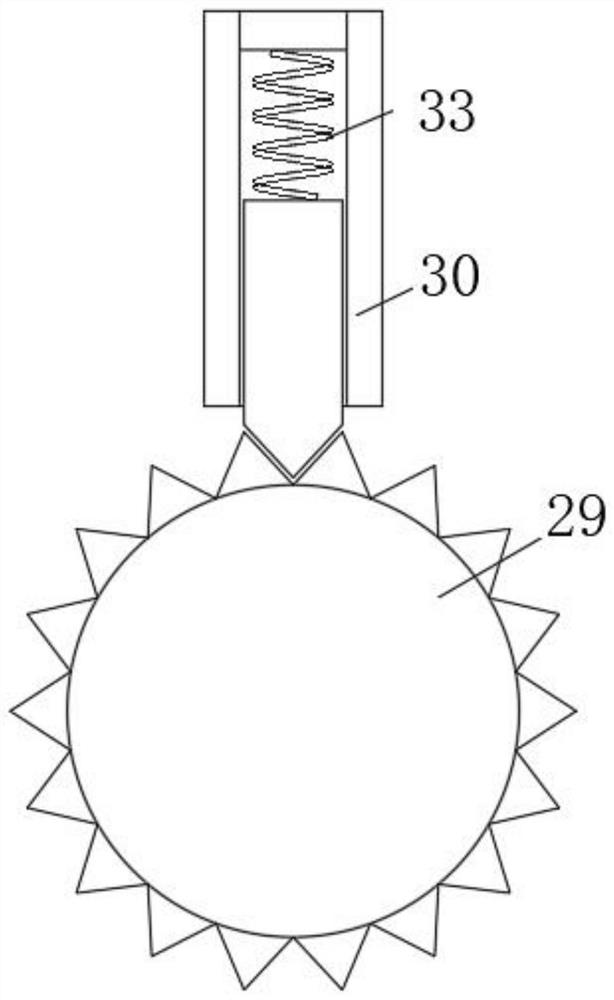

[0030] like Figure 1-4As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the vibrating mechanism includes a vibrating gear seat 29 coaxially fixedly connected with the rotating member 11, and the top of the vibrating gear seat 29 is provided with a rail cylinder 30, and the rail cylinder 30 The single opening structure of the bottom opening, the track cylinder 30 is slidably connected with a sharpened hammer rod 32, the top of the sharpened hammered rod 32 is provided with a spring 33, the bottom end of the sharpened hammered rod 32 is in contact with the vibrating tooth seat 29, and the track cylinder 30 A support rod 31 is fixedly connected with the rotating seat 2 8 .

[0031] In this embodiment, during the turning over of the top sieve plate 12, the rotating part 11 drives the vibrating tooth seat 29 to rotate, and the sharp split hammer rod 32 connected to the outer side of the vibrating tooth seat 29 moves back and forth in the track cyl...

Embodiment 3

[0033] like Figure 1-4 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the top side of the bottom plate 1 is provided with receiving box 1 34 and receiving box 2 35 side by side, and the bottom plates of the top sieve plate 12 and the material guide plate 27 are both Be provided with discharge port and be positioned at the vertical top of receiving box 2 35, the board body of top sieve plate 12 is provided with sieve hole, material guide bottom plate 13 is U-shaped structure and is positioned at the bottom of sieve hole, and the bottom of material guide bottom plate 13 The bottom end is positioned at the vertical bottom of the receiving box one 34, and the feed hopper 2 is positioned at the vertical top of the top sieve plate 12 top.

[0034] In this embodiment, raw materials of different sizes are collected, and the raw materials with larger sizes and the raw materials stuck in the sieve holes are collected in the receiving box 2 35, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com